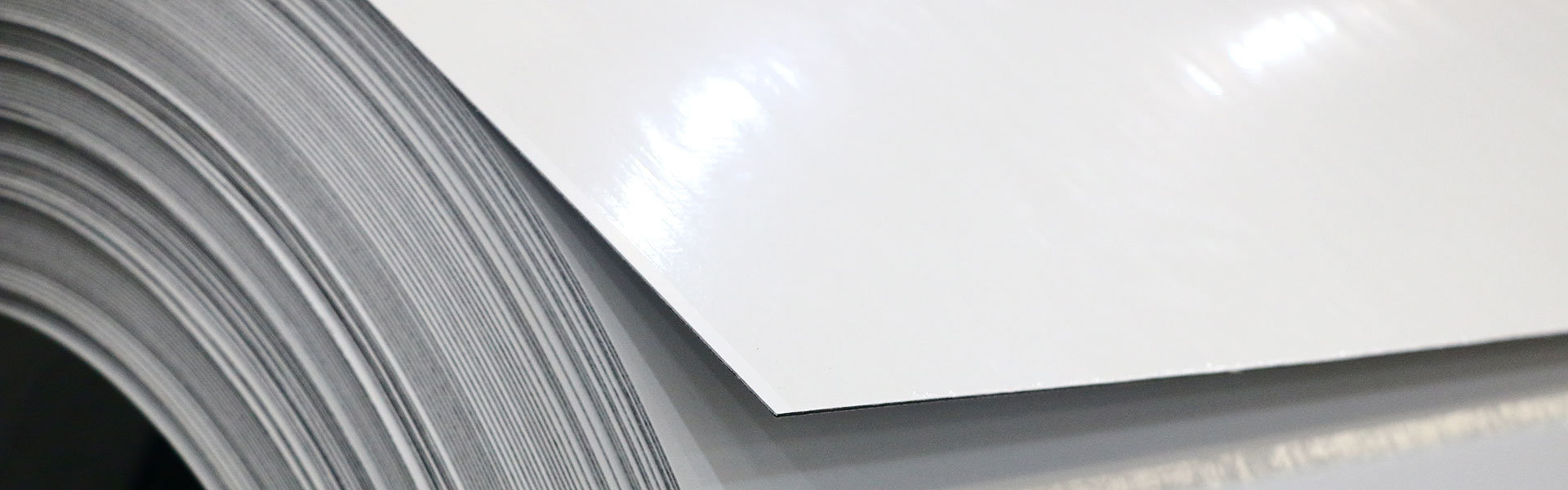

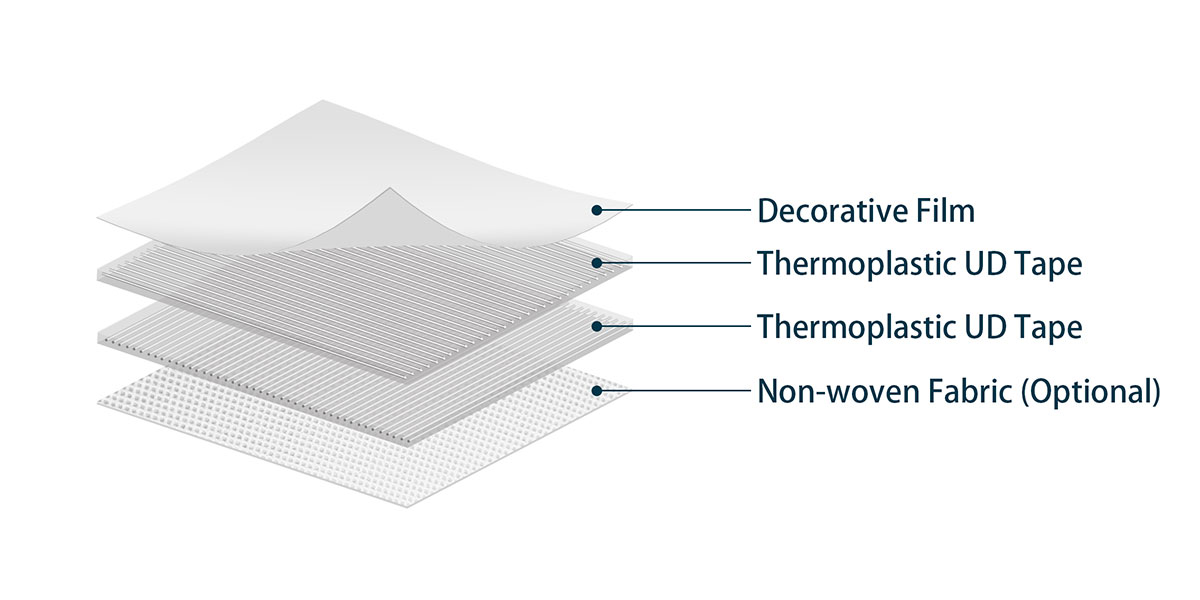

The continuous fiberglass thermoplastic composite sheet (CFRT) is made of double-layer or multi-layer thermoplastic unidirectional prepreg tapes at an angle of 0° or 90°, and then thermally laminated. CFRT sheet is a new type of thermoplastic composite material with high strength, high rigidity, high toughness and recyclability. Usually, its surface is covered with a decorative film and the back is covered with a layer of non-woven fabric.

