CFRT Sandwich Panels

Lightweight, High Strength, Corrosion Resistant

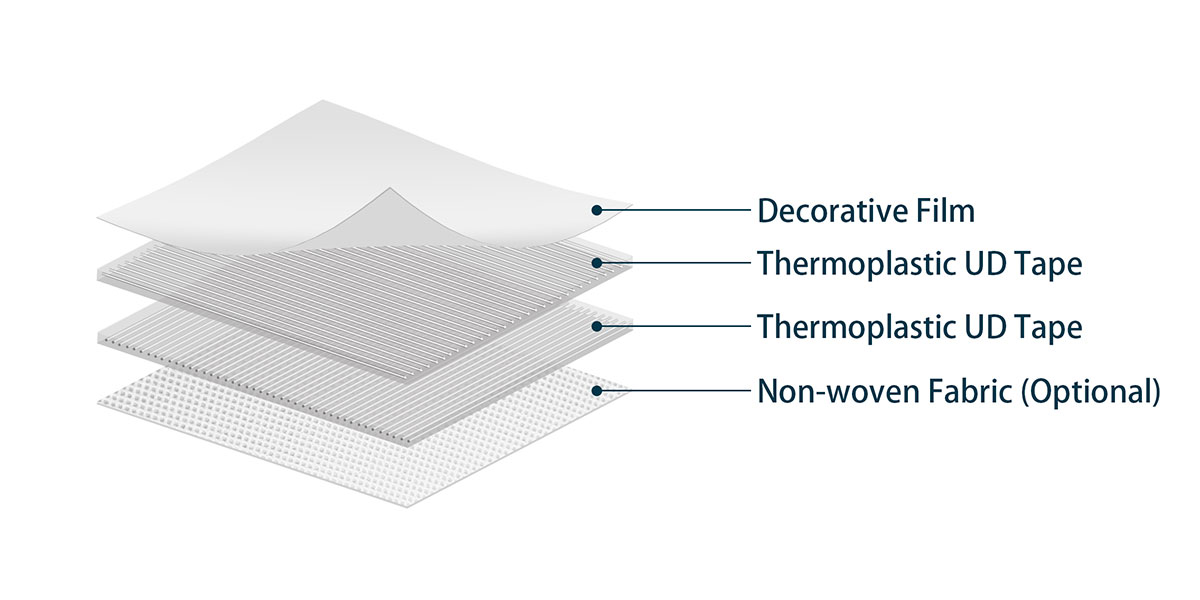

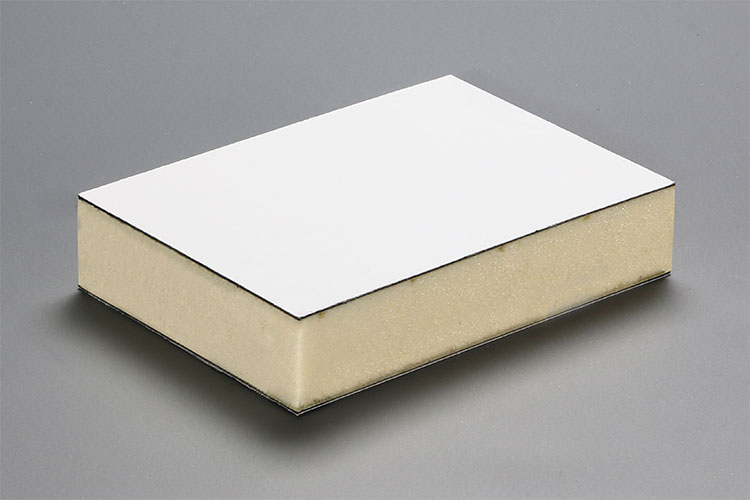

The outer layer of CFRT sandwich panels uses continuous fiber thermoplastic reinforcement technology (usually fiberglass), and the internal filling material is usually foam or honeycomb. Lightweight and high strength are the most important properties, making thermoplastic sandwich panels one of the first materials to achieve lightweighting in many products.

Basic specifications

- Skin:

Resin Types: Polypropylene (PP), polyethylene (PE), nylon (PA), polyphenylene sulfide (PPS), etc;

Layers of UD tape: 2~9 layers, the number of layers can be customized;

Thickness: 0. 4~10mm.

