GRP PU sandwich panel is a lightweight composite panel with good thermal insulation properties and other comprehensive properties. It is one of the most popular PU panels currently.

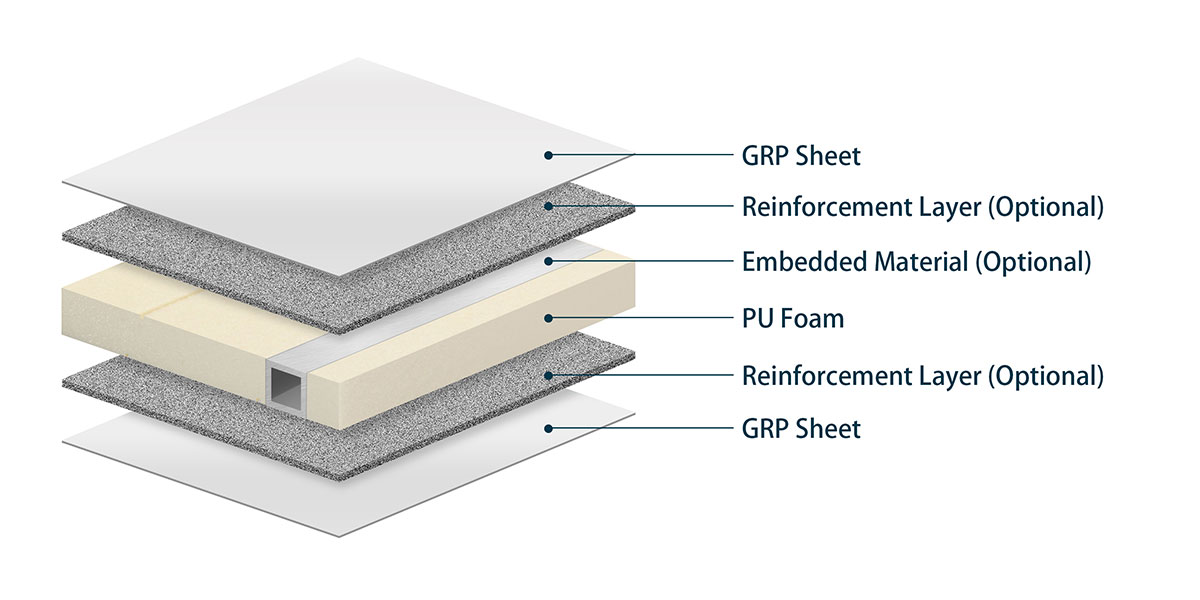

Basic Structure

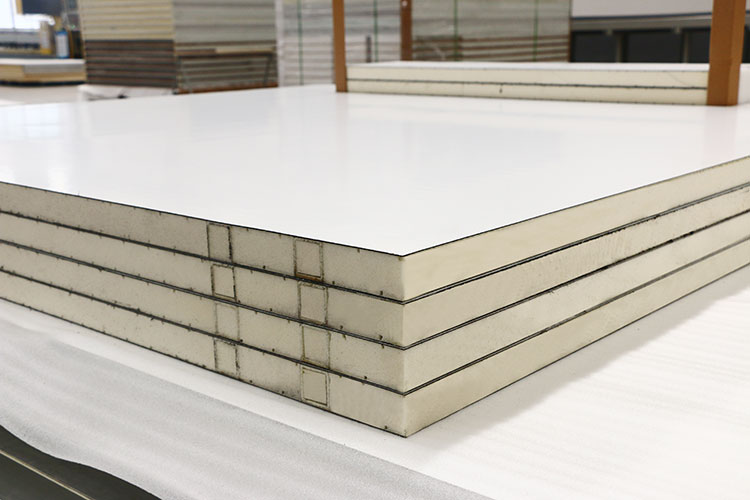

Basic Specifications

- Skin Materials: Gelcoat flat GRP sheet, CFRT sheet.

- Core Materials: PU foam core.

- Performance Rreatment: anti-ultraviolet, flame retardant, antistatic.

- Length: ≤12m.

- Width: ≤3.2m.

- Total Thickness: Customized.

- Process Options: Embedded reinforcement materials; CNC machining services.

Types of GRP Sheets

In addition to thermosetting GRP materials, we have also developed a new type of thermoplastic resin GRP material – CFRT (continuous fiber reinforced thermoplastic) as the skin material. The combination of thermoplastic resin and continuous glass fiber makes CFRT more impact-resistant, compressive-resistant, and flexural-resistant.

Advantages and Applications

- Excellent thermal insulation properties: Polyurethane foam has excellent thermal insulation properties, not only insulating heat but also providing good acoustic insulation. This makes GRP PU foam sandwich panels very useful in applications requiring insulation such as construction, refrigeration equipment and refrigerated vehicles.

- Lightweight but High Strength: Although very light, fiberglass PU foam sandwich panels have excellent strength and can withstand a certain amount of impact and pressure. This makes it ideal for projects that require structural support and protection.

- Excellent corrosion resistance: The outer layer of GRP has excellent corrosion resistance, making it less susceptible to erosion by water, acid, alkali and other chemicals. This makes it more durable for use in harsh environmental conditions.

- Easy to process: GRP PU foam sandwich panels are relatively easy to process and customize, and can be cut, shaped and connected according to specific needs. This reduces construction costs and time.

- Weather Resistance: The GRP outer layer can withstand UV rays and climate changes and is not prone to fading, aging or deformation, making it ideal for outdoor applications.