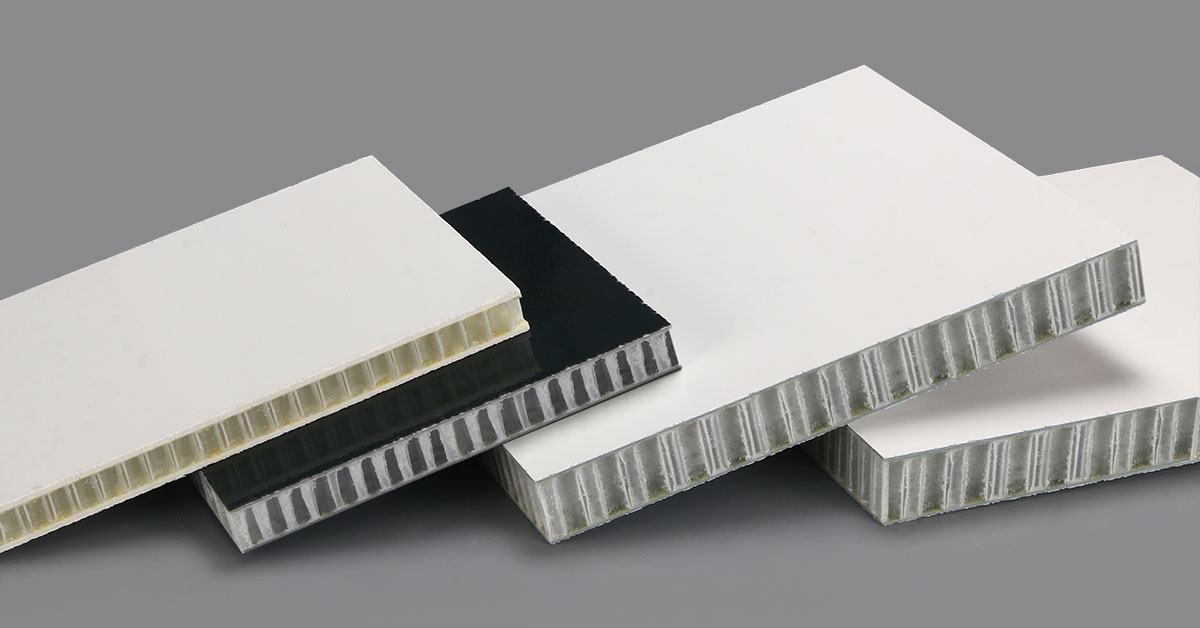

GRP honeycomb panels with excellent characteristics of lightweight and high strength. PP honeycomb and GRP sheet are bonded together with adhesive, which is a significant difference from thermoplastic honeycomb panels.

Performance of GRP Honeycomb Panels

- Lightweight: Due to its honeycomb structural core, GRP honeycomb panels are extremely lightweight, providing excellent strength and stiffness at a relatively low weight ratio.

- High Impact Resistance: It can withstand general impacts and the surface will not be damaged.

- Higher Bending Resistance: The hardness of GRP is higher, and GRP PP honeycomb panels will not undergo large deformation.

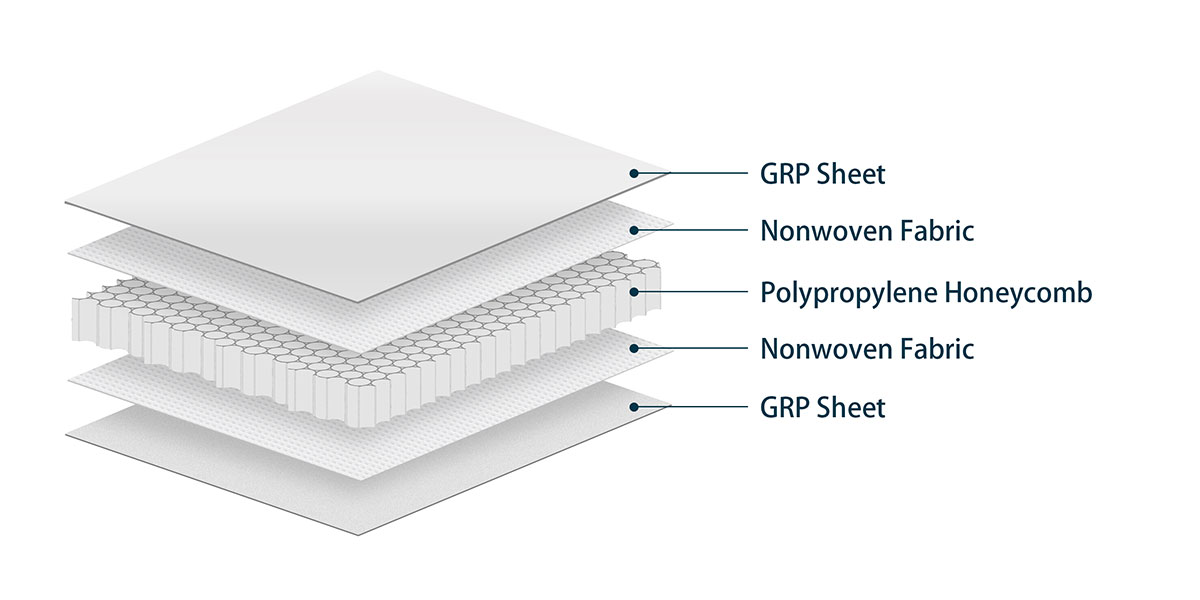

The Schematic of Structures

- GRP Surface Layer

It has the characteristics of high strength, lightweight, corrosion resistance, strong weather resistance, and good insulation. - Connecting Layer

The non-woven fabric can make the core material and the surface layer more closely bonded, and at the same time increase the strength of the composite panel. - Honeycomb Core Layer

The honeycomb core material made of PP (polypropylene) can not only increase the strength and rigidity of the panel, but also maintain the lightweight performance of the panel.

Basic Specifications

- Skin Material: Gelcoat GRP Sheet. (Thickness 0.7~5.0mm)

- Core Material: Polypropylene Honeycomb. (Cell diameter: 80/120mm)

- Length: Within 12m.

- Width: Within 3.2m.

- Thickness: 10~120mm.

- Surface Color: RAL color.

- Surface Treatment: Gelcoat; Embossed, etc.

- Fire Rating: B2.

- UV Resistant: F1.

Surface Treatment

In addition to the most common glossy and matte surface treatments, the GRP surface can be processed into various texture patterns, etc., and it can also be coated with other materials (such as gravel).

Our Productivity Advantages

- The one-piece GRP composite panel that can be produced is up to 12mm without any trace of splicing.

- The error is small and processed using high-precision CNC machine tools.

- High-efficiency production, reaching a production speed of one composite board every five minutes.

Applications of GRP Honeycomb Panels

- Box Material: GRP honeycomb panels can be used as wall panels, floors, and ceilings for RVs and dry cargo trucks.

- Buildings: Partition materials for various buildings, such as farms, playgrounds, and commercial buildings.

- Furniture: desktops, door panels, chair panels, bed panel, cabinets, etc.

- Yachts: The deck of a yacht.