XPS sandwich panels are composite materials with XPS (extruded polystyrene) as the core material, which is a structural type with stable performance. The panels supplied by T-Panels are vacuum laminated: the skin material and the XPS core are bonded together using an adhesive through a laminator, during which the air between the core and the skin is extracted.

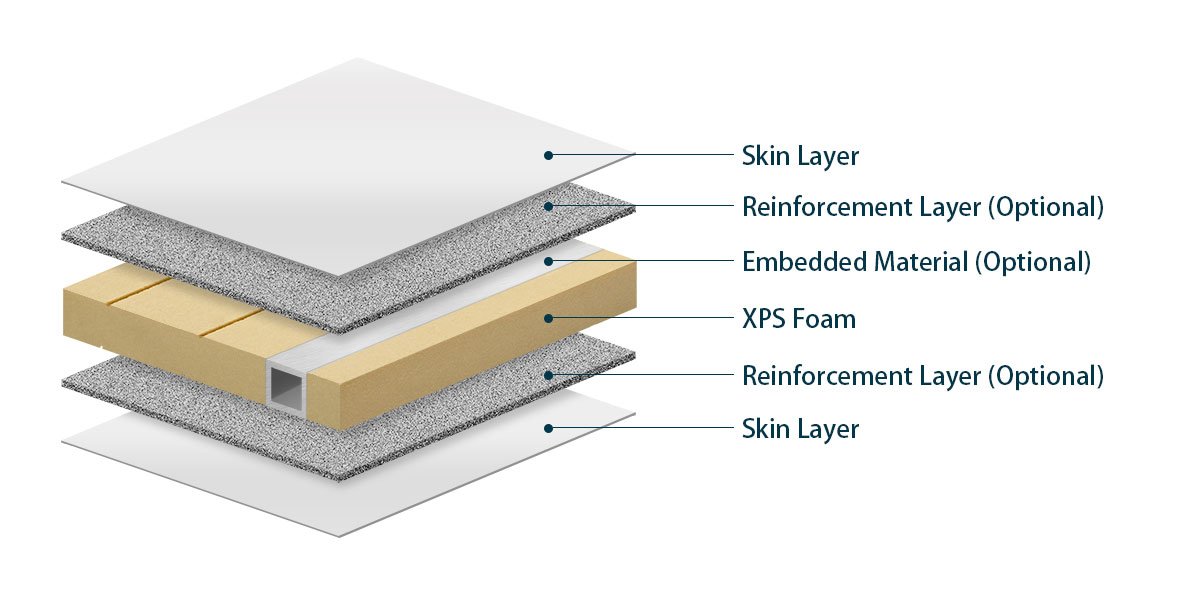

Structure Schematic

- Surface Layer: GRP, CFRT, aluminum, stainless steel, pre-coated galvanized steel, PVC, etc. can be selected as skin materials. They can be tightly bonded to the core material.

- XPS Foam Core: The XPS foam core provides thermal insulation properties while also reducing the weight of the panel.

- Reinforcement Layer: It increases the strength of the panel and also makes the surface of the panel more even.

- Embedded Materials: Embedding various reinforcing structural materials inside the composite panel can increase the strength of the panel.

Specifications

| Skin Materials | GRP sheet, CFRT sheet, Aluminum sheet, galvanized steel sheet, stainless steel sheet, PVC board, HPL plywood, etc. |

