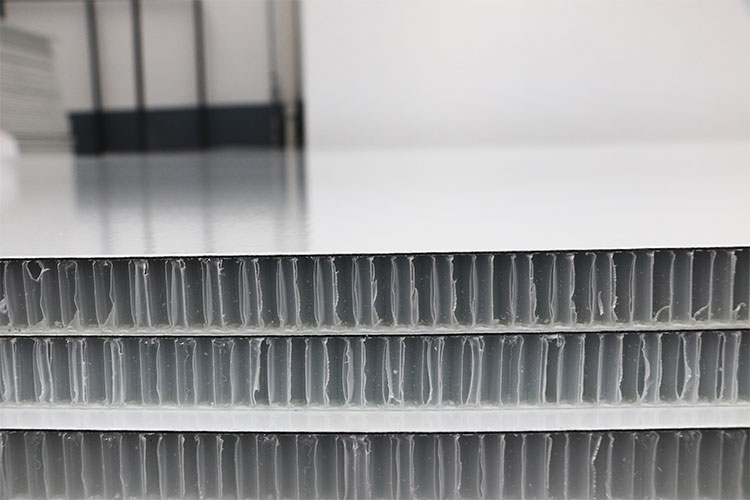

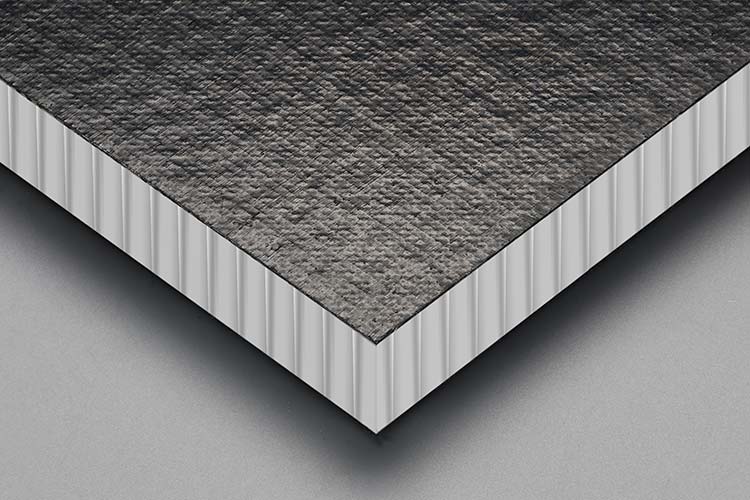

Thermoplastic honeycomb panels are sandwich-structured panels whose skins are composed of CFRT (continuous fiberglass thermoplastic) sheets and the middle layer structure is a polypropylene honeycomb core. Unlike the adhesive process, thermoplastic honeycomb panels are processed by thermal fusion lamination (by heating the materials to fuse them). Since no glue is used during processing, the bonding between the layers is more precise and the sandwich structure is more stable and reliable.

