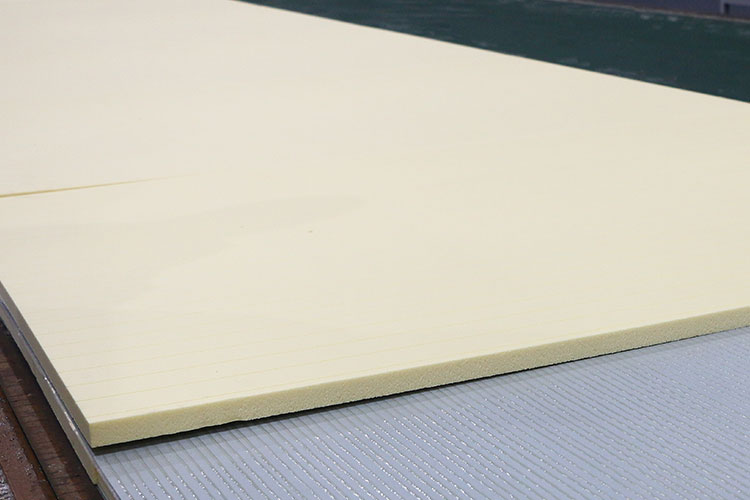

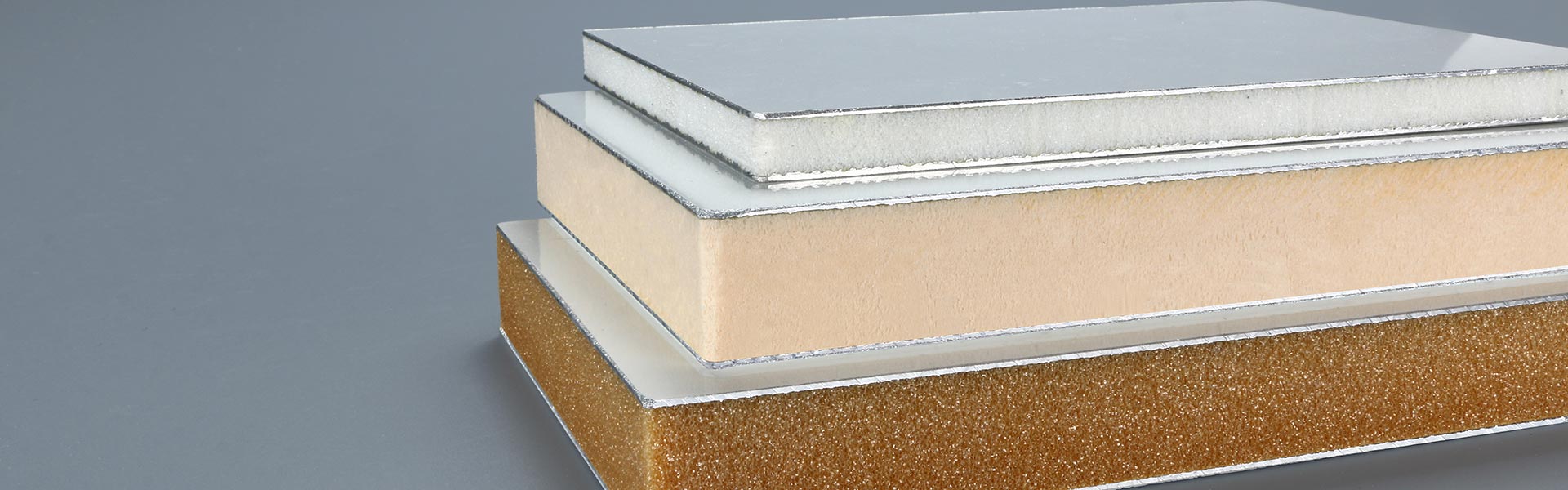

Aluminum facing foam sandwich panels are a common lightweight composite panel in daily life. It uses aluminum sheets as the surface skin and foam board as the core material. It has the advantages of waterproof, corrosion resistance, thermal insulation, gorgeous appearance, etc., and is used as various heat-insulating box panels or decorative wall panels.

