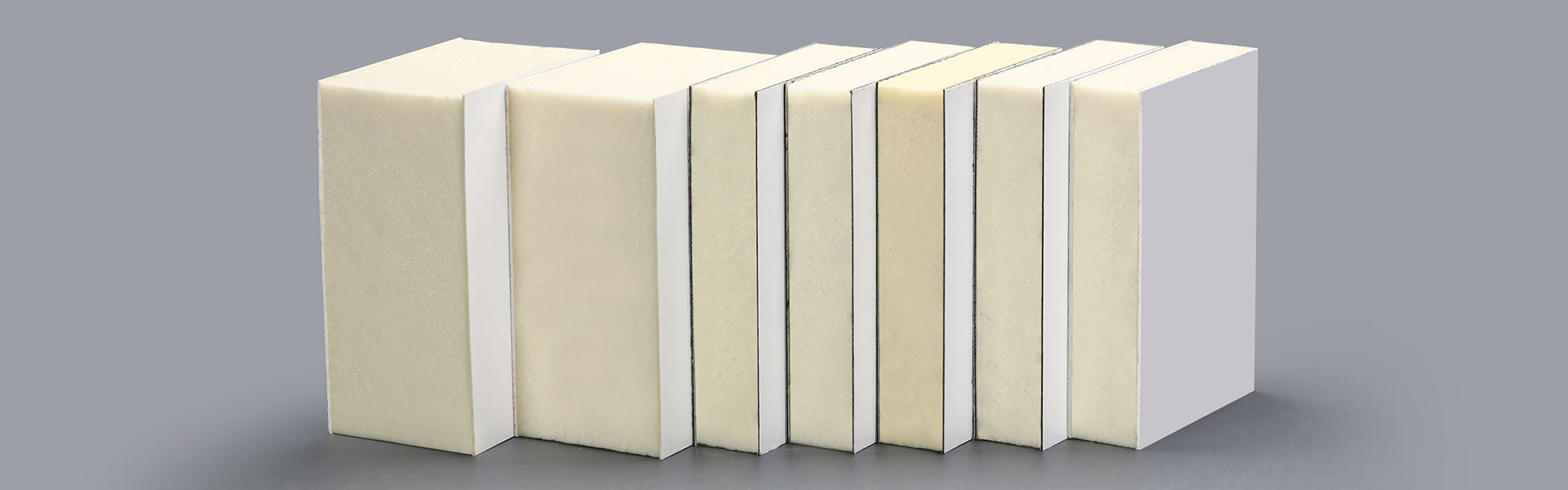

The PU sandwich panel is a sandwich structural panel with polyurethane foam as the core material and covered with skin materials on both sides. The PU sandwich panel supplied by T-Panels is a glued composite panel produced using a laminator.