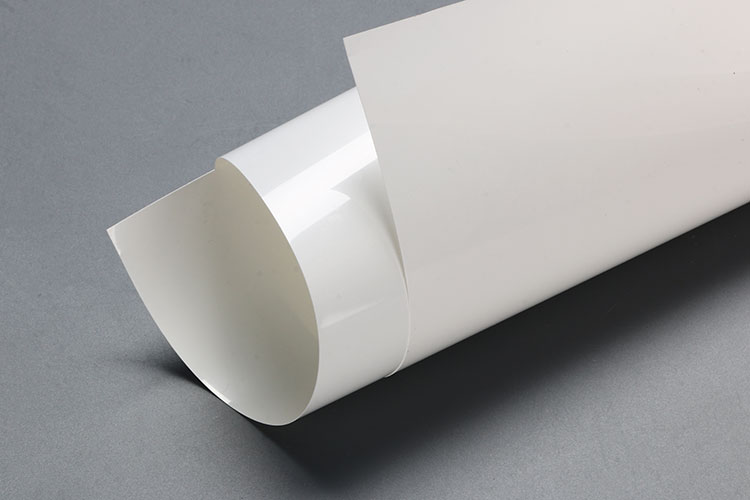

- PP/PVC/PET and other protective films can be selected, which can not only play a decorative role, but also play waterproof and moisture-proof functions.

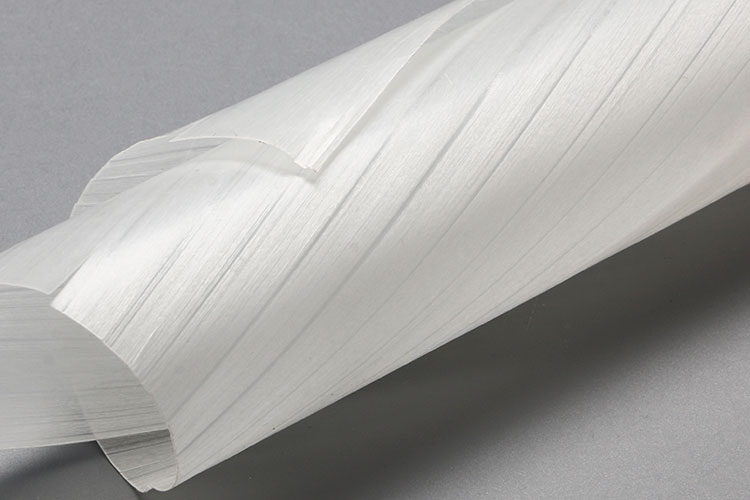

- UD tapes are heat-pressed together at different angles and with different numbers of layers (more than two layers). This structure ensures the structural strength of the sheet in both transverse and longitudinal directions.

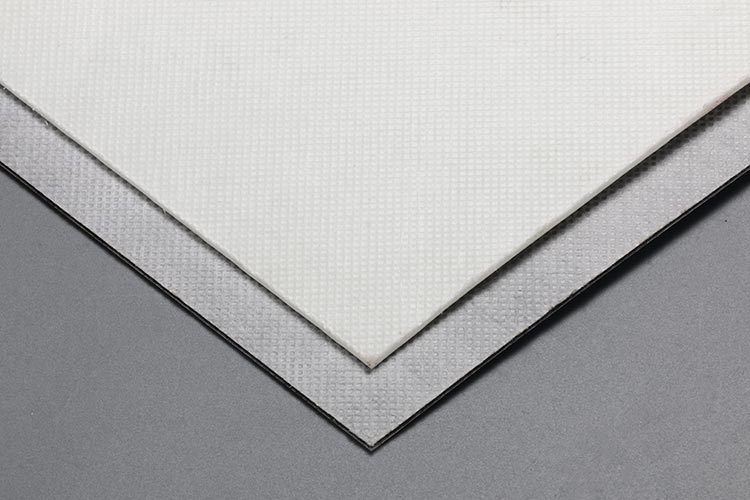

- The non-woven fabric can promote the tighter adhesion of the CFRT sheet to other material systems.

