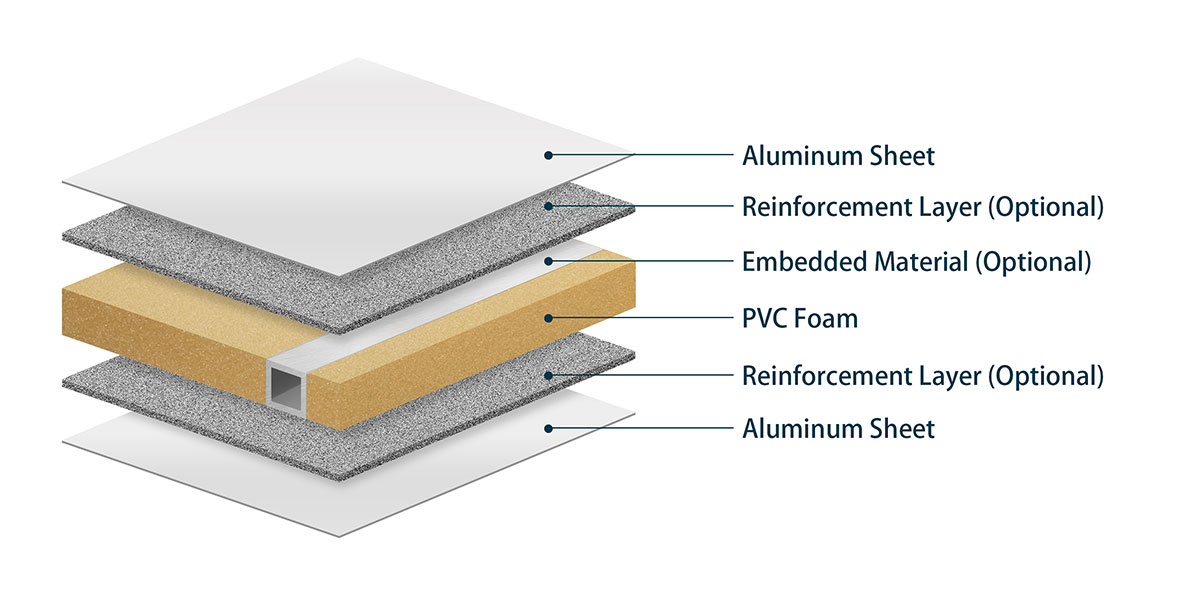

Aluminum PVC sandwich panels are composite materials consisting of two layers of aluminum sheets bonded to a core material made of PVC (polyvinyl chloride) foam. This sandwich structure combines the lightweight and corrosion-resistant properties of aluminum with the insulating and weather-resistant characteristics of PVC foam.

Basic Structure

- Aluminum Sheets: The outer layers of the sandwich panel are made of aluminum sheets. Aluminum provides the panel with strength, lightweight properties, and resistance to corrosion. The surface of the aluminum sheets can be coated or treated to enhance durability and aesthetics.

- PVC Foam Core: The core material is made of PVC foam, which is a lightweight, closed-cell foam. PVC foam provides excellent thermal insulation, soundproofing properties, and resistance to moisture and weather. It is commonly used in applications where resistance to water and weather is essential.

Basic Specifications

- Total Thickness: 10~120mm.

- Aluminum Sheet Thickness: ≥0.1mm.

- Width: 800~2600mm.

- Length: ≤12m.

- Aluminum Grades: 1050, 1060, 1100, 1145, 1200, 1230, 1350, 2011, 2014, 2017, 2018, 2124, 2219, 2319, 3003, 3004, 3105, 5005, 5052, 5083, 5086, 6061, 6063 ,7075, 7050, 7049, 710 0, 8006, 8111, 8079, etc.

- Aluminum Surface Treatment: sandblasting, polishing, glossy, embossed, matte, fluorocarbon coating, anodizing, etc.

- Aluminum Surface Color: RAL color, or customized pattern.

- PVC Foam Density: 40~250kg/m³.

Application of Aluminum PVC Sandwich Panels

- Buildings: PVC panels are used for exterior and interior cladding, roofing and partition walls of buildings.

- Vehicles: Aluminum PVC sandwich panels are used in the manufacture of lightweight components for vehicles including vans, caravans, RVs (recreational vehicles) and trailers.

- Boats: Aluminum PVC sandwich panels can be used in marine applications where lightweight and weather-resistant materials are required, such as cabins and bulkheads.