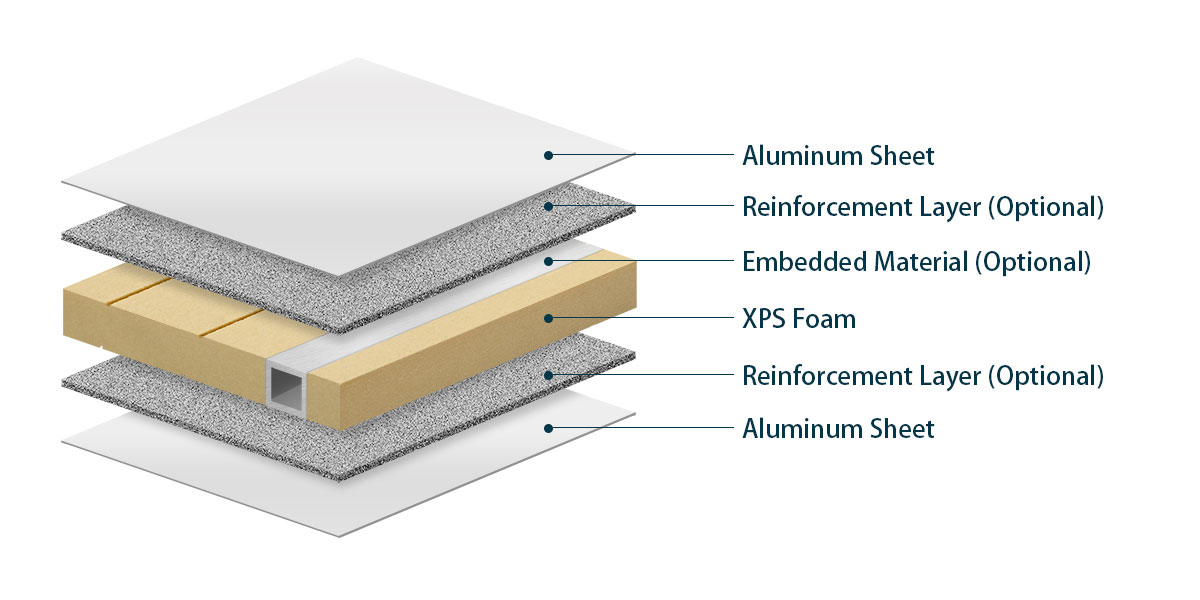

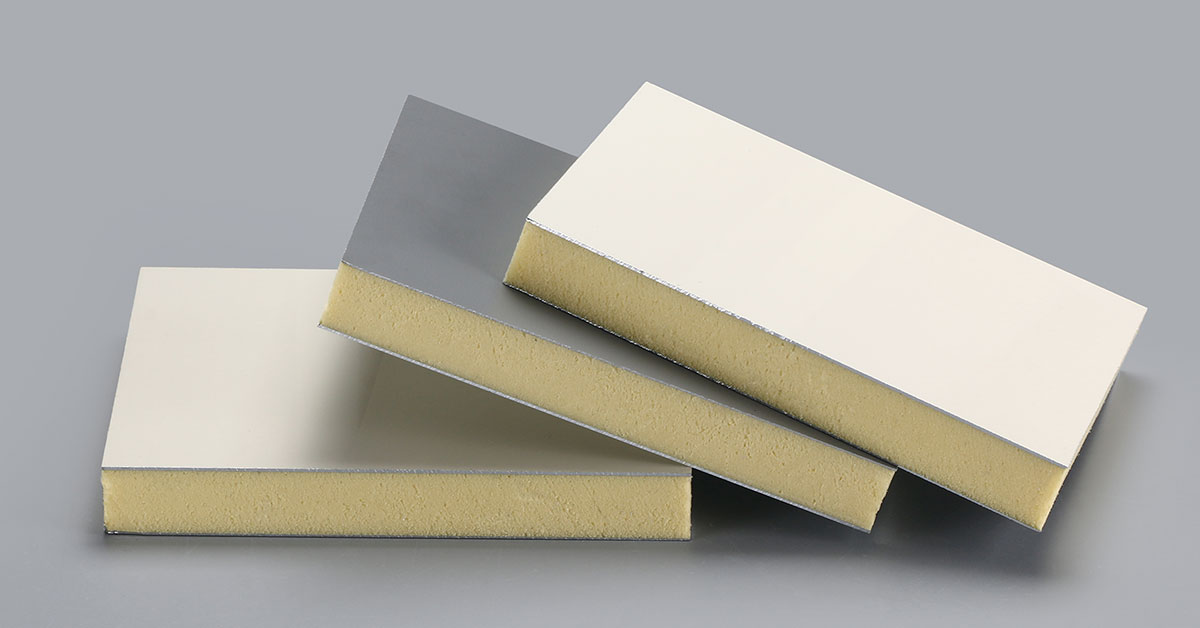

Aluminum XPS sandwich panels are composite materials typically used in construction and other applications where insulation and lightweight yet sturdy structural components are needed. The aluminum sheets and XPS foam together form a sandwich-like structure, where the XPS foam acts as an insulating layer between the two aluminum sheets. The panel is lightweight, structurally stable and has good thermal insulation properties.