- Core Material:

XPS (Extruded Polystyrene) foam;

PET (Polyethylene terephthalate) foam;

PU (polyurethane_) foam;

PVC (polyvinyl chloride) foam;

PP (polypropylene) honeycomb;

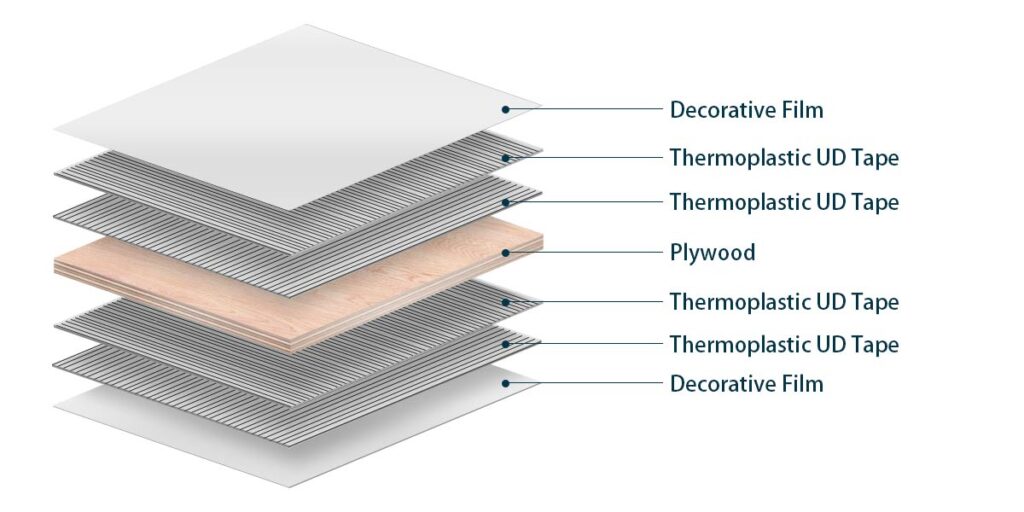

Plywood (poplar, birch, pine, eucalyptus, oak, etc.) etc.

What is CFRT?

The continuous fiberglass thermoplastic composite sheet (CFRT) is made of double-layer or multi-layer thermoplastic unidirectional prepreg tapes at an angle of 0° or 90°, and then thermally laminated. CFRT sheet is a new type of thermoplastic composite material with high strength, high rigidity, high toughness and recyclability. CFRT is a new type of glass fiber reinforced sheet with many properties that surpass thermosetting fiberglass and metal materials.

Advantages of CFRT Sandwich Panels

- Lightweight and High Strength: The outer layer of CFRT sandwich panels uses continuous fiber reinforcement technology, giving it excellent strength and stiffness while maintaining a relatively low weight. This makes it ideal as an alternative to traditional materials, especially in applications where lightweight structures are required.

- Excellent heat resistance: It is usually made of high-temperature thermoplastic materials and has good heat resistance, making it suitable for applications in high-temperature environments.

- Corrosion resistance: Its outer fiber reinforced material usually has good corrosion resistance, making it suitable for use in harsh environments, such as ship manufacturing in marine environments.

- Excellent impact performance: CFRT sandwich panels have good impact resistance due to their strength and toughness, making them suitable for applications that need to withstand impact loads.

- Environmental protection and recyclability: CFRT sheets are made of thermoplastic materials, have good recyclability, and meet environmental protection requirements.

- Ease of processing: CFRT sandwich panels can be processed into different shapes and sizes for easy processing and assembly.

- Long life and durability: CFRT sandwich panels have good durability, are not easily affected by the external environment, and have a long service life.

