PET sandwich panels are a new type of environmentally friendly composite panel that can provide higher strength and stiffness while maintaining a relatively lightweight. PET (Polyethylene Terephthalate) foam is a rigid closed-cell foam that does not absorb water. Compared with other foam materials, it has higher compressive strength and hardness, so it has better durability.

We customize PET foam sandwich panels in various specifications: different widths, thicknesses, lengths, and skins. We have efficient and precise production lines and implement strict quality standards. This advantage has enabled us to win praise from many customers around the world.

Specifications of PET Sandwich Panels

- Skin Materials: GRP sheet, CFRT sheet, Aluminum sheet, galvanized steel sheet, stainless steel sheet, plywood, PVC board, HPL, etc.

- Core Materials: PET foam core.(Density: 80~300kg/m³)

- Performance Rreatment: Anti-ultraviolet, flame retardant, antistatic.

- Length: ≤12m.

- Width: ≤3.2m.

- Total Thickness: 10~120mm or Customized.

- Process Options: Embedded reinforcement materials; CNC machining services.

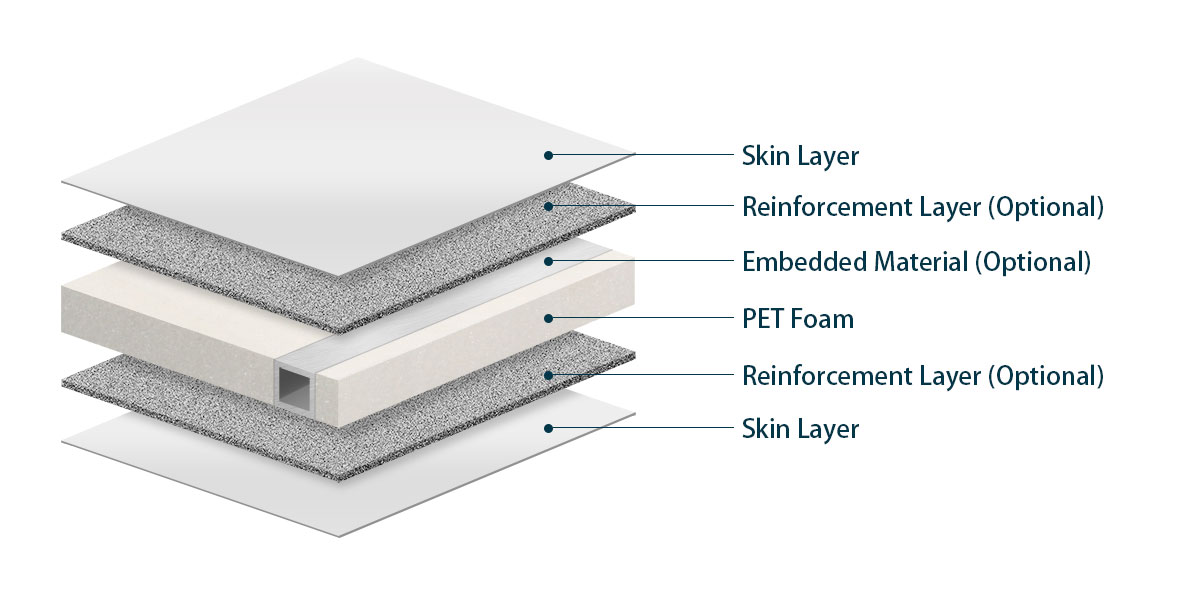

Structure Diagram of PET Sandwich Panels

- Surface Layer: PET foam can be tightly bonded with many material systems through glue, and maintain long-term performance stability, such as GRP, CFRT (continuous glass fiber reinforced thermoplastic), aluminum, stainless steel, GI, GL, plywood, etc.

- Foam Core: PET foam provides stable structural support.

- Reinforcement Layer: It increases the strength of the panel and also makes the surface of the panel more even.

Advantages of PET Foam Sandwich Panels

- High Strength

The strength of PET foam is higher, and it is usually thinner than other boards, which reduces the weight relatively. - High-Temperature Resistance

PET foam board can withstand a temperature of about 150°C for a short time during processing, and can withstand a temperature of about 100°C for a long time during its service life. - Low Water Absorption

PET foam basically does not absorb water, which allows it to still maintain good performance in some high humidity environments. - Recyclable

PET foam can be completely recycled and reused, which greatly protects the environment. - Easy to Cut

PET foam generally has a relatively high shear modulus, which allows it to be cut without deformation. - Low Cost

Because of the higher hardness of PET foam, usually PET sandwich panels do not need to pre-embed reinforcement materials, so it is more economical.

Applications

- Building Materials

PET sandwich panels are often used in walls, floors, door panels, ceilings, partitions and other parts inside buildings. - Box Truck Bodies

PET sandwich panels are widely used in dry goods truck boxes and brackets in van workshops. - RV Composite Panels

RV floors, ceilings, wall panels, internal partitions, bed panels, door panels, etc. - Yachts

Decks and partitions of yachts. - Transportation

Floors and partitions on subways, buses, high-speed rails, and airplanes. - Advertising Displays

Display boards, signs and billboards, etc.