GRP Sandwich Panels

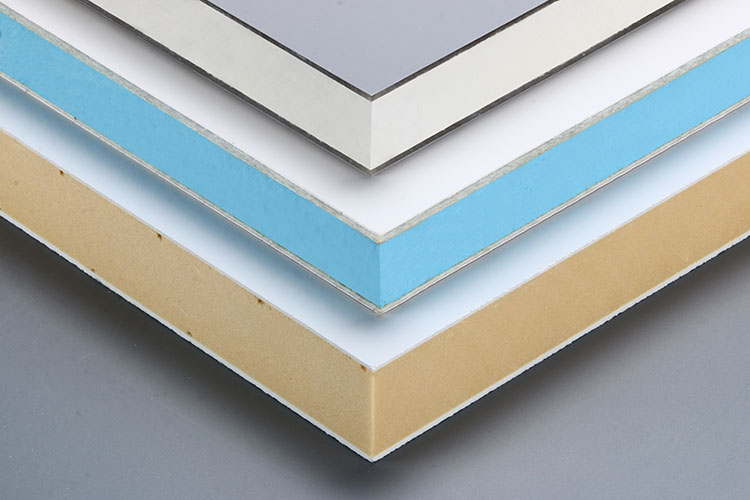

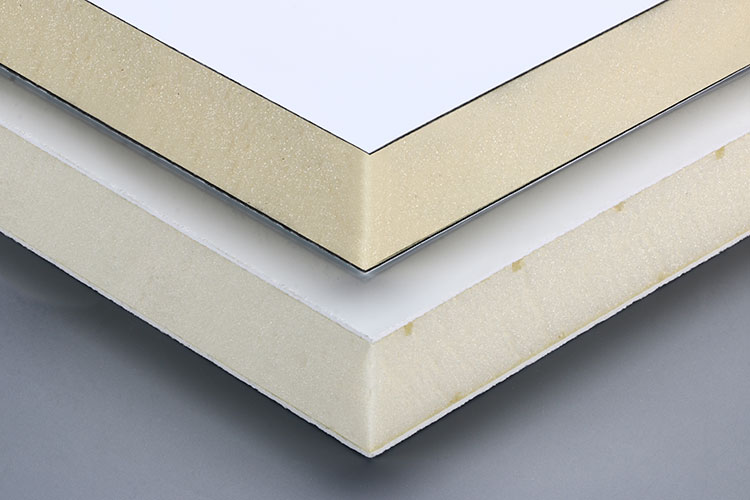

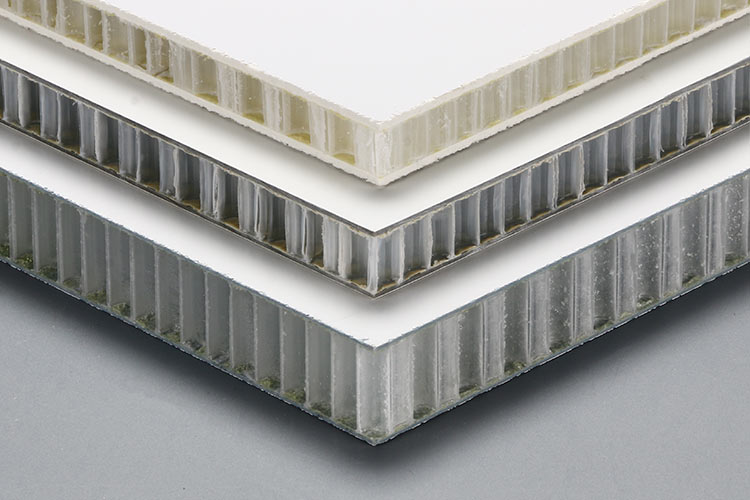

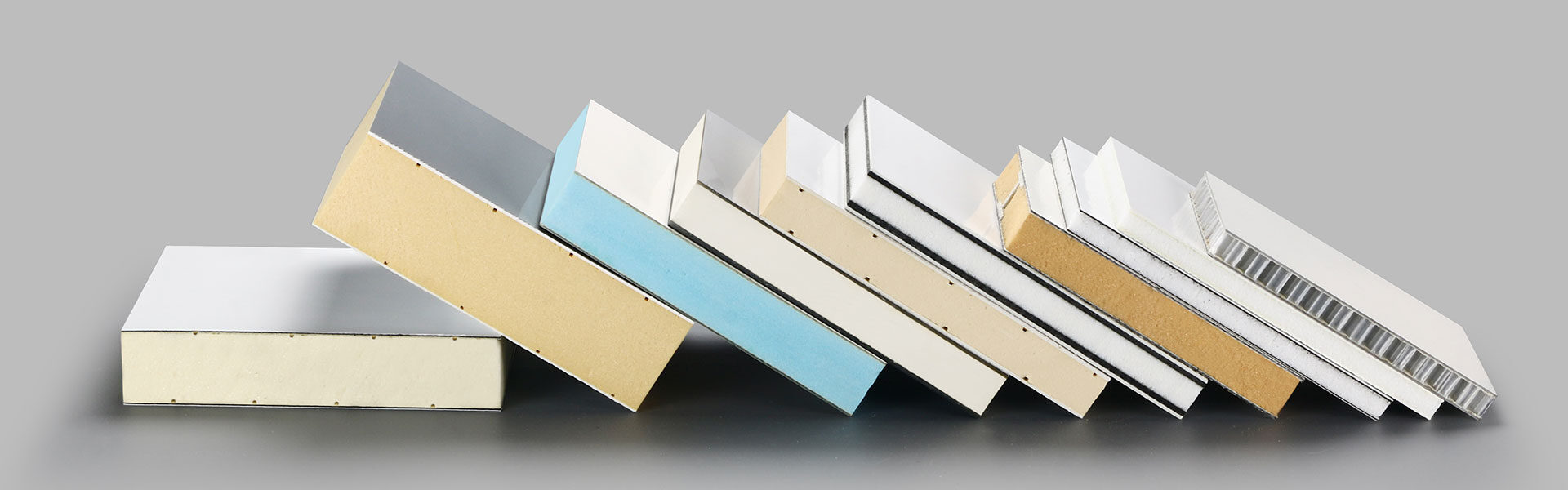

Foam Core, Honeycomb Core, Plywood Core

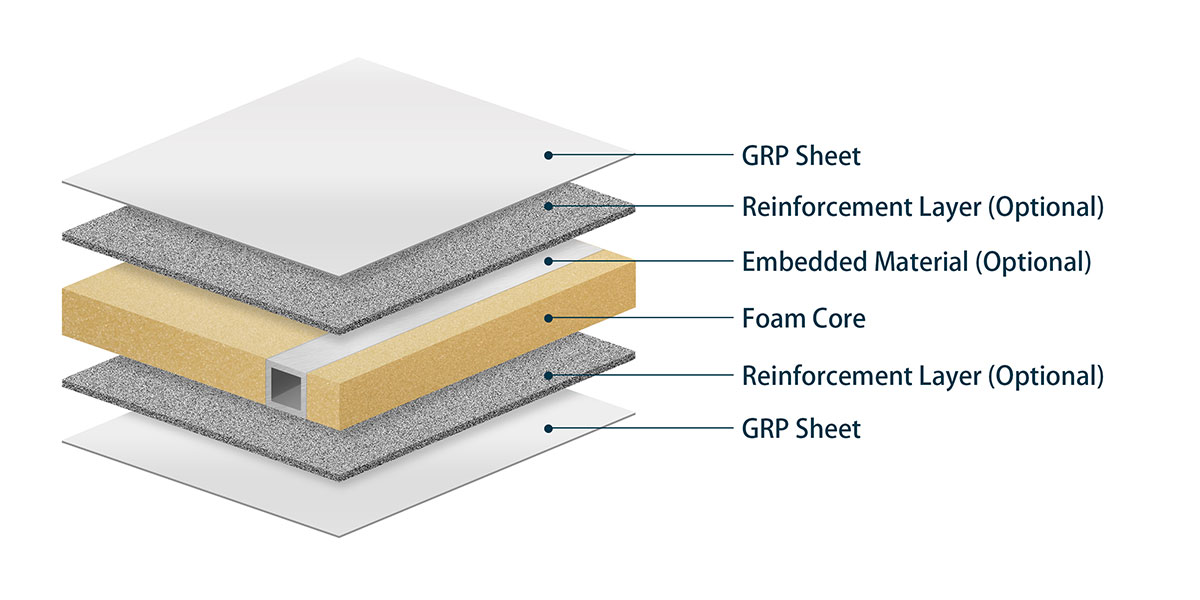

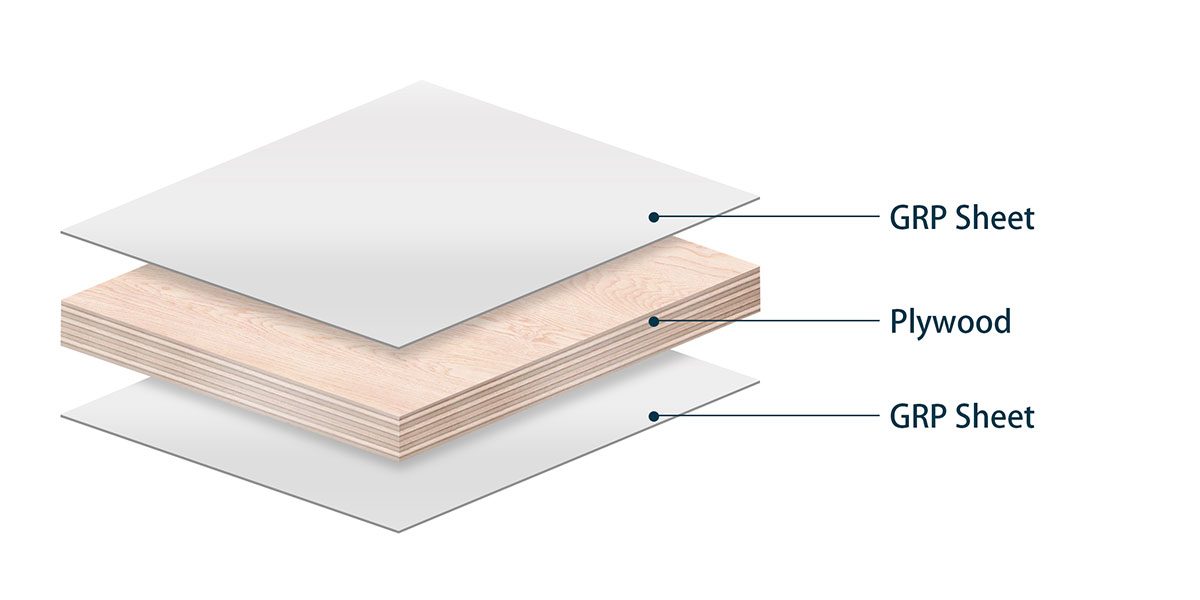

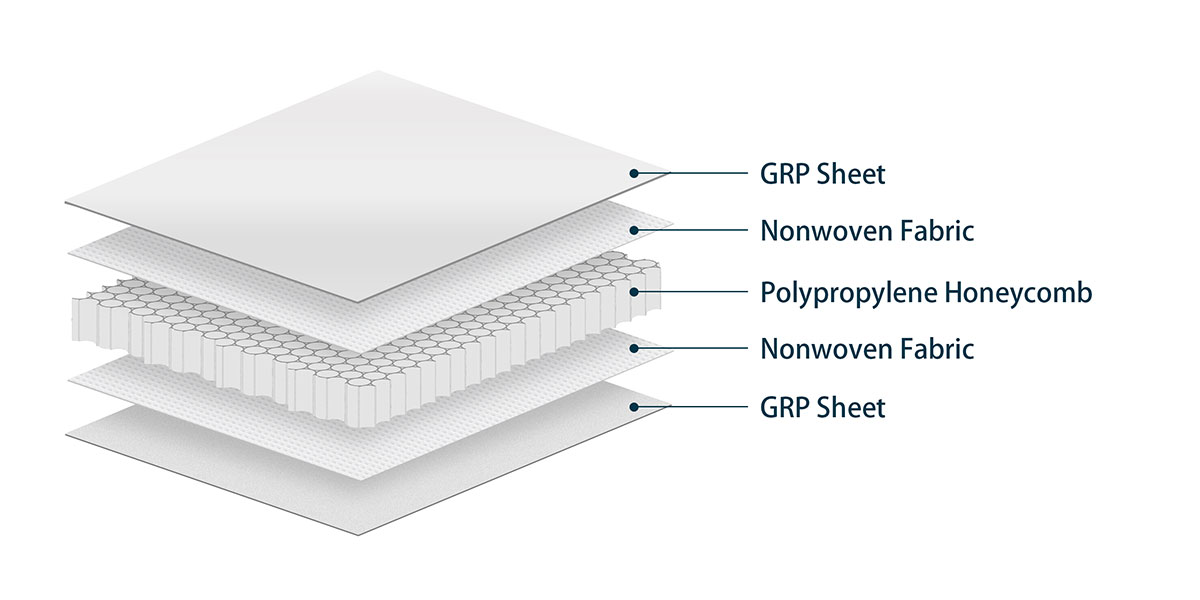

GRP sandwich panels are also called fiberglass or FRP sandwich panels, which are composed of two layers of fiberglass reinforced resin skins sandwiching a middle core layer. It is a new type of composite material, which has been applied in many fields with the development of the demand for lightweight materials. T-Panels provide customers with a series of faster, more economical and more reliable GRP composite panel solutions. We have internationally advanced composite panel production lines and many years of industry experience and have participated in many projects, which enables us to always provide customers with the best product quality and reduce cost expenditures.