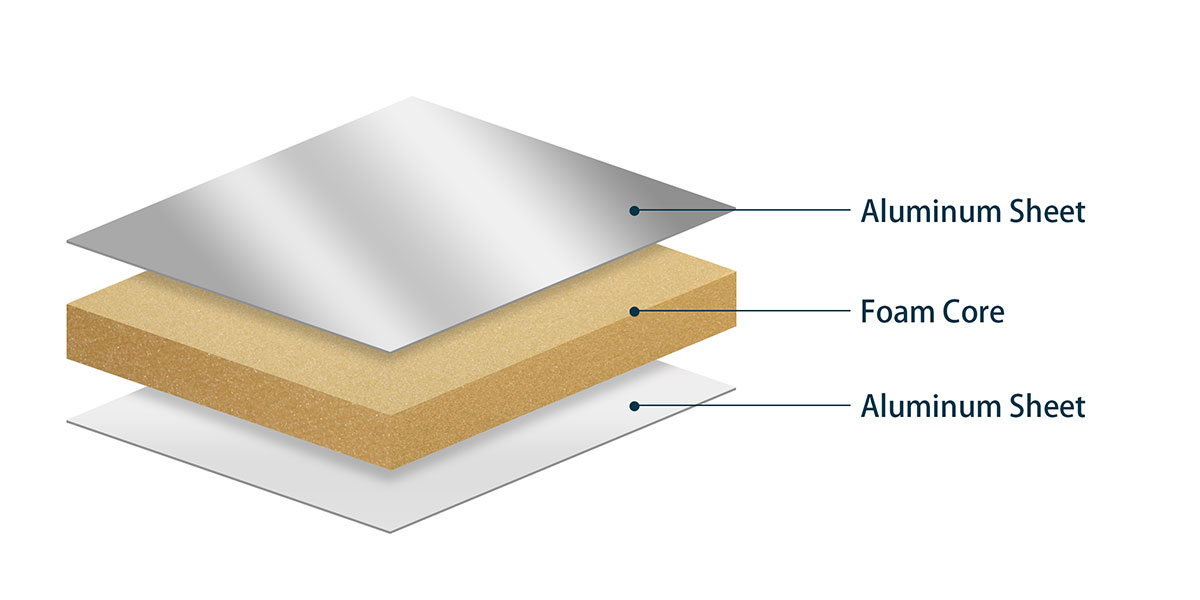

Structure Schematic

- Aluminum Facing

It provides the appearance, durability and corrosion resistance of the sandwich panel. It can also have different surface treatments such as painting, anodizing or coating to enhance its aesthetics and protective properties. - Foam Core

Common materials include XPS, PU, PET, PVC, etc. The foam core has lightweight, thermally insulating and shock-absorbing properties, which help to improve the insulating properties of the sandwich panel and reduce the overall weight.

Basic Specifications

| Total Thickness | 10~120mm. |

| Aluminum Sheet thickness | 0.1~3.0mm. |

| Core Material | XPS(Extruded Polystyrene) foam; PET(Polyethylene terephthalate) foam; PU(Polyurethane) foam; PMI(Polymethacrylimide)foam; PVC(Polyvinyl Chloride) foam, etc. |

| Width | 800~2600mm |

| Length | ≤12m. |

| Aluminum Grades | 1050, 1060, 1100, 1145, 1200, 1230, 1350, 2011, 2014, 2017, 2018, 2124, 2219, 2319, 3003, 3004, 3105, 5005, 5052, 5083, 5086, 6061, 6063 ,7075, 7050, 7049, 710 0, 8006, 8111, 8079, etc. |

| Aluminum Surface Treatment | Sandblasting, polishing, glossy, matte, embossed, fluorocarbon coating, anodizing, etc. |

| Aluminum Surface Color | RAL color, or customized pattern. |

Surface Treatment

Application Fields

- Refrigeration Equipment

Due to its insulating properties, this sandwich panel is suitable for the manufacture of cold rooms, refrigerated vehicles. - Buildings

This sandwich panel is widely used in building exterior walls and roofs. It provides weather resistance, thermal insulation and aesthetics. - Interior Decoration

Aluminum facing foam sandwich panels can be used for interior partitions, ceiling, and wall decoration. Its aluminum finish layer can be customized in color and texture according to design needs. - Transportations

Aluminum facing foam sandwich panels are widely used in the interior decoration of trains, buses, ships and aircrafts. It is used in the manufacture of interior siding, seating and insulation.

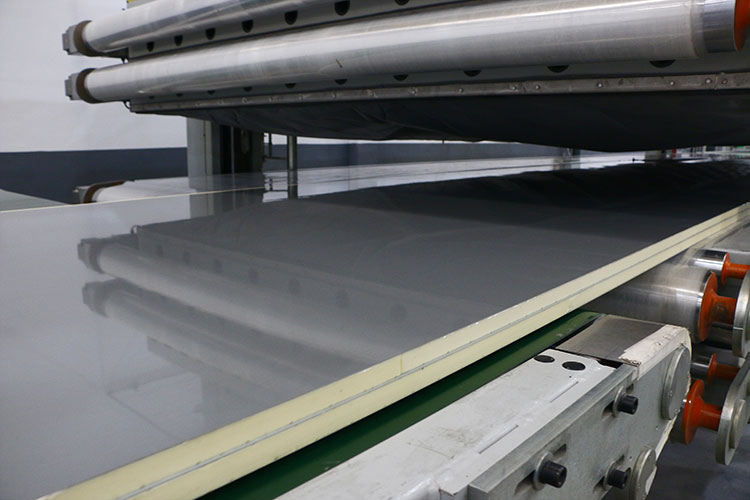

Custom Aluminum Facing Foam Sandwich Panels

We are a professional aluminum facing composite panel manufacturer and we provide customers with customized products. We ensure the most reliable products by using high-quality raw materials and state-of-the-art production equipment.