Our Factory

•Professional •Advanced •Large-scale

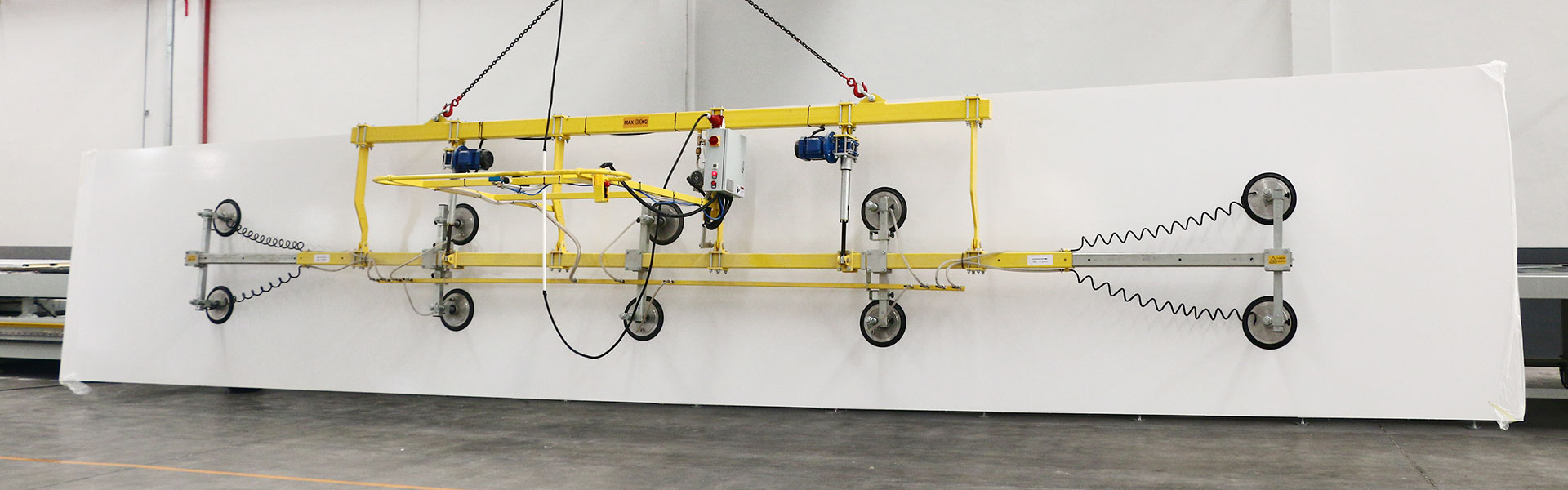

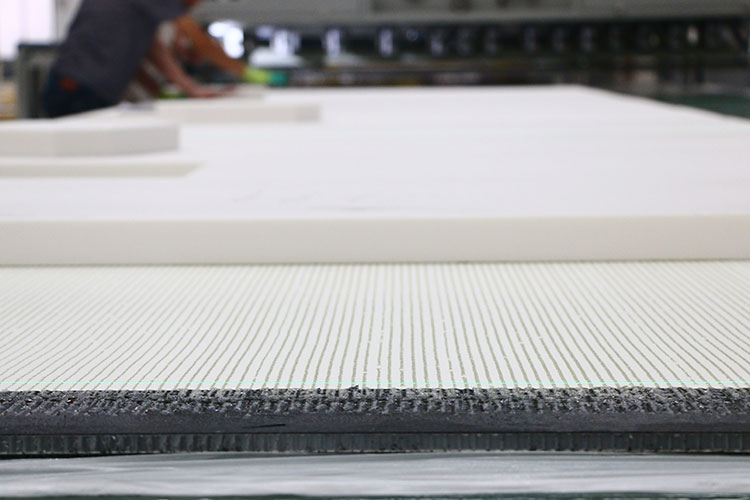

Composite Panel Production Line

Independently developed and efficient production equipment:: fast, efficient and precise. Our factory has advanced manufacturing technology and production machines, and professional workers carry out customized production. We are equipped with highly automated production equipment such as constant temperature and humidity test chambers, automatic glue pouring machines, and efficient press machines.

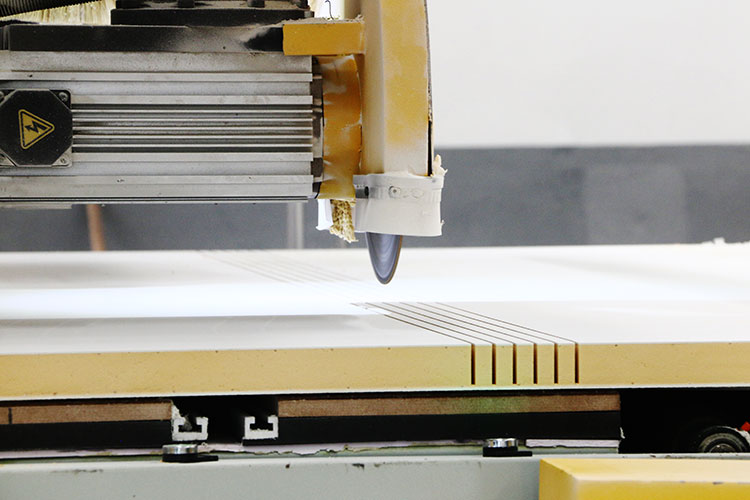

CNC Machining

5-axis CNC machining: cutting, drilling, milling. Our factory has a strict quality control system. We ensure that all products produced have passed quality inspections to minimize errors.

Performance Testing

Our performance includes: tensile, compressive, peeling, high temperature resistance, low temperature resistance and other tests. (Products can be tested in the range of -60~150℃.) We strictly implement each inspection process to ensure that the products delivered to customers are 100% qualified.

Packaging & Transportation

Customized packaging solution: Engineers make corresponding packaging designs based on the performance of the product. Both the packaging and the container have undergone motion analysis, and some packages have even undergone finite element analysis. We also conducted loading and unloading simulations to ensure the safety of the goods during transportation.