Basic Specifications

- Skin Materials: GRP/FRP sheet, CFRT sheet (Continuous fiber reinforced thermoplastic).

- Core Materials: XPS, PET, PVC, PU,PMI foam core; PP honeycomb core; plywood; balsa wood, etc.

- Performance Rreatment: anti-ultraviolet, flame retardant, antistatic.

- Length: ≤12m.

- Width: ≤3.2m.

- Total Thickness: 10~120mm, or customized.

Our Quality Assurance

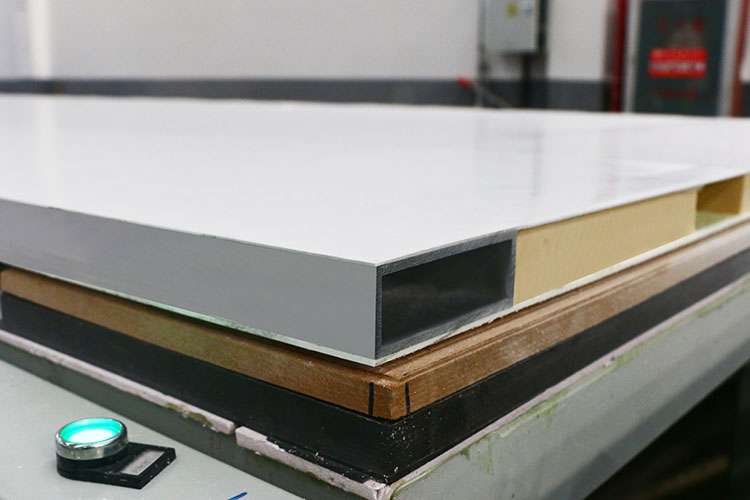

- The core material is tightly bonded to the skin, with no delamination or edge warping.

- The surface is smooth and flat, no macula, no black spots, no convex and other problems.

- The product can be used in the temperature range between -40~+80°C.

- Stable color: Our GRP panels with excellent anti-ultraviolet radiation performance, and can maintain long-term non-fading and non-yellowing.

Features of GRP Sandwich Panels

Lightweight

The density of GRP/FRP materials is between 1.5 and 2.0 g/cm³, and the core materials selected are mostly low-density foam and honeycomb cores.

High Strength

The toughness of the GRP/FRP material combined with the compressive strength of the core material gives it high strength.

Waterproof

GRP/FRP material is naturally non-hydrophilic, and can completely isolate water and vapor from the outside of the panel.

Corrosion Resistance

GRP/FRP will not chemically react with general acid and alkali.

Anti-ultraviolet

Anti-aging agent is added inside GRP/FRP, which can prolong the service life of the panel.

Environmental Protection

Fiberglass reinforced sandwich panels can effectively reduce energy consumption, and GRP materials and plastic core materials are usually recyclable.

Types of GRP Sheets

We provide two different GRP sheets as skin materials for sandwich panels: Thermoset GRP sheets and Thermoplastic CFRT sheets.

Surface Treatment of GRP Sheet

The surface of GRP sheets can be added with gel coat coating or decorative film to obtain rich texture and gloss effects.

Core Materials for GRP Sandwich Panels

The core materials used in FRP sandwich panels with superior compression resistance. Typically, these materials include rigid foam, polypropylene honeycomb, plywood, etc., and GRP sheets can be tightly bonded to these core materials using adhesives.

Choose GRP composite panels you are interested in

Our Customized Services

- We use 5-axis synchronized high-precision CNC machining for trimming and post-processing of GRP panels, such as cutting, drilling, chipping, etc. We have a 3.2*12m CNC machining operation platform that can process oversized GRP panels.

- Each batch of FRP sandwich panels must pass strict quality inspection. We will conduct a series of tests such as pressure resistance test, peeling, acid and alkali resistance, high temperature resistance, and UV resistance.

- We will customize a variety of spare parts for your project to facilitate quick assembly of the panels.

- We customize solutions for each packaging and transportation, which not only ensures the safety of the panels during transportation but also facilitates users to unload the goods.

Applications of GRP Sandwich Panels

The many advantages of fiberglass sandwich panels make it widely used in construction, ships, vehicles, sports and other fields. FRP sandwich panels provide thermal insulation, weight reduction, water and moisture resistance, antibacterial and other benefits for these applications.