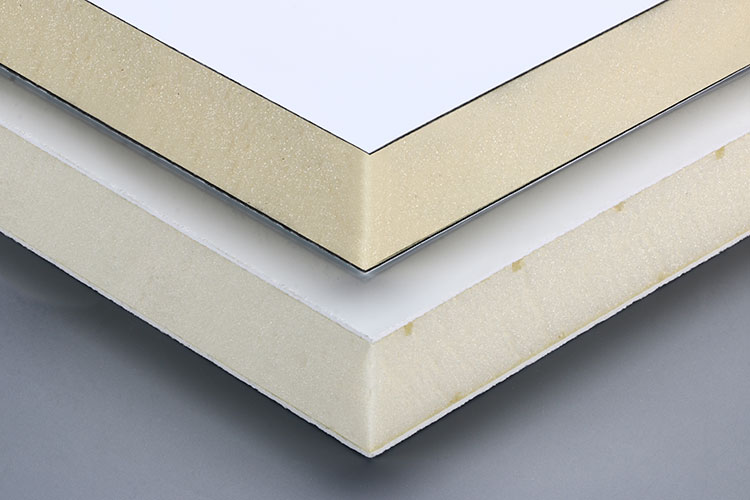

GRP foam sandwich panels are the most widely used fiberglass composite panels, which usually consist of two layers of GRP skin and a foam core (XPS/PET/PVC/PU, etc.) in the middle. This sandwich structure endows it with lightweight, heat insulation, high strength and other characteristics, and at the same time, the outer layer of FRP also endows it with excellent characteristics of waterproof and corrosion resistance.

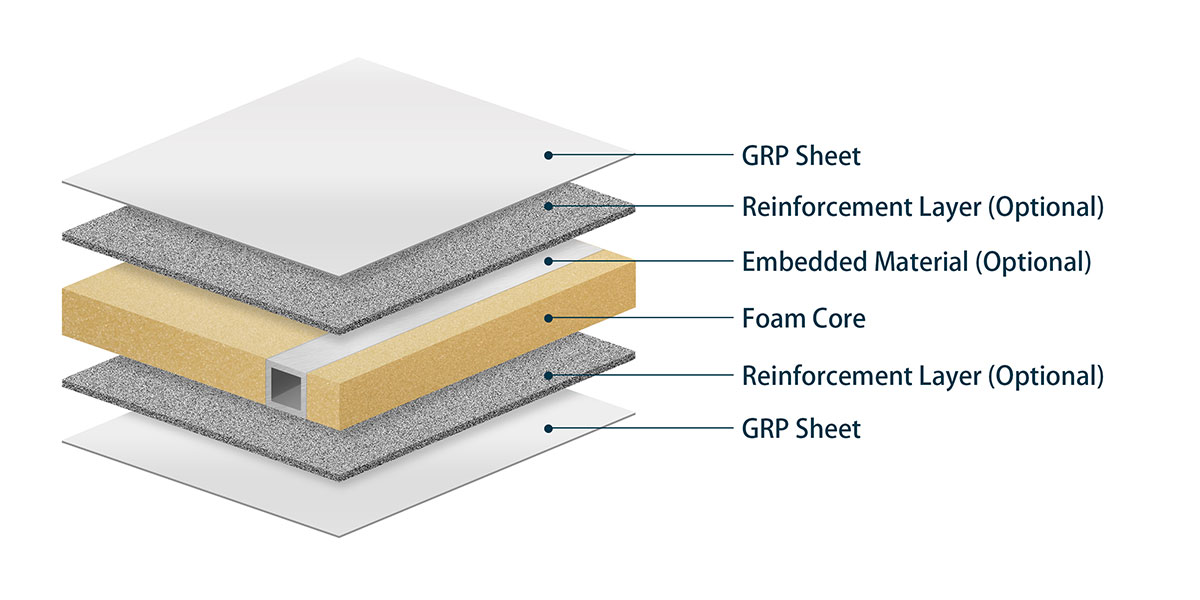

Structure Schematic

- Surface Layer: Flat GRP sheet. It imparts strength, hardness and durability to the sheet, allowing it to withstand the pressure and impact of the external environment.

