One-piece Caravan Composite Panels

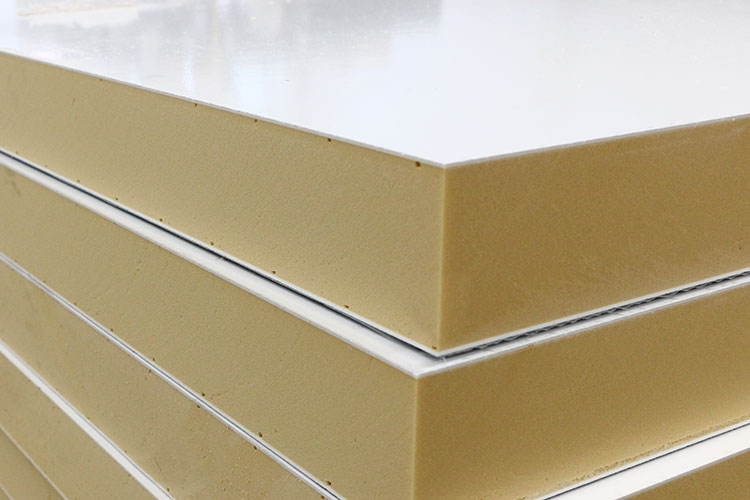

One-piece caravan composite panels are composed of multiple layers of different materials, usually divided into outer layers, insulation layers, and inner layers. Unlike the traditional framed caravan body, the side panels, roof, and floor of the caravan are produced separately and then assembled together.

The advantages of one-piece composite panels are reflected in:

- Lightweight: The one-piece RV composite panel optimizes the structure, uses less composite materials, realizes the lightweight of the RV, and saves expenditure costs.

- Rapid assembly: No more assembly personnel are needed, usually 2~3 people can quickly assemble a RV body within half a day by cooperating with each other, which greatly shortens the RV production time.

Basic Specifications

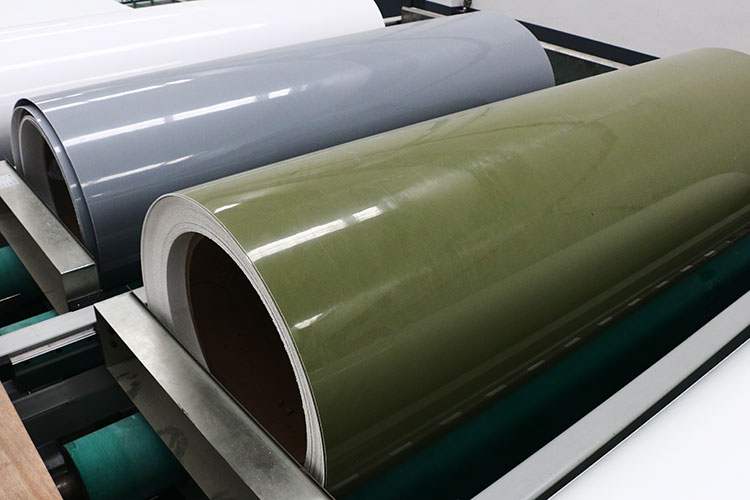

- Skin material: High-gloss gelcoat GRP sheet (thickness 1.8~3.0mm).

- Surface Color: RAL color series.

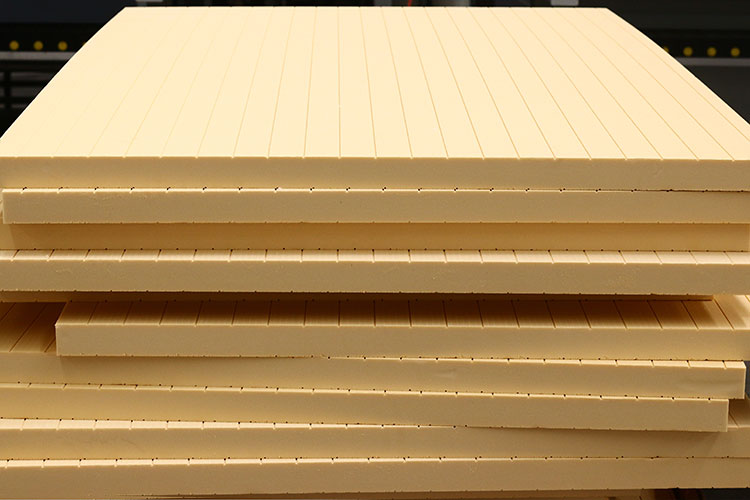

- Core material: XPS foam (10~120mm).