| Core Materials | XPS foam core.(Density: 35~50kg/m³) |

| Performance Treatment | Anti-ultraviolet, flame retardant, antistatic. |

| Length | ≤12m. |

| Width | ≤3.2m |

| Total Thickness | 10~120mm or Customized. |

| Process Options | Embedded reinforcement materials; CNC machining. |

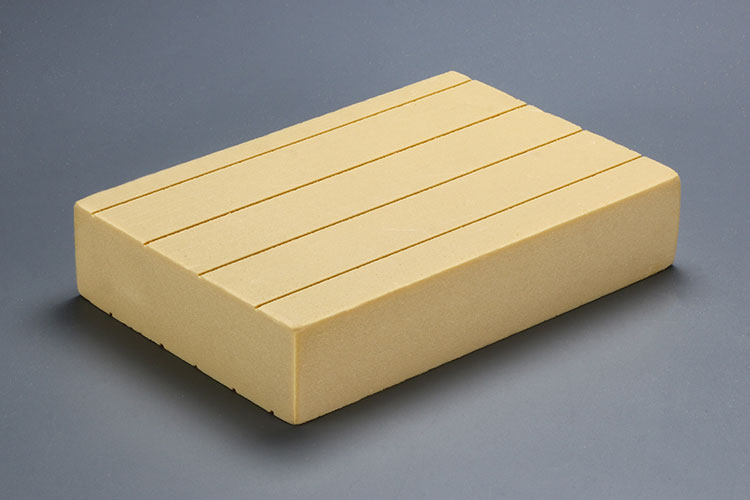

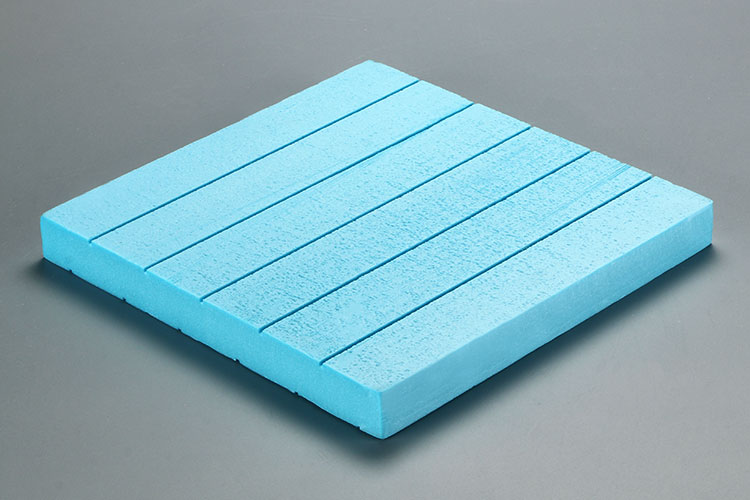

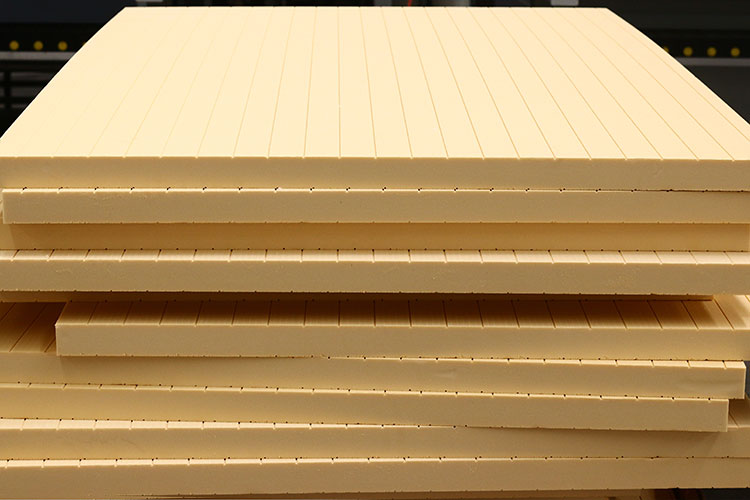

XPS Foam Core

XPS foam is a kind of closed-cell foam with excellent properties such as lightweight, compression resistance, heat insulation, waterproof, corrosion resistance, etc., so it is often used in buildings and industrial fields, because of its ultra-low thermal conductivity it is used to make thermal insulation material. Currently, XPS foam boards on the market generally come in yellow, white, blue, green, red, etc. Different colors of foam boards are due to the different color masterbatches added.