Basic Structure

- Aluminum Sheets: The outer layers of the sandwich panel are made of aluminum sheets. Aluminum is used because of its lightweight nature, corrosion resistance, and strength.

- XPS (Extruded Polystyrene) Core: The core of the sandwich panel is made of XPS foam. XPS is a type of rigid, closed-cell foam insulation. It offers excellent thermal insulation properties and high compressive strength. XPS foam is moisture-resistant and provides a good balance of insulation and weight-bearing capabilities.

Basic Specifications

| Total Thickness | 10~120mm |

| Aluminum Sheet Thickness | 0.1~3.0mm |

| XPS Foam Density | 35~50kg/m³ |

| Width: | 800~2600mm |

| Length | ≤12m |

| Aluminum Grades | 1050, 1060, 1100, 1145, 1200, 1230, 1350, 2011, 2014, 2017, 2018, 2124, 2219, 2319, 3003, 3004, 3105, 5005, 5052, 5083, 5086, 6061, 6063 ,7075, 7050, 7049, 7100, 8006, 8111, 8079, etc. |

| Aluminum Surface Treatment | Sandblasting, polishing, glossy, embossed, matte, fluorocarbon coating, anodizing, etc. |

| Aluminum Surface Color | RAL color, or customized pattern. |

Application fields of aluminum XPS sandwich panels

- Buildings: These panels are commonly used on building exteriors, roofs and walls to provide insulation and structural support.

- Transportation: They are used to make lightweight components in the automotive, aerospace and marine industries, reducing overall vehicle weight and improving fuel efficiency.

- Industrial: These panels are suitable for industrial environments where lightweight insulating panels are required for a specific purpose.

- Cold Storage: Aluminum XPS sandwich panels are used in cold storage facilities to maintain a stable temperature and prevent heat transfer.

- Modular Construction: Due to their lightweight and insulating properties, they are used in the construction of prefabricated and modular buildings.

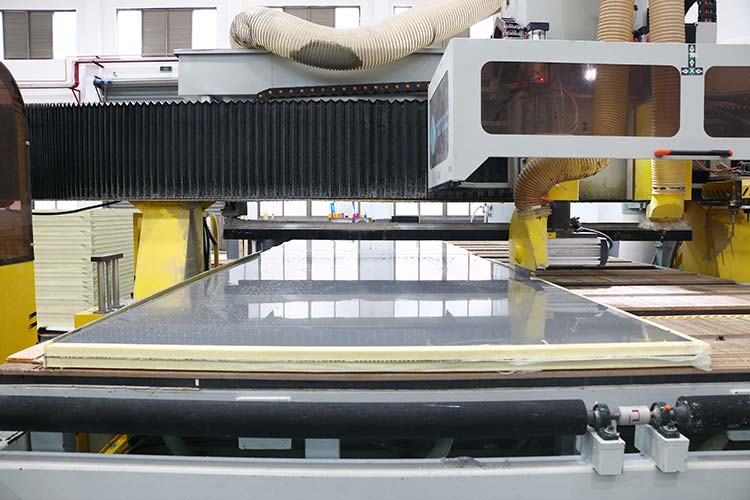

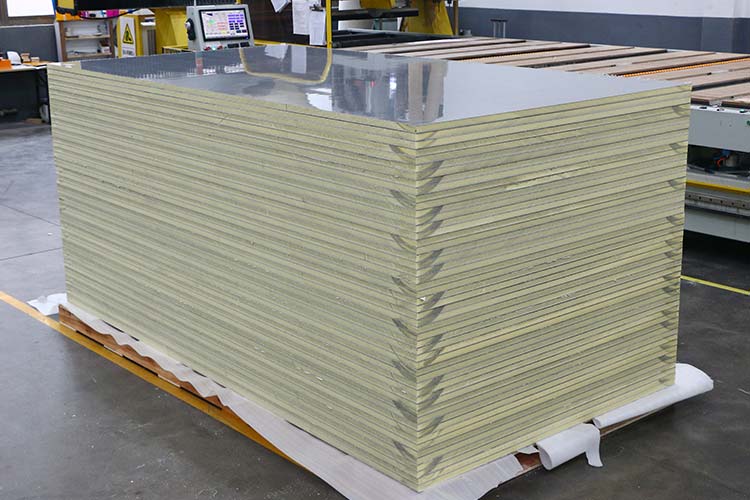

Expert in Aluminum Composite Panel Manufacturing

We select the highest quality raw materials and use the most advanced production equipment to produce high-performance aluminum composite panels.

Manufacturing Process of Aluminum Skin XPS Foam Sandwich Panels

Learn more about Aluminum Skin Foam Core Sandwich Panels