PET (Polyethylene Terephthalate) foam board. It is made by mixing PET resin with foaming agent, and then processed through extrusion, foaming and calendaring. The rigid PET foam board used on the composite panel is harder and denser.

Characteristics of PET Foam Board

- Rigid Characteristics

Compared with other foam materials, PET foam board is harder and denser. It usually won’t bend or deform as easily as regular Styrofoam. - High Density

Its higher density makes it more suitable for applications requiring higher strength and stiffness. - Thermal Insulation Properties

Like other foam materials, PET foam board also has good insulating properties and is suitable for thermal and acoustic insulation applications. - Recyclability

PET foam is recyclable, which is good for the environment.

Performance of PET Foam Board

| Item | Standard | Unit | Value | T-core 80 | T-core 100 | T-core 120 | T-core 150 | T-core 200 | T-core 250 |

| Density | ISO845 | Kg/m3 | Test Average | 80 85-95 | 100 100-110 | 120 120-130 | 150 150-160 | 200 190-210 | 245 235-260 |

| Compressive Strength | ISO844 | MPa | Average Medium | 0.85 0.80 | 1.20 1.10 | 1.80 1.55 | 2.40 2.20 | 3.90 3.40 | 5.20 4.80 |

| Compressive Modulus | ISO844 | MPa | Average Medium | 73 65 | 100 90 | 115 105 | 140 125 | 200 170 | 235 210 |

| Tensile Strength | ASTM-C297 | MPa | Average Medium | 1.40 1.30 | 1.80 1.60 | 2.20 1.90 | 2.50 2.20 | 3.2 2.6 | 4.0 3.6 |

| Tensile Modulus | ASTM-C297 | MPa | Average Medium | 90 80 | 110 100 | 120 105 | 160 130 | 210 180 | 275 250 |

| Shear Strength | ISO192-2-2012 | MPa | Average Medium | 0.55 0.45 | 0.80 0.75 | 0.90 0.80 | 1.25 1.05 | 1.70 1.50 | 2.05 1.80 |

| Shear Modulus Parallel to the bonding line Perpendicular to the bonding line | ISO192-2-2012 | MPa | Average Average Medium | 13.5 12.5 10.0 | 23.0 21.0 19.0 | 27.0 23.0 21.0 | 35.0 30.0 26.0 | 51.0 47.0 43.0 | 70.0 65.0 60.0 |

| Climbing Drum Peel (once a year) | ASTM-D1781 | mm*N/m | Average | 20 | 20 | 20 | 20 | 20 | 20 |

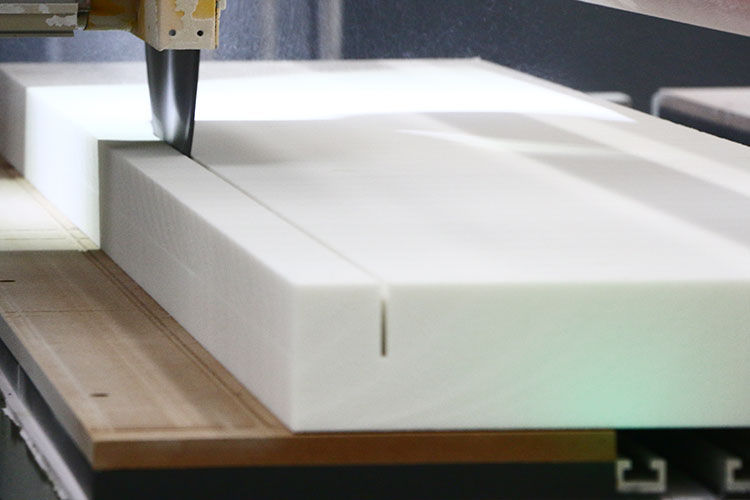

Processing of PET Foam Board

PET foam has excellent properties of being easily cut to fit different shapes and sizes. For example, the foam can be cut into sheets, blocks, or custom shapes.