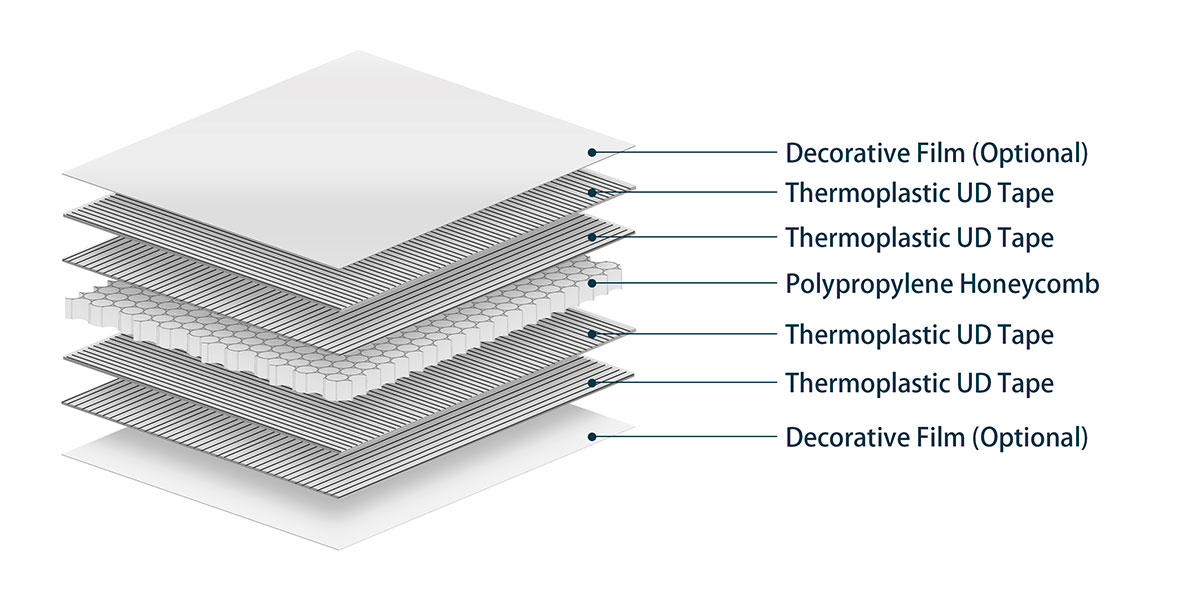

Structure Schematic

- Decorative Film: The decorative film not only has an aesthetic effect, but also plays a waterproof role. You can choose PET, PVC, PP and other materials as the decorative film, and you can also print patterns on the film.

- Thermoplastic UD Tapes: UD tapes are interwoven at different angles (usually 0 °/90 °), and the number of layers of UD Tapes varies from 2 to 10 layers according to the strength requirements. The more layers of the unidirectional tape, the higher the strength of the thermoplastic honeycomb panel.

- Polypropylene Honeycomb: The honeycomb core provides a stable structural support for the composite panel. The diameter of the PP honeycomb core cells ranges from 8mm to 12mm, and the most commonly used ones are 8mm, 10mm, and 12mm, which can be made according to customer requirements.

Basic Specifications

- Skin material: CFRT (Continuous Fiberglass Thermoplastic) sheet. (Thickness: 0.4~2.5mm)

- Core material: Polypropylene Honeycomb. (Cell diameter: 80/120mm)

- Length: Within 12m.

- Width: Within 3.2m.

- Thickness: 6.0~120mm.

Thermoplastic Honeycomb Panel VS Plywood VS Aluminum Panel

| Items | Aluminum Panel | Plywood | Thermoplastic Honeycomb Panel |

| Corrosion Resistance | Not easily corroded | Easily corroded | Not easily corroded |

