CNC Processing Line

•High Precision •High Speed •Customization

We provide high-precision CNC processing for various types of RVs, trucks, and building composite panels. Using CNC (Computer Numerical Control) machining can greatly improve the processing efficiency and precision of materials. We use advanced 5-axis simultaneous machining to meet various high-standard material processing needs.

Advantages of Our CNC Machining

High Speed

Achieve high-speed feeding, high-speed positioning, high-speed cutting, and be able to quickly switch tools.

High Precision

High-precision CNC programs ensure the accuracy of cutting paths and tool trajectories, and minimize processing errors. The five-axis synchronous design cooperates with precision cutting tools to ensure cutting accuracy.

High Specification

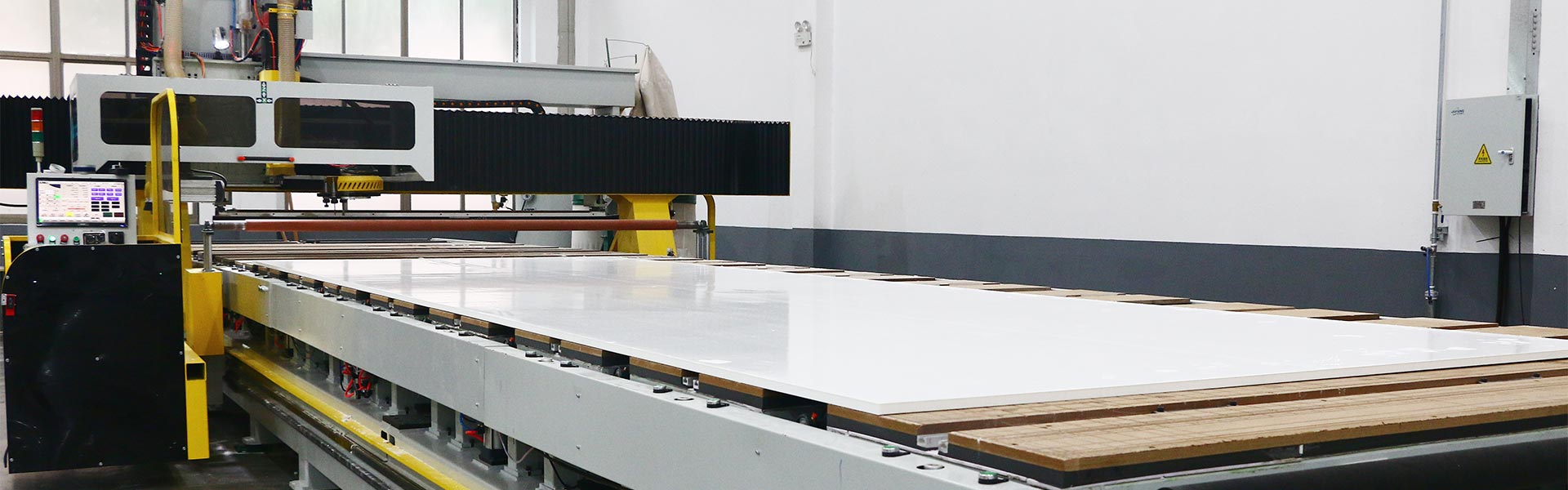

The 3.2m wide and 12m long operating platform can meet specific processing needs.

Able to Process a Variety of Materials

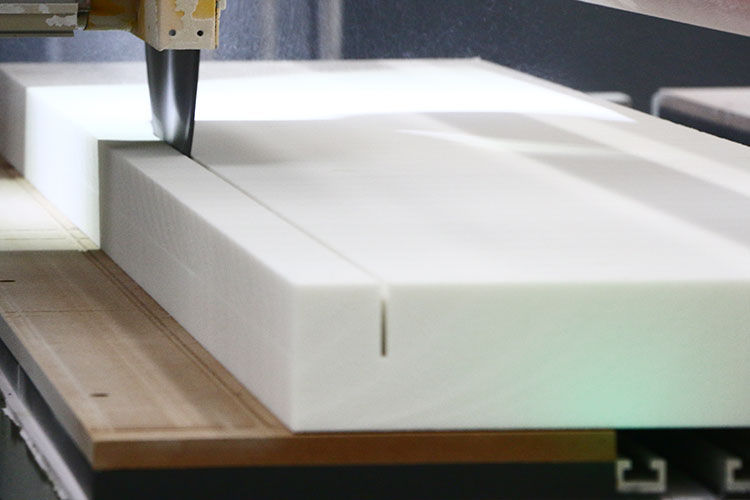

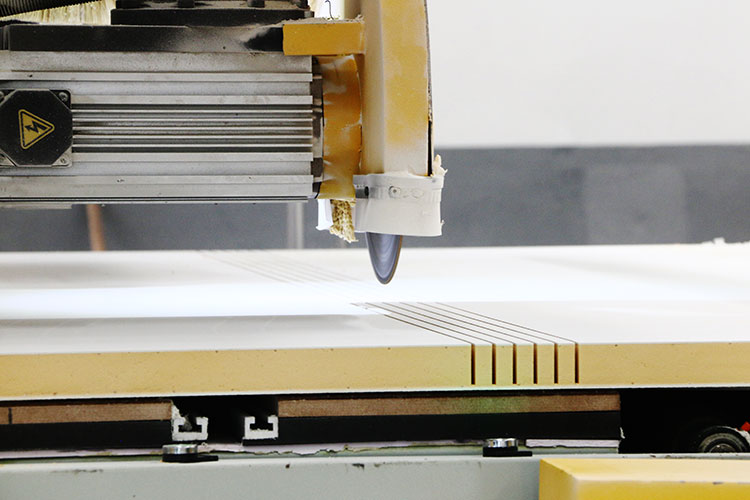

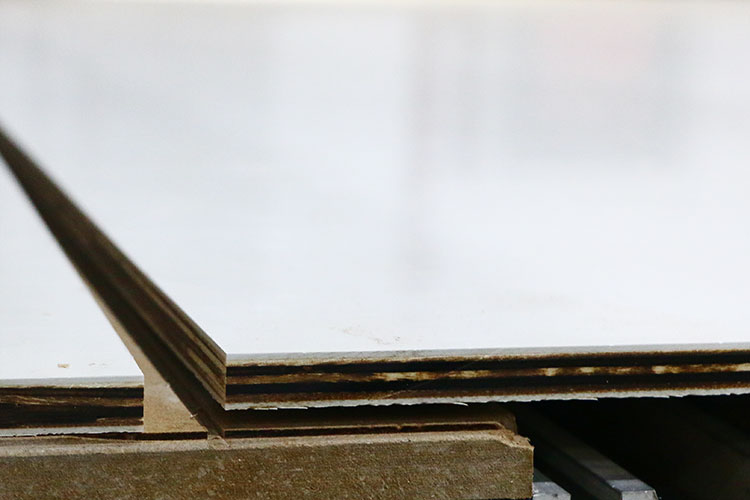

CNC can process a variety of sandwich panels, core materials, and internal embedded parts.

- Foam sandwich panels.

- Honeycomb sandwich panels.

- Plywwod sandwich panels.

- Foam board;

- Timbers;

- Aluminum profiles.

- Fiberglass profiles.

- Etc.

What processing can CNC machines complete?

- Cutting.

- Drilling.

- Grinding.

- Sculpture.

CNC Machining of Composite Panels for Trucks and RVs

When building box trucks and RVs, after the composite panels are produced, the shape needs to be trimmed and reprocessed. Mass production requires higher speed and precision, and fully automated CNC can meet such batch processing needs.