Basic Specifications

- Resin Types: Polypropylene (PP), polyethylene (PE), nylon (PA), polyphenylene sulfide (PPS), etc.

- Layers of UD tape: 2~9 layers, the number of layers can be customized.

- Thickness: 0. 4~10mm.

- Width: ≤3.2mm.

- Surface Color: Natural/black, other colors can be customized.

- Surface Treatment: Anti-ultraviolet protective film.

- Anti-ultraviolet Grade: F1.

- Optional: Non-woven backing.

Feature of CFRT Sheets

The density of CFRT is only 1/4~1/5 of steel and 1/3~1/2 of aluminum. It has outstanding specific strength and can achieve substantial weight reduction. Its outstanding features are reflected in:

- High Rigidity

The continuous fiberglass structure gives CFRT excellent toughness, and large bending deformation will not cause damage to its structure.

- High Strength

Compared with metal materials and thermosetting composite materials, it can absorb a larger amount of energy when it is impacted, and reduce the damage caused by impact.

- Scratch Resistant

General impacts and scratches will not leave marks on its surface.

- Corrosion Resistance

The protective film on the surface of CFRT can completely isolate moisture and general chemicals, which makes its surface easy to clean.

CFRT VS GRP

As a new type of GRP material (popularly, people often refer to thermosetting glass fiber reinforced sheets as GRP), CFRT and GRP have their own advantages.