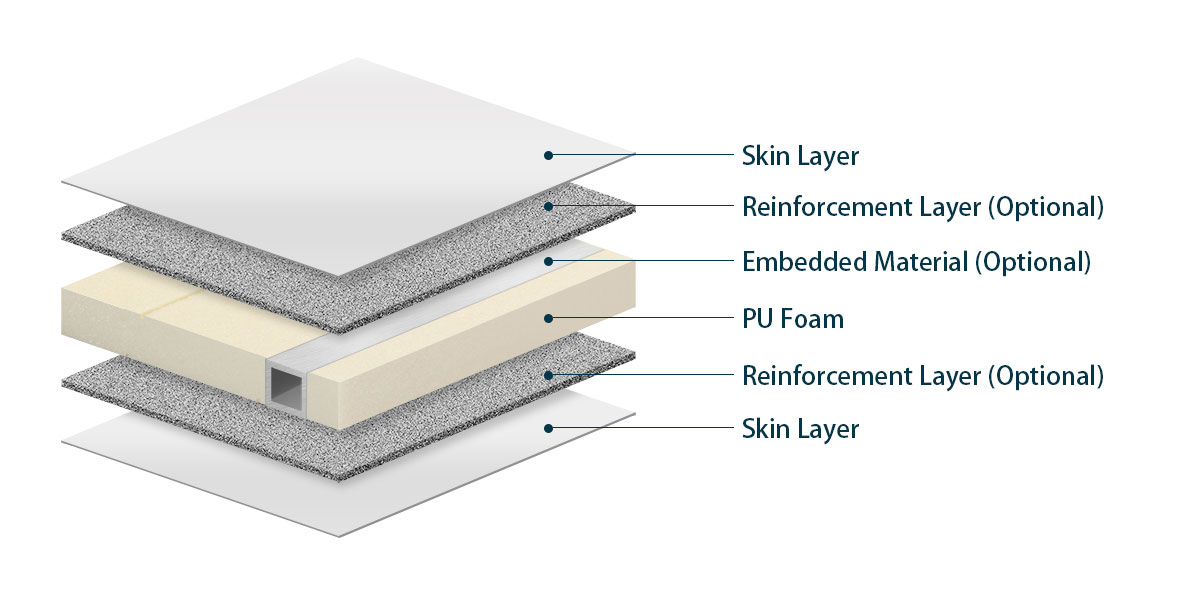

Basic Structure of PU Sandwich Panel

- Surface Layer: GRP, CFRT, aluminum, stainless steel, plywood, pre-painted galvanized steel, PVC board, etc.

- PU Foam Core: The PU foam core provides thermal insulation properties.

- Reinforcement Layer: It increases the strength of the panel and also makes the surface of the panel more even.

- Embedded Material: Optional embedded materials include aluminum pipe, steel pipe, timbers, GRP pipe, T-shaped components, etc. It increases the strength of the panel and also makes the surface of the panel more even.

Specifications

- Skin Materials: GRP sheet, CFRT sheet, Aluminum sheet, galvanized steel sheet, stainless steel sheet, plywood, PVC board, etc.

- Core Materials: PU foam core.(Density: 45~80kg/m³)

- Performance Rreatment: anti-ultraviolet, flame retardant, antistatic.

- Length: ≤12m.

- Width: ≤3.2m.

- Total Thickness: 10~120mm or Customized.

- Process Options: Embedded reinforcement materials; CNC machining services.

Its Advantages are Reflected in:

- Excellent Thermal Insulation Performance

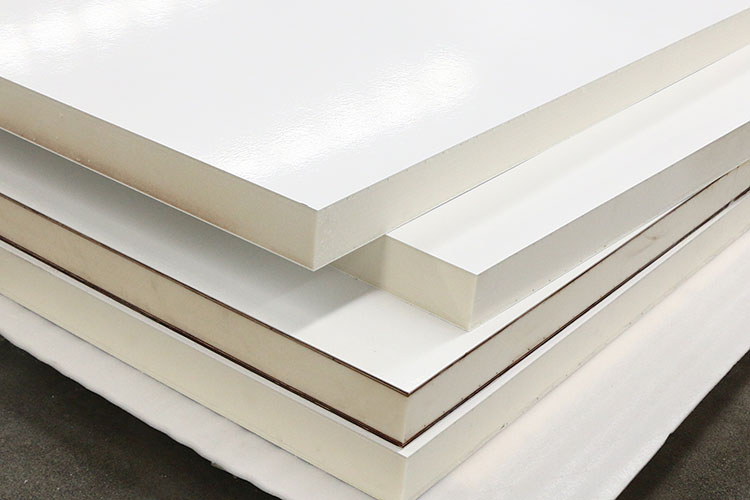

We use closed-cell rigid polyurethane foam, which has extremely low thermal conductivity and therefore has excellent thermal insulation performance. - Lightweight Performance

The density of polyurethane foam is low, and its lightweight is not only easy to handle and install, but also effectively reduces the load of the carrier. - Strength and Rigidity

The outer covering material of PU sandwich panels is usually GRP, metal or other hard materials, which endows the sandwich panels with higher strength and rigidity.

PU Foam Core

The PU foam used as the core material is a hard closed-cell structure material, and its closed-cell structure endows it with ultra-low thermal conductivity, so it is one of the most commonly used thermal insulation materials.

CNC Machining for PU Sandwich Panels

PU sandwich panels can be CNC machined into various shapes and sizes. We use a 12-meter 5-axis synchronous high-precision CNC machine tool, which can not only process large-size panels but also minimize errors.

Applications

Laminated PU sandwich panels are widely used in many fields. Due to its superior heat insulation and structural stability, it has been applied in the following fields:

- Refrigerated Truck: PU sandwich panels can provide good thermal insulation effects for refrigerated trucks.

- Cold Room: The PU sandwich panel with metal skin can provide stable structural support and thermal insulation effect for the cold room.

- Modular Building: PU sandwich panels are often used in walls, roofs and floors of buildings, such as farms and cultivation rooms.