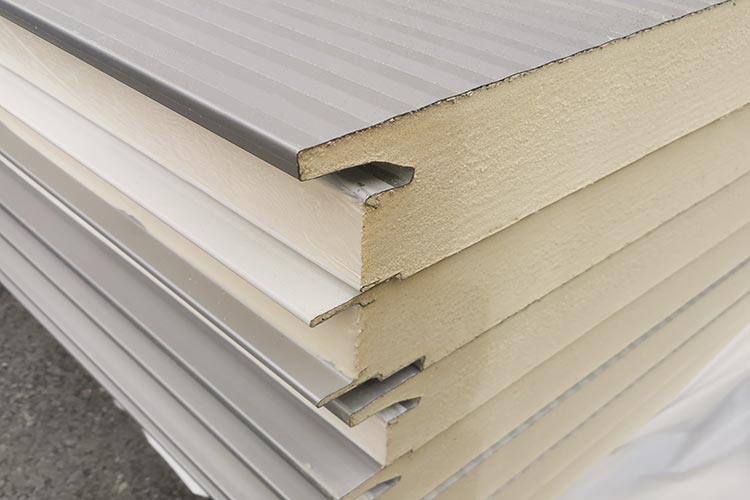

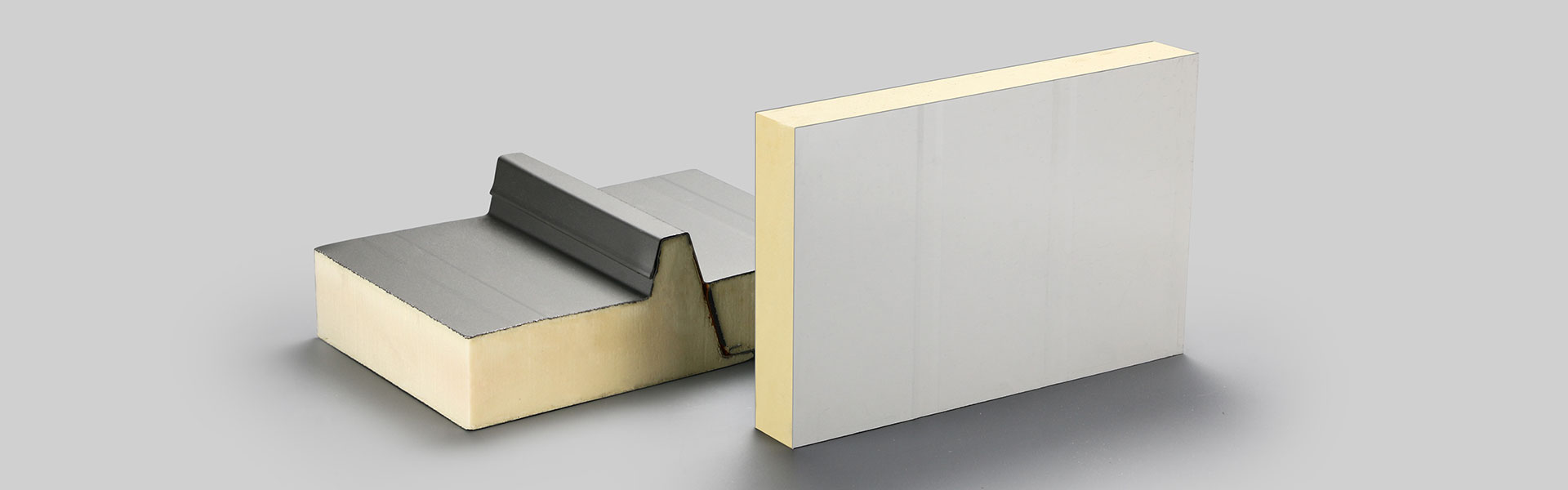

PIR sandwich panels are high-performance thermal insulation materials widely used in construction and industrial applications. Its structure is relatively simple, usually made of PIR foam core sandwiched between two layers of metal sheets. This structure gives the sandwich panel excellent structural strength and thermal insulation properties. It is also lightweight, easy to install, and durable.

Basic Specifications

- Skin Materials: Aluminum sheet, PPGI, PPGL, stainless steel sheet.

- Surface Treatment: Fluorocarbon coating, embossing, etc.

- Surface Color: RAL series.

- Core Materials: Polyisocyanurate foam (Density: 30~60kg/m³).

- Length: Customized.

- Width: Customized.

- Thickness: 50/75/80/100/120/150mm, or customized.

- Flame Retardant Grade: B1.