- Foam Core: The foam core provides thermal insulation properties while also reducing the weight of the panel.

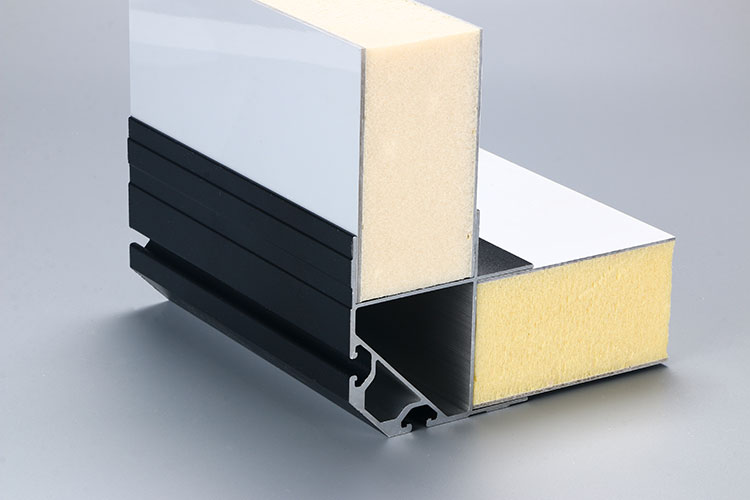

- Reinforcement Layer: Various materials can be selected as reinforcement layers (plywood, aluminum, felt, etc.). It increases the strength of the panel and also makes the surface of the panel more even.

- Embedded Materials: Embedding various reinforcing structural materials inside the composite panel can increase the strength of the panel.

Basic Specifications

- Skin Materials: GRP sheet, CFRT sheet.

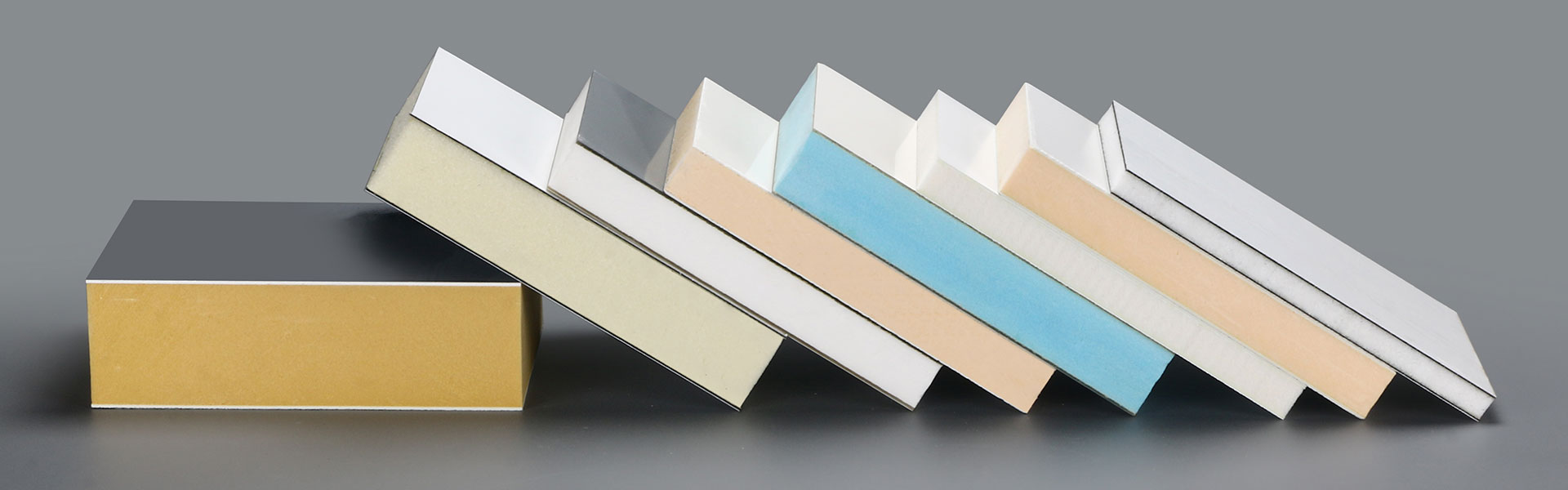

- Core Materials: XPS, PET, PVC, PU foam core.