| Waterproof | Not waterproof | Not waterproof | Waterproof |

| Electrical Insulation | Conductive | Non-conductive | Non-conductive |

| Heat Insulation | Poor | Normal | Good |

| Cutting performance | Not easy to cut | Easy to cut | Easy to cut |

| Strength | Poor strength | poor strength | High strength |

| Price | High | Low | Low |

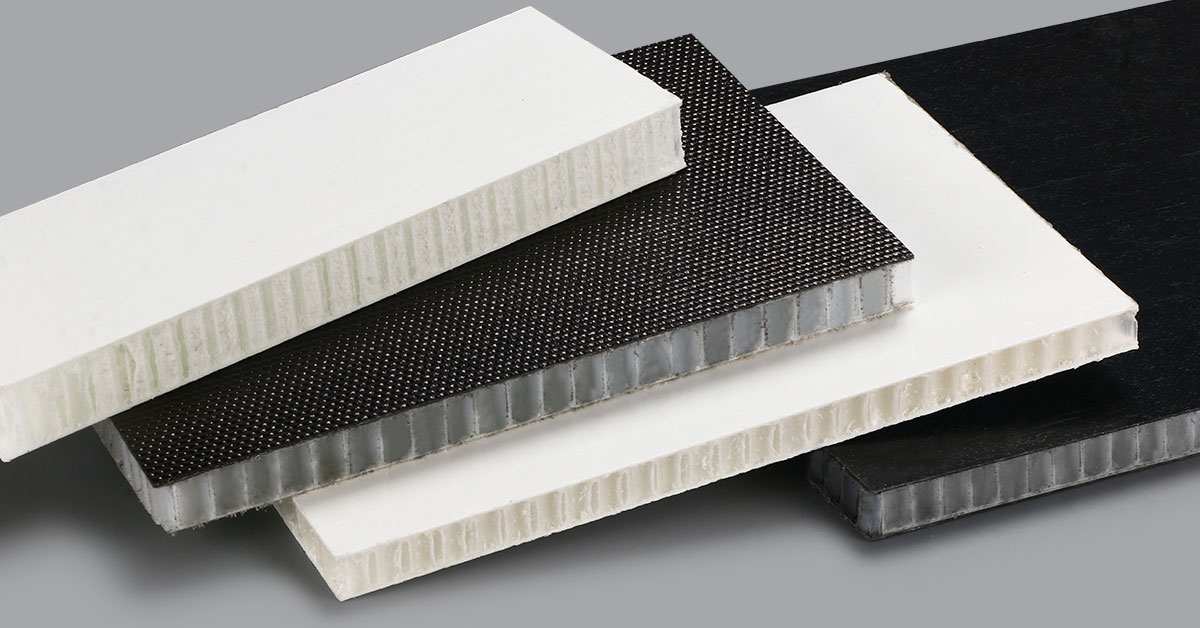

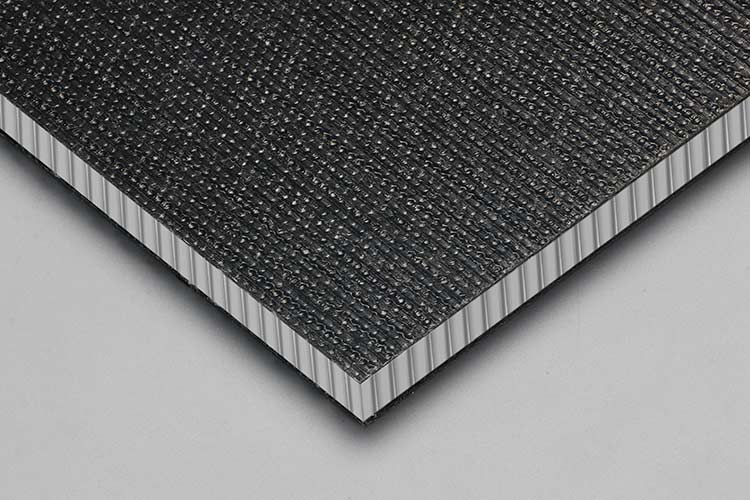

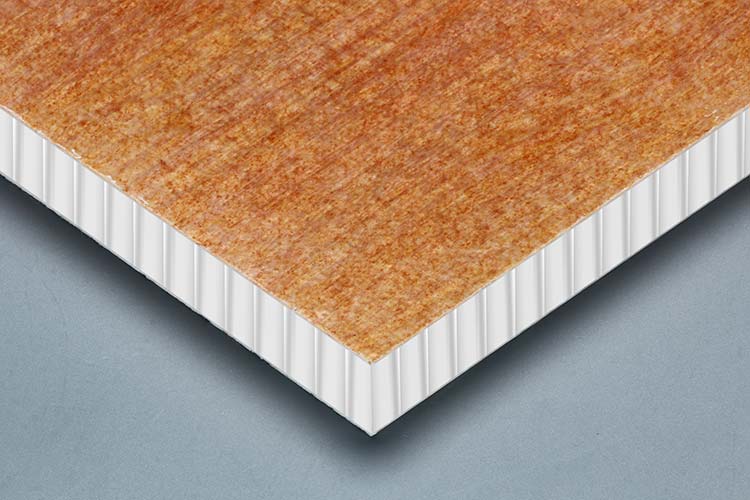

Surface Treatment

We provide a variety of surface treatments for thermoplastic PP honeycomb panels to meet different application requirements, such as UV resistance, anti-skid, lamination, spray painting, etc.

Application Field

Thermoplastic honeycomb panels are widely used in the field of construction, including building exterior wall finishes, interior decoration, partition walls, ceilings, floors, sound insulation panels, etc. It is also used in the field of packaging, such as boxes, trays, protective packaging, etc. In addition, it is used as an interior trim panel in vehicle manufacturing.

We Are a Professional Thermoplastic Honeycomb Panel Manufacturer

We have an advanced fully automatic thermoplastic honeycomb panel production line, which is currently the largest and most technologically advanced production line in China.

- Fast and efficient: The annual output of thermoplastic composite panels can meet the manufacturing needs of 80,000 boxes.

- High precision and error-free: the absolute error is within 1.0mm.

Beyond Ordinary Quality