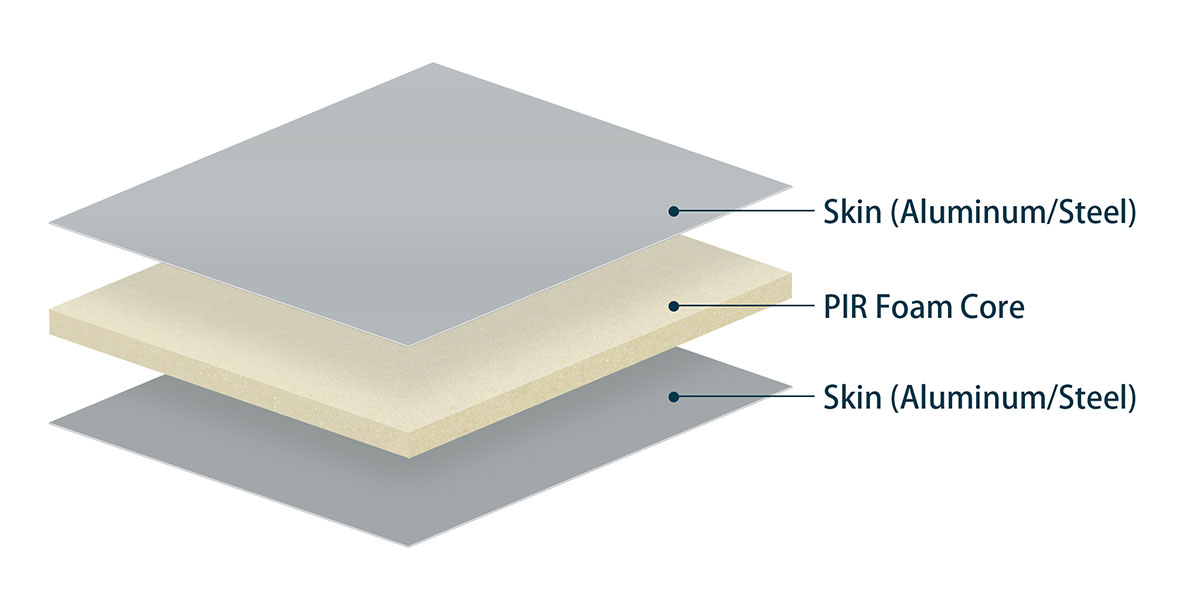

Basic Structure

- Core Material: PIR (Polyisocyanurate) foam is a high-performance thermal insulation foam material, which is a type of polyurethane foam. It is composed of polyisocyanate resin and foaming agent and has excellent thermal insulation and flame retardant properties.

- Skin Layer: The skin materials of PIR sandwich panels are usually pre-coated galvanized steel (PPGI/PPGL), aluminum alloy, and stainless steel. Usually, the metal surface is treated with fluorocarbon coating to enhance its weather resistance, and the surface color can be selected within the RAL color range.

PIR Performs Better Than PUR

- The thermal conductivity of PIR is lower than that of PUR, so the thermal insulation performance of PIR is relatively better.

- PIR has better flame retardant properties and is not easy to burn even in a fire.

- The mechanical strength of PIR is better than PUR.

PIR Foam VS PUR Foam

| Item | PIR | PUR |

| Flame Retardant | B1 | B3 |

| Thermal Insulation W/mK (25°C) | 0.019 | 0.022~0.026 |

| Density (kg/m³) | 30~60 | 30~60 |

| Temperature Resistant (°C) | -196°C~+205° | -185°C~+110 |

| Water Absorption (%) | ≥0.9 | 2.5%~3.0% |

Surface Types

There are 4 types of surfaces for PIR sandwich panels for you to choose from: Flat type, Micro ribs, Profiled ribs, and Wide ribs. We also customize special types of panels for your project.

Applications

PIR sandwich panels are suitable for building walls, roofs, floors, door panels and truck boxes. It can help buildings maintain stable indoor temperatures, reduce energy consumption and lower energy bills.

Application Temperature and Thickness (Recommended)

| Application Temperature | Thickness |

| Temperature 5°C or above | 50mm |

| Temperature -5°C or above | 75mm |

| Temperature -5°C~-25°C or above | 100mm |

| Temperature -18°C~-45°C or above | 150mm |

| Temperature -55°C or above | 200mm |

Our Product Advantages

T-Panels PIR sandwich panels use new polyurethane pentane B1 rigid foam as the core material, which can more effectively reduce thermal conductivity and have better thermal insulation and fire resistance.

- The reasonable plug-in interface design not only maintains the strength of the board but also ensures the thermal insulation effect.

- Surface weathering treatment can effectively resist rain, sunlight, wind, snow, frost and other weather conditions.

- It meets various major fire protection standards around the world and ensures the safety of buildings.

- The volatile amount of organic compounds (VOC) is extremely low and will not cause harm to the environment and human body.