Skin Materials of XPS Sandwich Panels

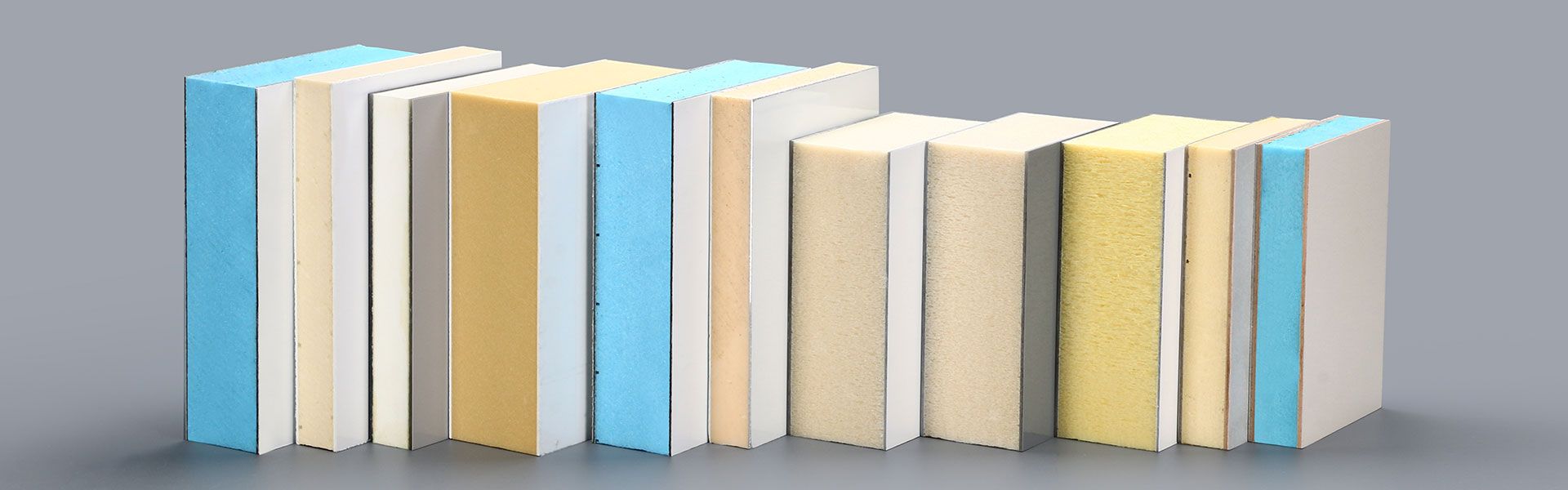

XPS foam is compatible with many different material systems via adhesives and maintains this stable performance over the long term. Therefore, there are many choices for XPS sandwich panel skin materials.

These Materials Include:

- GRP Sheet.

- CFRT Sheet (Continuous fiber reinforced thermoplastic).

- PVC Sheet.

- Aluminum Sheet.

- Galvanized Steel Sheet.

- Stainless Steel Sheet.

- HPL Plywood.

Processing of XPS Sandwich Panels

Premium Materials

Using high-quality raw materials, the foam board has pure color, uniform texture and stable performance.

Extra Large Size

Using a one-piece composite panel lamination process, the length of the panel can reach 12m and the width can reach 3.2m.

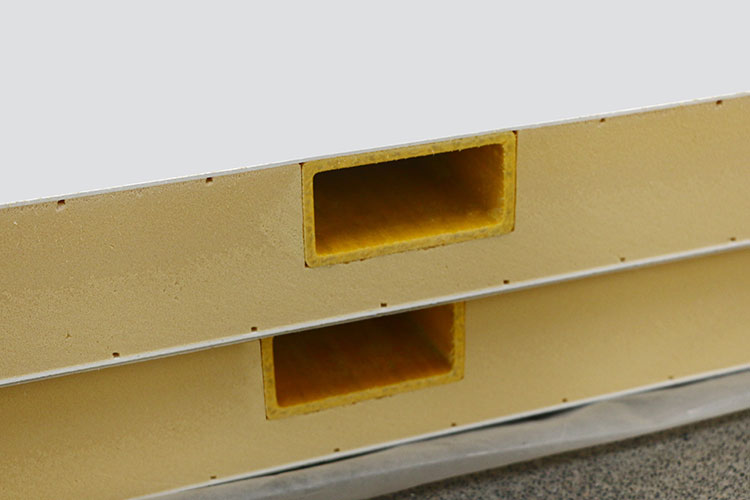

Internal Embedded Materials

Aluminum profiles, steel profiles, fiberglass profiles, timbers, and other materials can be embedded inside the sandwich panels.

CNC Machining

Cutting, drilling, and cutting of XPS sandwich panels by 5-axis synchronous CNC machines.

Applications of XPS Sandwich Panels

XPS sandwich panels combine lightweight, waterproof, thermal insulation and other properties. It is widely used in various buildings, vehicles, boxes and indoors.

RV Bodies

Floor caravan, C-class RV, travel trailer, teardrop, mobile RV, etc. It is mainly used in the floor, wall panel and roof of RV.

Truck Bodies

Wall panels, roofs, and floors for refrigerated trucks, dry goods trucks.

Yachts

Decks, bulkheads, and ceilings of yachts.

Building Interior

Door panels, bed panels, partitions, ceilings.

Other Applications: billboards, cold storage, container houses, mobile toilets, thermal insulation rooms, etc.