Composite bamboo and plywood, the design combines the lightweight, environmentally friendly and strength properties of bamboo with the stability and structural support properties of plywood.

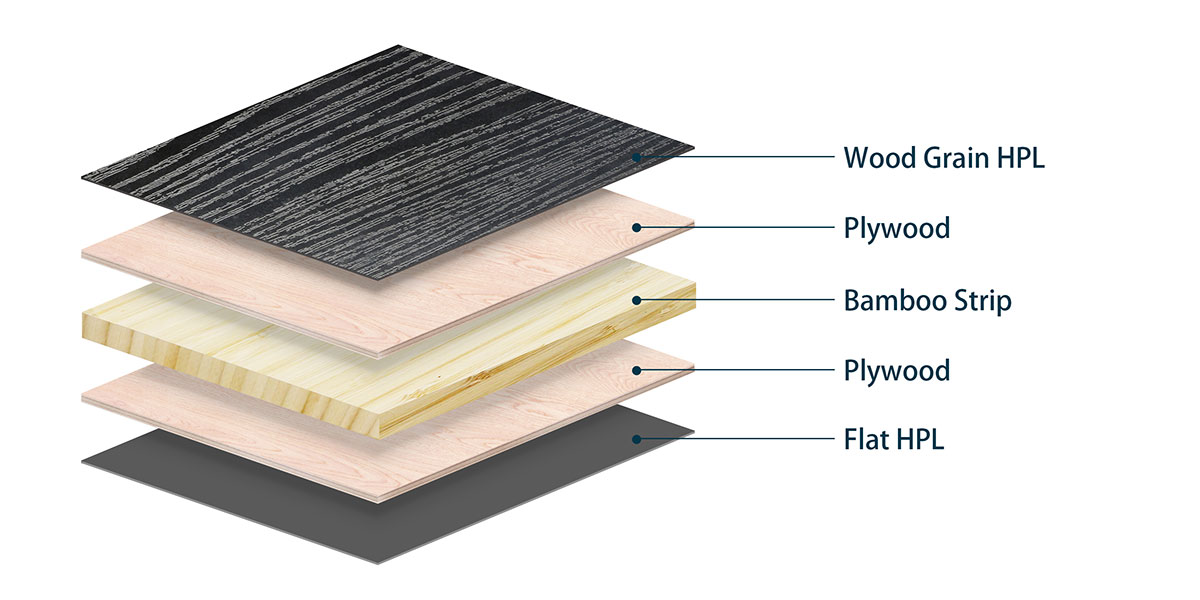

Structure of Bamboo Plywood Panel

- HPL Sheet: HPL is not only waterproof and wear-resistant, but its rich surface texture has good decorative and beautifying effects.

- Plywood: Plywood maintains the flatness of the panel and has high nail-holding properties.

- Bamboo Strip: Treated bamboo strips are layered together and glued under high temperature and pressure to form a strong board.

Advantages of Using Bamboo

- Environmental Protection: Bamboo is a renewable, fast-growing plant. Compared with traditional wood, the manufacturing of bamboo plywood puts less pressure on forest resources. It is an environmentally friendly and sustainable building material.

- Lightweight: Bamboo is relatively lightweight, which makes it an advantage when there is a need to lighten a structure or in lightweight construction projects.

- Strong and Durable: Bamboo has excellent strength and hardness. It is excellent in bending, tensile and compression resistance, making it a stable structural material.

- Shape Stability: Bamboo plywood is treated with high temperature and pressure during the manufacturing process, which makes it more stable and less likely to deform, crack or warp.

- Thermal Insulation Properties: Bamboo has good thermal insulation properties, making bamboo plywood perform well in some applications that require thermal insulation or insulation.

advantages of sandwich structure

- No Delamination: Using high-quality environmentally friendly glue, it can withstand the working temperature environment of -40~80℃. Due to its sandwich structure, even if the bamboo strip unit is loose in structure, it will not affect the overall performance.

- Higher Strength: The sandwich structure can effectively slow down the transfer of kinetic energy from the surface layer to the core material layer, while the toughness of the bamboo strips can effectively release impact force.

- The Surface Is Smoother: Plywood is added as an isolation layer, and then subjected to high temperature and high pressure, the surface is smoother and less likely to deform.

Basic Specifications

| Size | Max 2100×6000mm. |

| Thickness | 9.0~35mm |

| Corelayer | 100% bamboo |

| Plywood Layer | Particleboard, poplar, pine, composite wood, eucalyptus, birch, meranti, Okoume, other hardwoods. |

| Adhesives | Phenolic formaldehyde glue (PF, phenolic WBP glue, phenolic glue), melamine WBP glue (MUF, MF, melamine glue. |

Performance Parameters (Reference)

| Container Weight | ≥0.8g/cm3 |

| Water Content | ≥7% |

| Static Bending Strength (Vertical) | ≥900kgf/cm2 |

| Static Bending Strength (Horizontal) | ≥500kgf/cm2 |

| Impact Strength | ≤0.6kgf·m/cm2 |

| Flexural Strength of Bonding Layers | ≥20kgf/cm2 |

| Water Absorption (after 24h water-soaking) | ≤20% |

| Thickness expansion (after 24h water-soaking) | ≤6% |

| Wooden Screw Holding Force | ≥180kgf/cm2 |

Applications of Bamboo Plywood Panel

Bamboo plywood has a wide range of applications and is currently widely used in construction, packaging, shipbuilding, transportation, agriculture, etc.

- Furniture: Bamboo plywood can be used as tables, chairs, wardrobes and other furniture. It is also very profitable when building temporary mobile homes and temporary work sheds, and has won the favor of many people.

- Transportation: It can be used as flooring material for various carriages to replace hardwood floors.