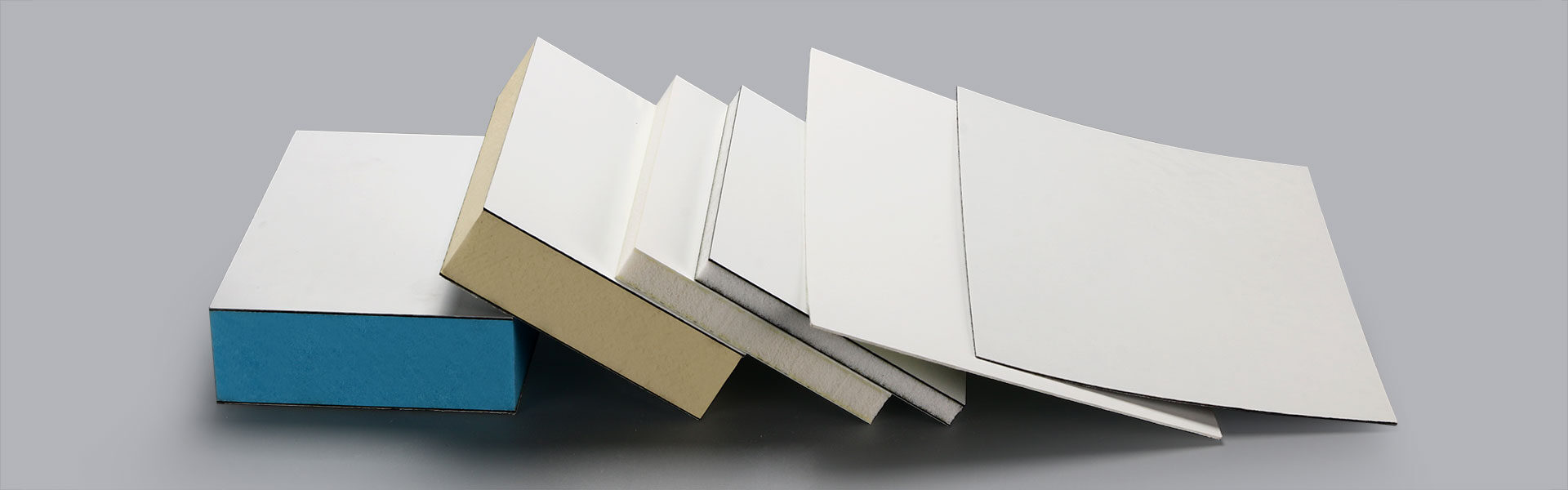

Types of Thermoplastic Sandwich Panels

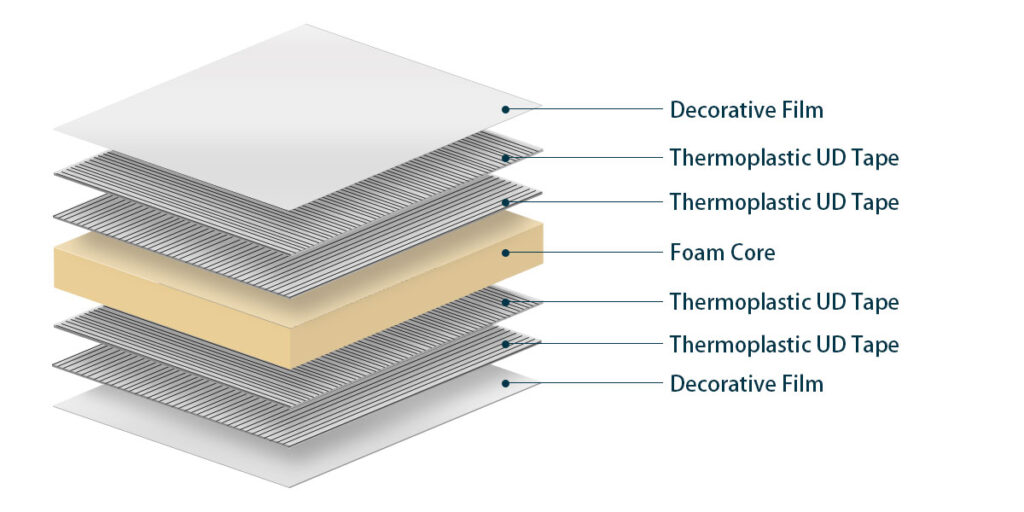

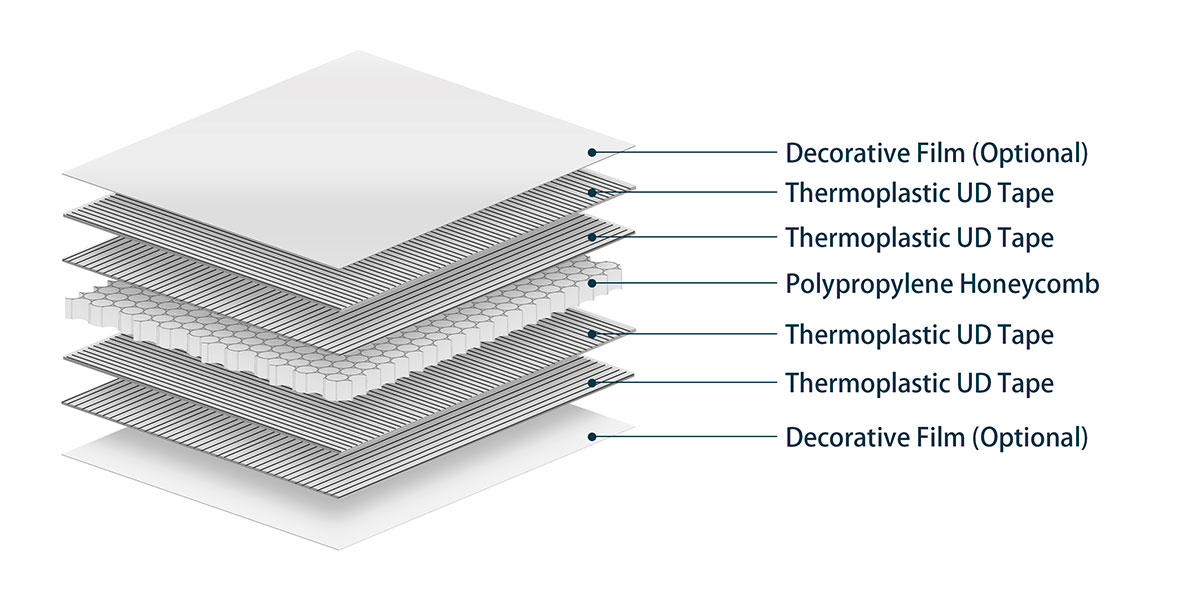

We offer three types of CFRT skinned sandwich panels – foam core sandwich panels, honeycomb core sandwich panels and CFRT plywood sandwich panels.

CFRT Skin Foam Sandwich Panels

CFRT is laminated with various closed-cell foams through adhesives, which can be XPS (extruded polystyrene), PET (Polyethylene terephthalate), PU (polyurethane), PVC (polyvinyl chloride), etc.

Thermoplastic Honeycomb Panels

The core material of the thermoplastic honeycomb panel is a thermoplastic polypropylene honeycomb core, so the CFRT skin and honeycomb core can be combined by thermal lamination.

Application of CFRT Sandwich Panel

