Product Specifications

- Total Thickness: 28.0mm. (Customized: 10~120mm)

- Length: ≤12m.

- Width: ≤2.8m.

- Top Facing: 1.0 mm matte CFRT sheet. (Customized: 0.7~2.0mm)

- Core Layer: 150kg/m³ Recycled PET foam. (Customized: 60~300kg/m³)

- Bottom Facing: 1.0 mm matte CFRT sheet. (Customized: 0.7~2.0mm)

- Area Weight: 5.0kg/m².

Description

CFRT PET sandwich panels are sandwich structure panel that combines continuous fiber reinforced thermoplastic (CFRT) and polyester (PET) foam core.

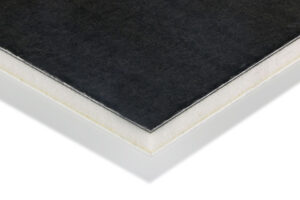

Schematic Diagram

Recycled PET Foam

Recycled PET foam not only meets the needs of various applications in terms of performance, but also has significant advantages in environmental protection. It is an ideal material with both economic and environmental benefits.

- Reduce plastic pollution: Using recycled PET materials to make foam can help reduce environmental pollution from plastic waste and alleviate ecological problems caused by plastic waste.

- Reduced carbon emissions: The process of making renewable PET foam significantly reduces carbon emissions compared to the production of virgin plastics, helping to mitigate climate change.

CFRT Sheets

CFRT (Continuous Fiber Reinforced Thermoplastic) sheet is a composite material that combines the advantages of continuous fibers and thermoplastic resin to provide excellent strength, stiffness and durability. More

Product Performances

- Lightweight.

- Structural strength.

- Impact resistance.

- preservative.

- Water resistance.

- Environmental protection.

Application Areas

It is widely used on floors, roofs, wall panels, partitions of buildings, RVs, and trucks.

Learn more about CFRT PET Sandwich Panels.