- Length: within 12m.

- Width: within 3.2.

- Flame Retardant: B2.

- Anti-ultraviolet: F1.

Features

The caravan composite panel adopts GRP foam sandwich structure, which has the following characteristics:

- The surface of GRP adopts high-gloss anti-ultraviolet coating, and the surface is smooth and flat, which can reflect most of the sunlight, which makes the composite panel basically not absorb any external heat.

- The glass fiber content in the GRP sheet is more than 70%, and the GRP thickness can reach 3mm, which is strong and rigid.

- The core material is closed-cell XPS foam with high compression resistance, which does not absorb water and has good thermal insulation effect, and can withstand temperature fluctuations of -20~+70°C.

- Use high-quality lightweight environmentally friendly glue as an adhesive, no odor, no formaldehyde release; XPS foam core and GRP sheet are tightly bonded, and it is not easy to delaminate.

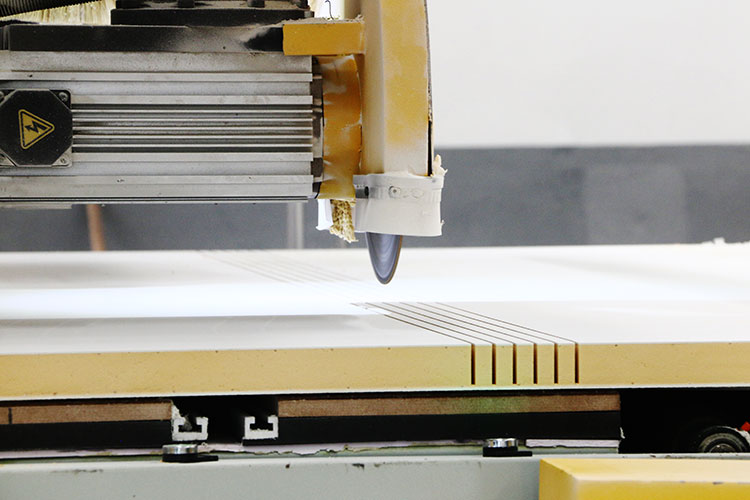

CNC Machining for Caravan Composite Panels

You receive not a rough semi-finished product, but a finely finished product. – In addition to customizing the thickness, width, length and color, we also provide a series of CNC machining treatments for RV composite panels: cutting, drilling, milling, and grinding. We use 5-axis CNC machines with high speed and precision, and the error is within 1mm.

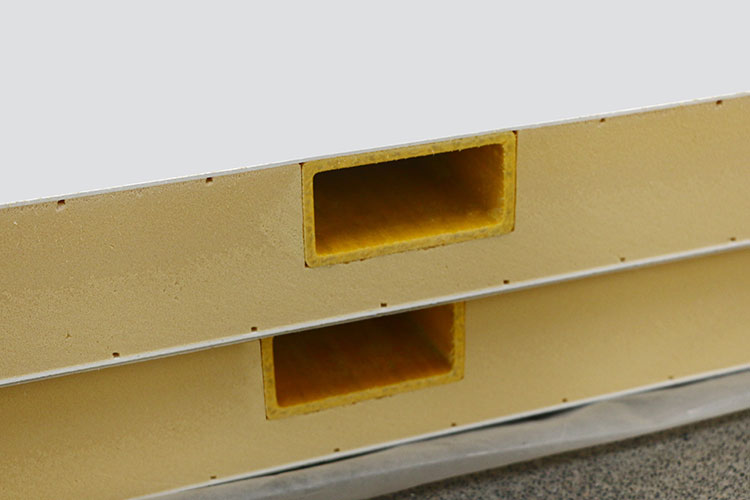

Embedded Reinforced Structural Materials

Embedded reinforced structural material. Various reinforcing materials such as aluminum tubes, steel tubes, GRP tubes, timbers, and various metal or plastic components can be used as the internal frame structure of the composite panel. In order to improve the performance of composite panels, we developed PVC composite materials with corrosion resistance and low thermal conductivity as purlins instead of timbers and aluminum tubes, which not only ensured the strength of composite boards for RVs, but also avoided the occurrence of cold and thermal bridge problems.