Polypropylene Honeycomb Panels

Lightweight & High Strength

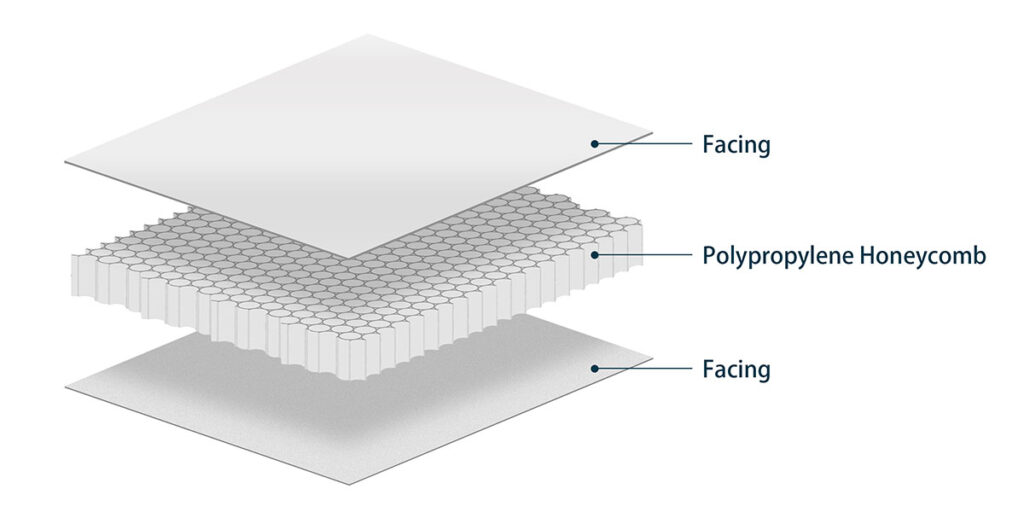

The polypropylene honeycomb sandwich panel consists of two outer skin layers and a honeycomb core material in the middle. It is a composite panel with both strength and lightness. Due to its excellent performance, it is used as one of the preferred materials for lightweight development and is widely used in many fields.

Our Product Specifications

- Outer Layer: GRP (Glass Fiber Reinforced Plastic), CFRT (Continuous Fiber Reinforced Thermoplastic), ACP (Aluminum Composite Panel), other materials.

- Core: Polypropylene honeycomb.

- Length: ≤12m.

- Width: ≤3.2m.

- Thickness: 6.0~120mm.