CFRT sandwich panels are widely used in construction, manufacturing and transportation.

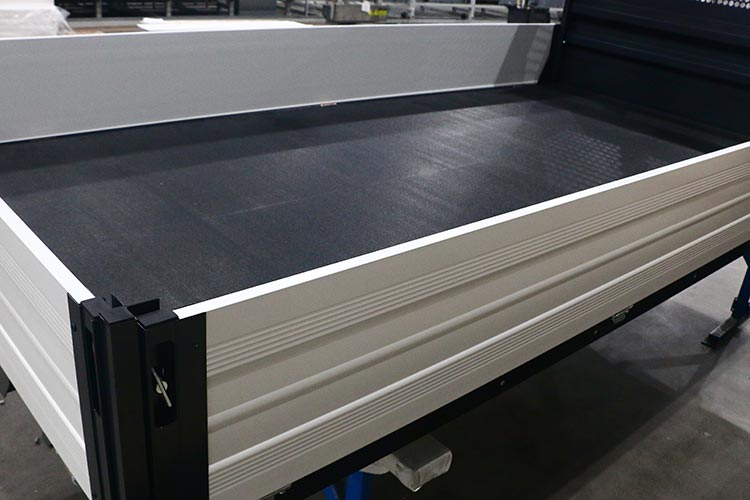

- In the construction field, CFRT sandwich panels are used as walls, roofs, and floors to provide functions such as thermal insulation, anti-skid, and structural support.

- In manufacturing, it can be used to make a variety of lightweight and strong boxes.

- In the transportation industry, it is widely used in vehicle and ship construction to provide structural support and thermal insulation.

Production of CFRT Sandwich Panels

T-panels is an excellent manufacturer of thermoplastic composite panels in the industry. We provide customized solutions for various industries. We use advanced production equipment, high-quality raw materials and scientific production methods.