- Performance Rreatment: anti-ultraviolet, flame retardant, antistatic.

- Length: ≤12m.

- Width: ≤3.2m.

- Total Thickness: customized.

- Process Options: Embedded reinforcement materials; CNC machining services.

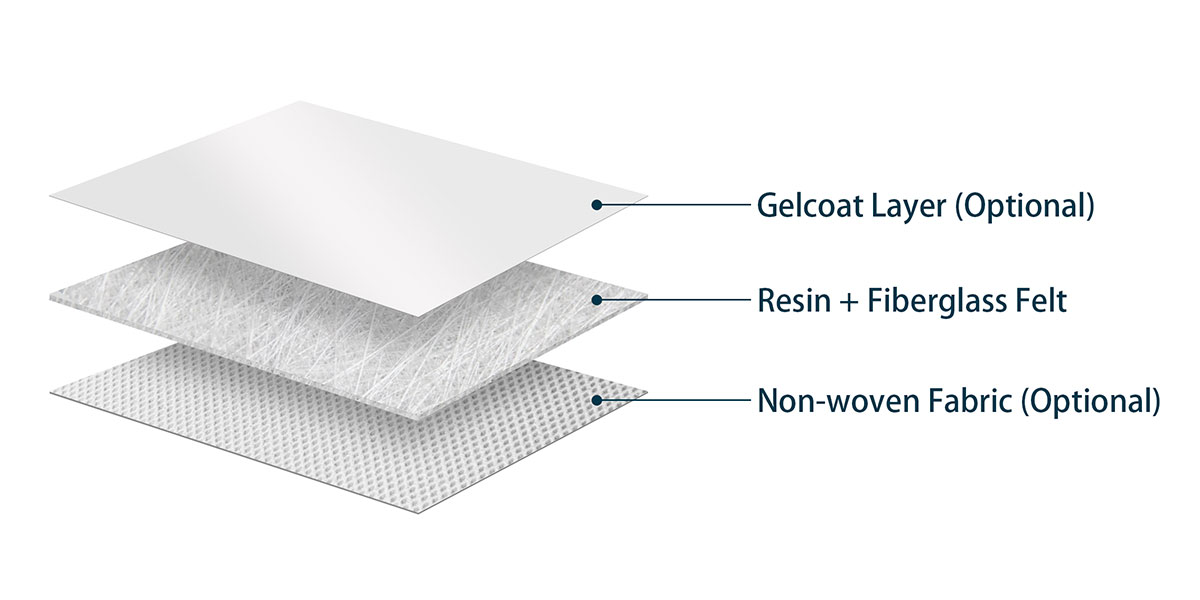

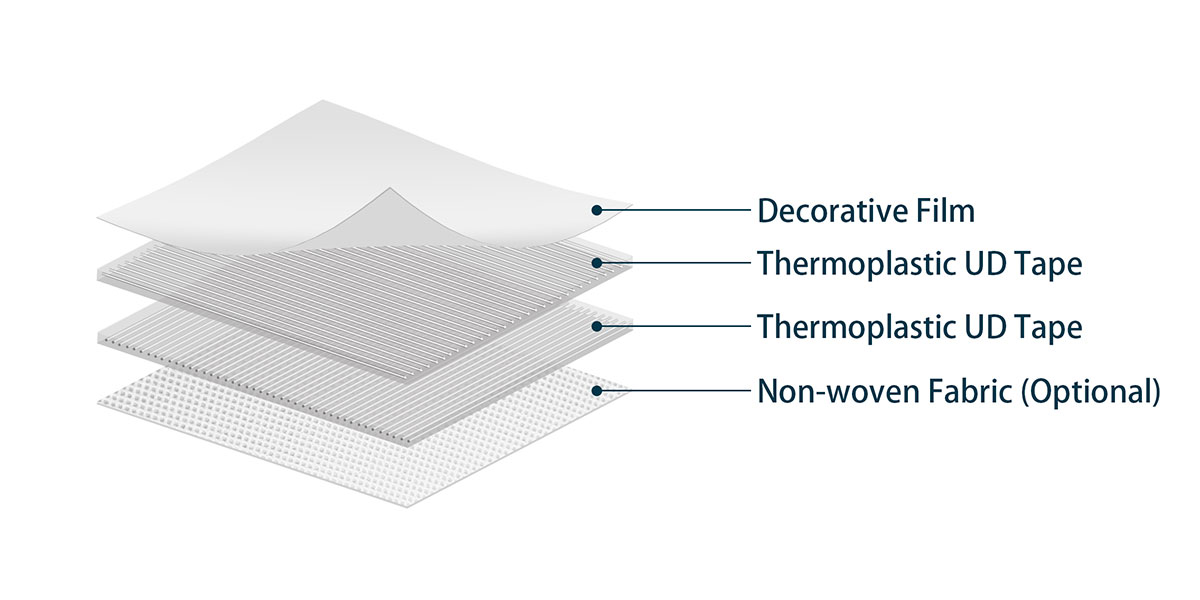

Selection of GRP Sheets

We offer two different systems of GRP sheets as skin materials for sandwich panels: fiberglass reinforced thermosetting – GRP sheet; Continuously fiberglass reinforced thermoplastic – CFRT sheet.

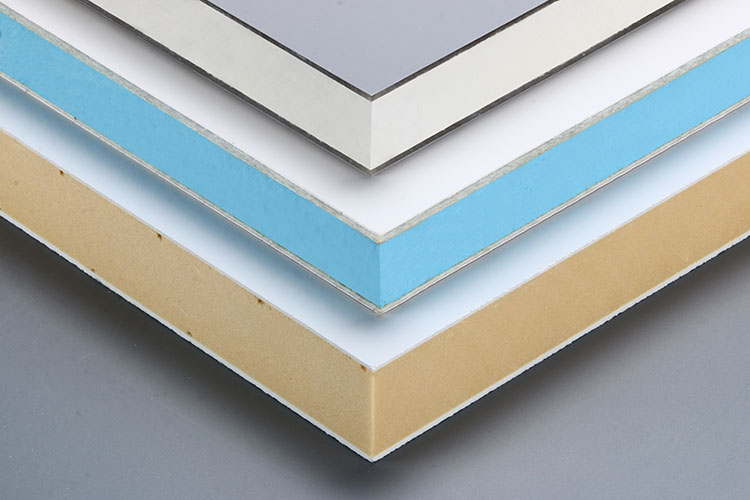

Types of Foam Cores

We use high-quality rigid closed-cell foams that provide good thermal insulation, shock-absorbing properties and also offer high strength and durability.

Processing Services

Quality Promise

Our GRP foam sandwich panels are all processed by one-piece composite panels. Our quality is reflected in:

- The surface of the panel is flat and smooth without unevenness.

- The foam core material is tightly bonded to the GRP sheet and can withstand high temperatures without delamination.

- The GRP composite panel has stable performance and long service life.

Applications of GRP Foam Sandwich Panels

GRP foam core sandwich panels are suitable for many industries and applications, and it is mainly used for thermal insulation, structural support and decoration.

- Wall panels, floors, roof panels and interior furniture panels for all types of travel trailers, C-type motorhomes.

- Wall panels and flooring for refrigerated and dry trucks.

- Mobile toilets, mobile houses, mobile shelters, sentry boxes, etc.

- The deck of the ship, and the partition material of the internal building.