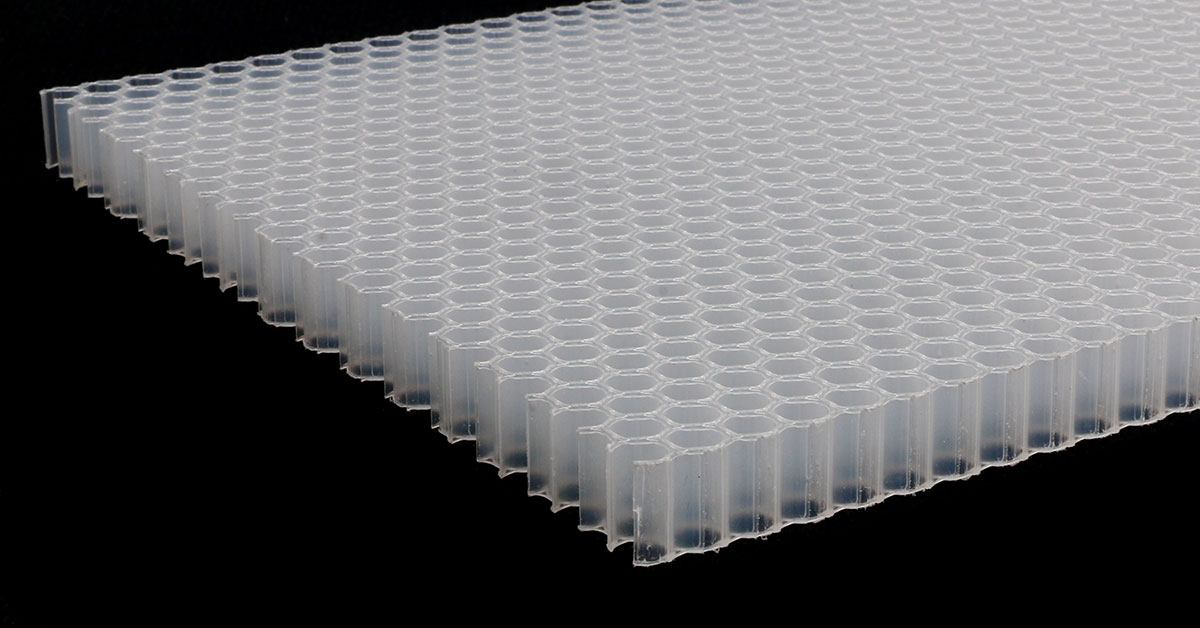

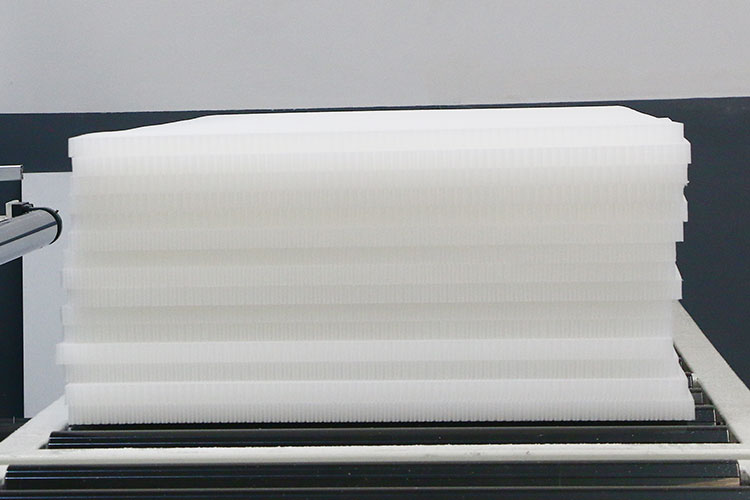

Polypropylene Honeycomb

The structure of a polypropylene honeycomb is similar to bee honeycomb, and the common honeycomb shapes are hexagonal and circular. PP (Polypropylene) honeycomb is lightweight, high-strength, corrosion-resistant, and waterproof. Polypropylene honeycomb core sandwich panels made of it as the core material are suitable for various application fields.

Types of Polypropylene Honeycomb Panels

Polypropylene honeycomb can be composited with different types of skin materials through adhesives or hot melt glue. Such as GRP (FRP) sheet, CFRT (continuous fiber reinforced thermoplastic) sheet, ACP (aluminum composite panel), PVC artificial leather, etc.

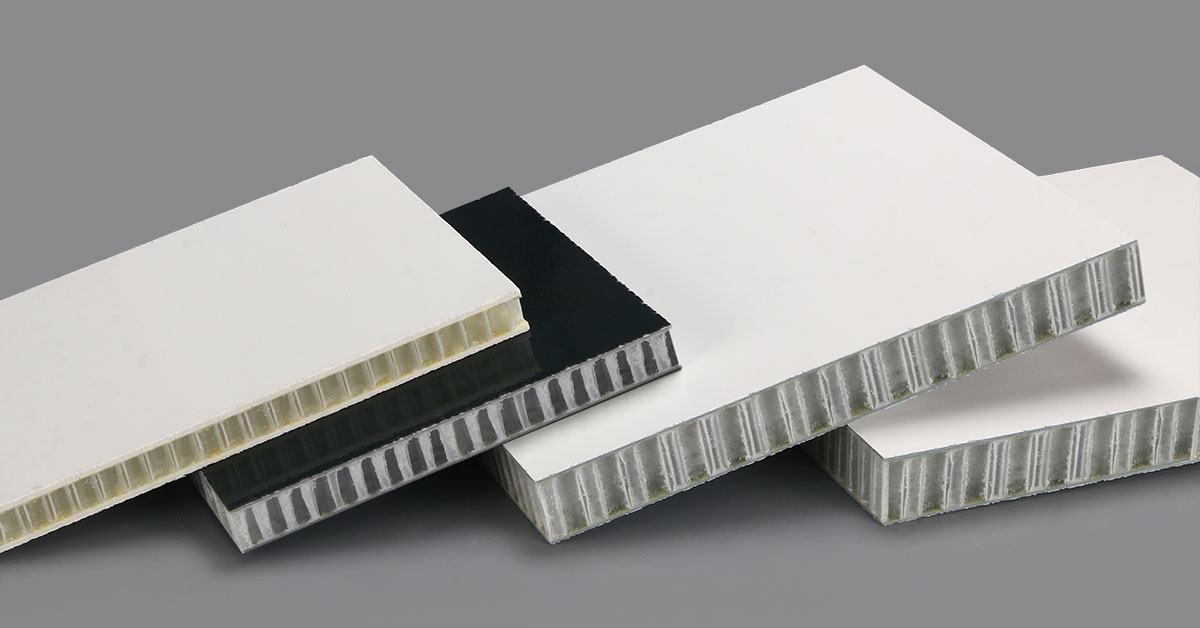

GRP Facing PP Honeycomb Sandwich Panels

- Facing: GRP ((Glass Reinforced Thermoplastic) sheet.

- Core: Polypropylene honeycomb.

- Manufacturing Process: Press laminates composite

GRP sheets are light in weight, high in strength, corrosion-resistant, waterproof and have a smooth surface. GRP honeycomb panels have high resistance to deformation.

