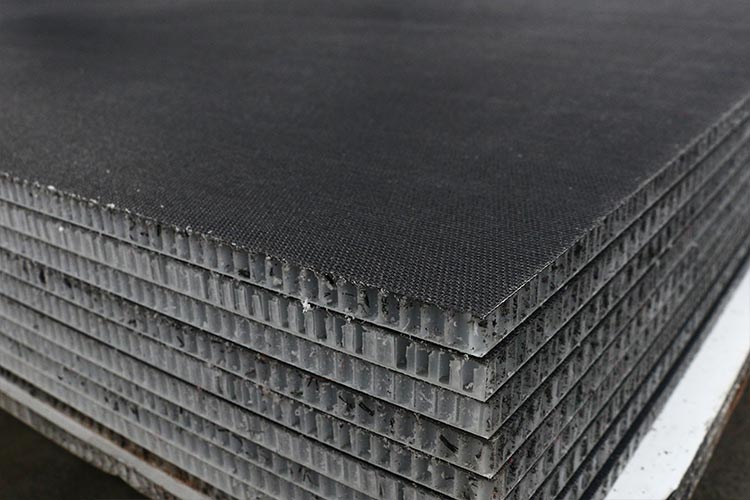

The production of thermoplastic non-slip honeycomb panels does not use adhesives but adopts a thermal lamination process, that is, the outer skin material and the honeycomb core material are laminated together, and then they are heated and pressed together by the thermal lamination process, so that the core material tightly bonded to the skin. Thermoplastic anti-skid honeycomb panels are different from traditional metal pattern anti-skid panels. It has the characteristics of lightweight, high strength and corrosion resistance. The dense anti-slip texture on the surface provides a better anti-slip effect.

Specifications

- Surface Material: Anti-skid CFRT sheet.

- Core Material: PP honeycomb.

- Surface Color: Black, gray.

- Length: within 12m.

- Width: within 3.2m.

- Thickness: 15.25-15.50mm.

- Areal Weight: ≤5486g/m2.

- Flexural Strength: ≤135MPa.

- Max. Load: ≤2815N.

- Anti-ultraviolet grade: F1.

- Flame retardant grade: B2.

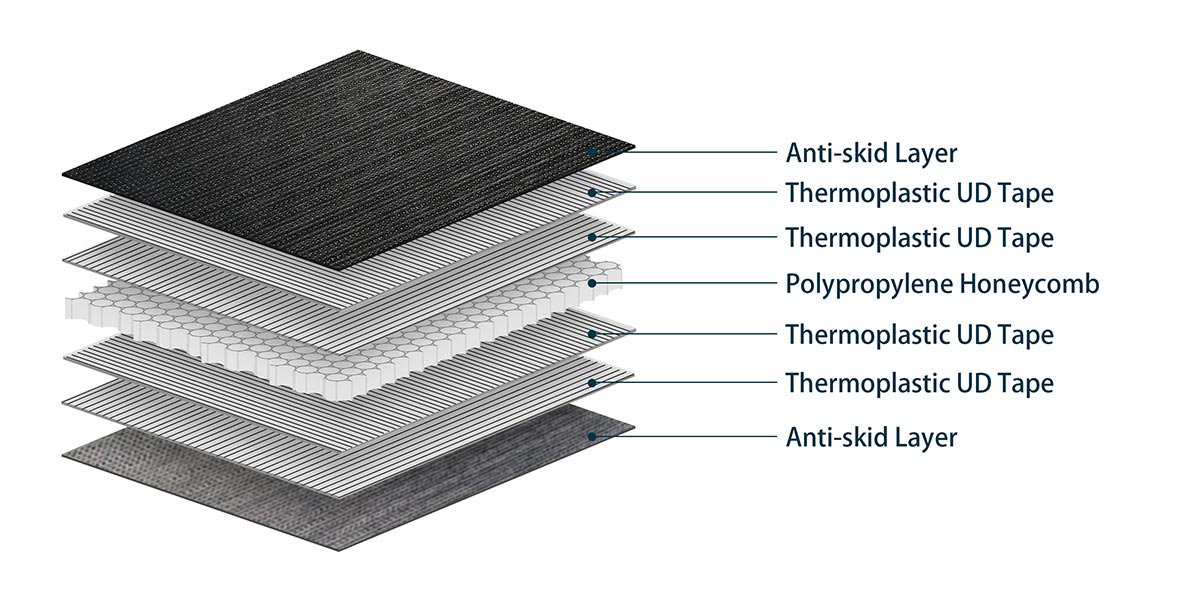

The Structure of Non-slip Honeycomb Panel

- Surface Layer: The surface layer is a continuous fiberglass thermoplastic composite sheet (CFRT), and the outermost layer is a hard non-slip texture layer with anti-ultraviolet treatment.

- Honeycomb Core Layer: The middle layer adopts PP (polypropylene) honeycomb, which provides a stable structural support, effectively reduces weight, and realizes lightweight materials.

Applications

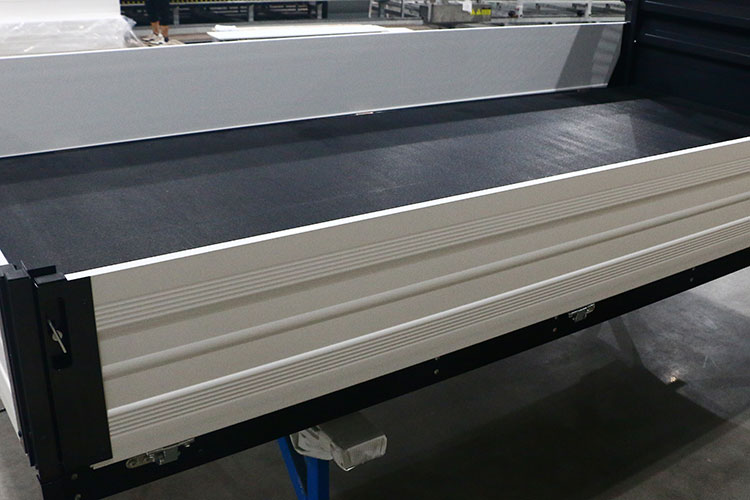

Thermoplastic non-slip honeycomb panels are widely used in construction, especially in applications such as floors, steps, stairs, ramps, etc. where safety surfaces are required, walkways and industrial places. It can also be used in other occasions that require anti-skid performance, such as truck floors, playgrounds, sports fields, docks, track and field fields, etc.