| Material | GRP | CFRT |

| Rigidity | Good | Very good |

| Impact Strength | Good | Very good |

| Scratch Resistant | Good | Very good |

| Surface Smoothness | Very good | Good |

| Corrosion Resistance | Very good | Good |

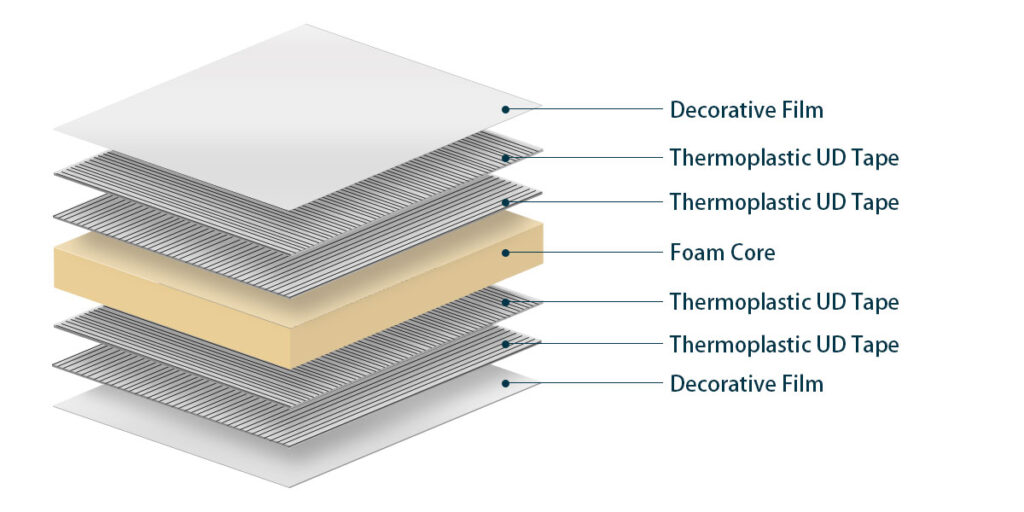

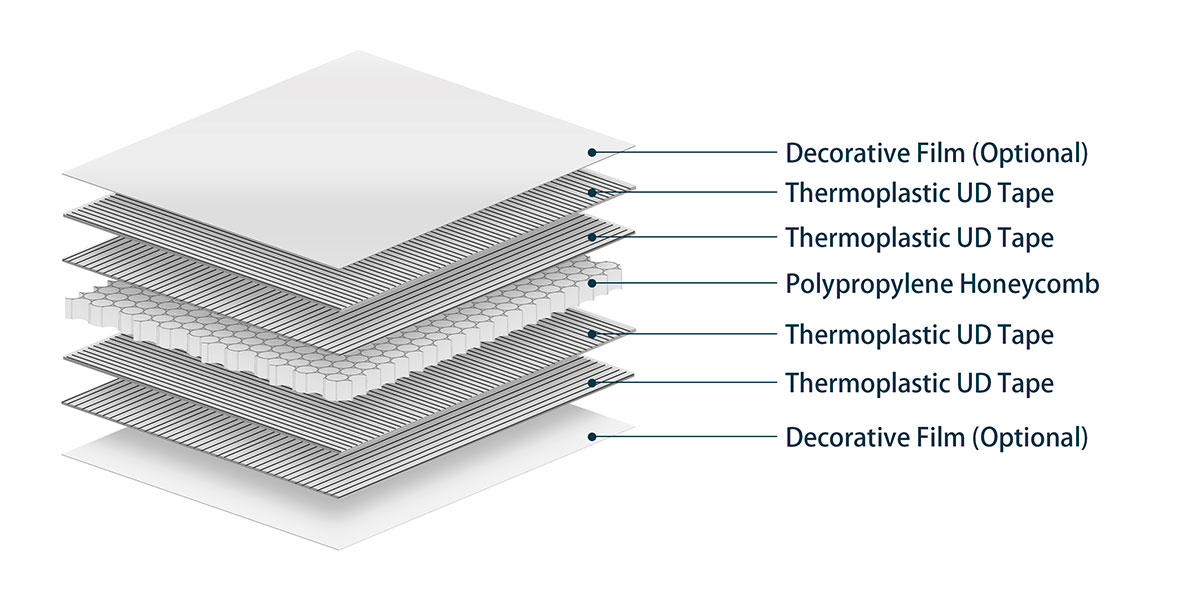

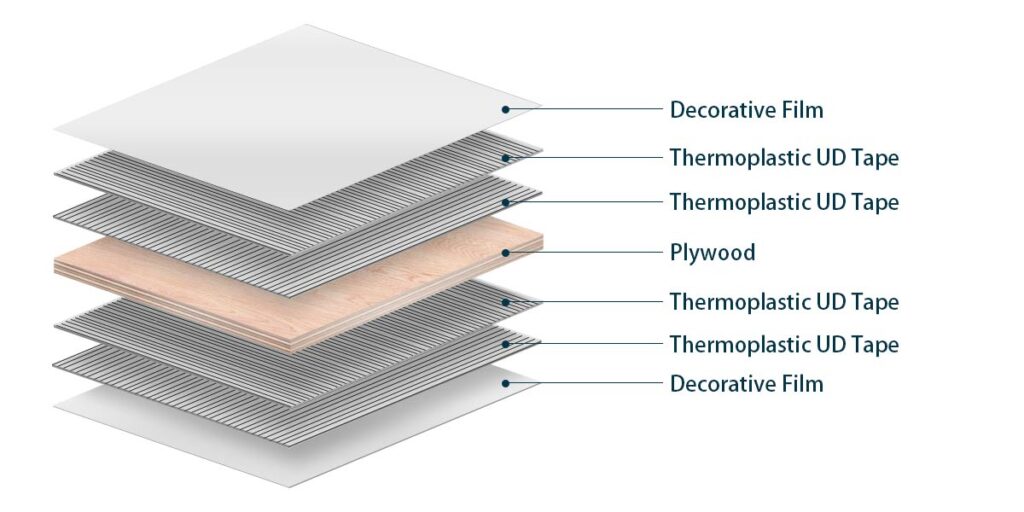

CFRT Sandwich Panels

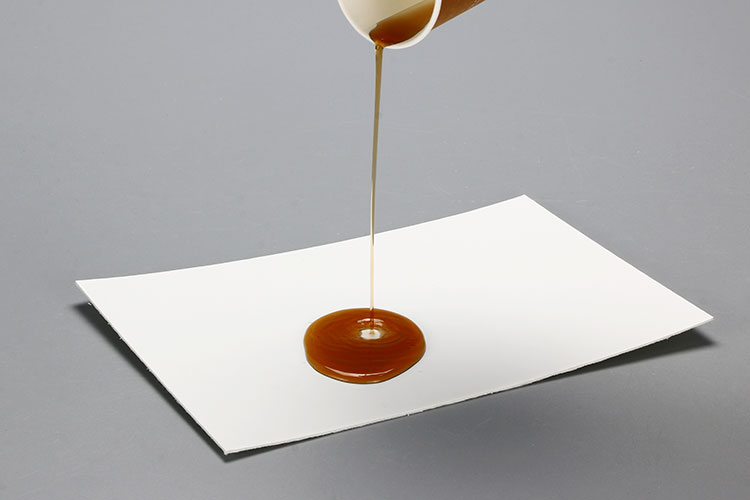

CFRT sheets can be composited with PP honeycomb, foam (XPS/PET/PU/PVC), plywood, etc., and are used in ships, RVs, vans, rail transit, construction, furniture, etc. One feature of CFRT is that it can not only be composited with other core materials through adhesives, but can also be laminated with thermoplastic core materials through heat melting.

Custom CFRT Sheets for Your Project

We provide appropriate material solutions based on your project needs.

- Different resin systems and fiberglass contents are used according to needs.

- Provides composite testing.

- Provide performance test reports.