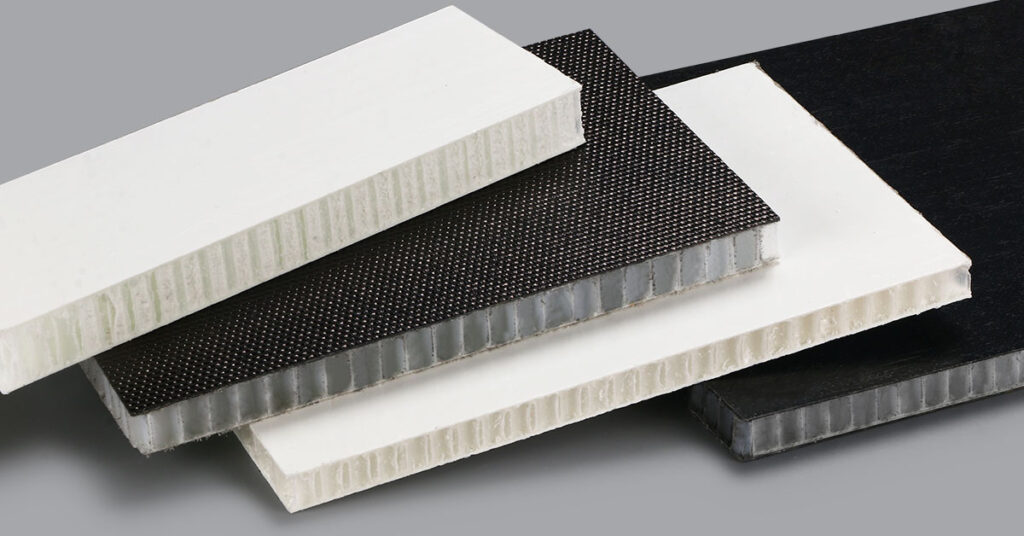

Thermoplastic PP Honeycomb Sandwich Panels

- Facing: CFRT (Continuous fiber reinforced thermoplastic) sheet.

- Core: Polypropylene honeycomb.

- Manufacturing Process: Thermoplastic composite.

Its facing material is CFRT, which has higher strength than GRP. CFRT and PP are composited using a thermoplastic compounding process to make their combination closer and stronger.

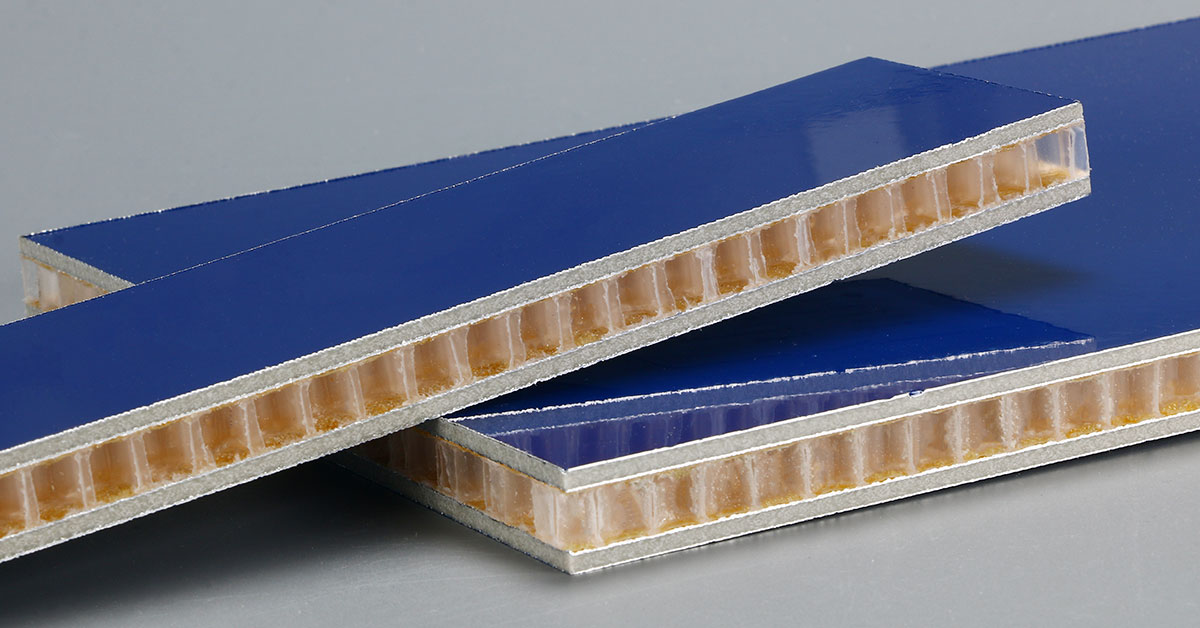

ACP Facing PP Honeycomb Sandwich Panels

- Facing: Aluminum composite panel.

- Core: Polypropylene honeycomb.

- Manufacturing Process: Press laminates composite.

Aluminum composite panels are corrosion-resistant, lightweight, high-strength, and flame-retardant. It is a decorative panel used in many industries.

Industries We Serve

The application of polypropylene honeycomb sandwich panels not only provides more stable performance for the final application product, but also reduces the cost of project implementation, bringing real cost reduction and efficiency improvement. Especially on RVs, box trucks, boats, mobile buildings and other projects that need to reduce weight and strengthen the structure.

Custom Polypropylene Honeycomb Sandwich Panels for Your Projects

We can meet customers’ unique performance requirements for polypropylene honeycomb panels. We provide a series of solutions and develop new applicable honeycomb composite panels.

We have thermoplastic composite and press composite production lines to meet customer needs for PP honeycomb sandwich panels with different properties.