ACP facing foam sandwich panels are a new type of composite structural material, which combines the advantages of aluminum composite panels and rigid foam.

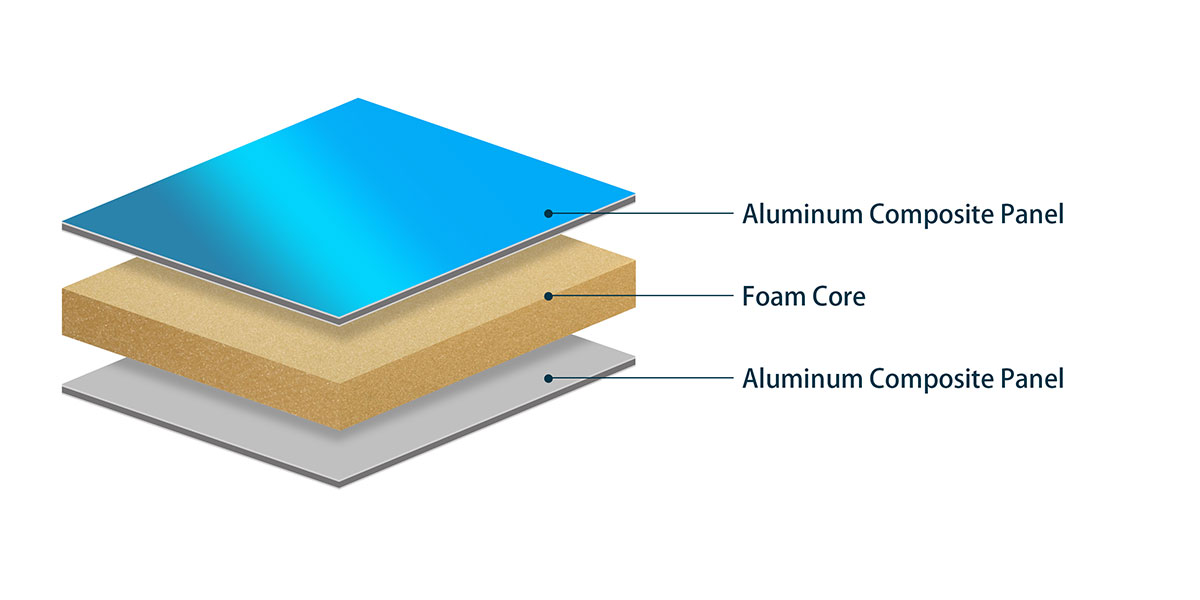

The Schematic of Structures

- ACP Surface Layer

ACP (Aluminum Composite Panel) is a multi-layer structure material, which is made of polyethylene material sandwiched between two layers of aluminum sheets. It is light, strong, highly decorative and easy to process. - Core Materials

Generally, choose rigid foam with high compressive strength such as XPS/PET/PU/PVC. These foams maintain the lightweight properties of the panels.

Basic Specifications

- Skin material: Aluminum Composite Panels.

- Core material: XPS/PET/PU/PU/PVC foam board.

- Length: 2440mm.

- Width: 1220mm.

- Total Thickness: 5.0~120mm.

Applications

- Building Exterior Wall

It is used for the decoration of the exterior wall of the building, providing a colorful decorative effect for the building. - Advertising

It is widely used for billboards due to its lightness, ease of processing and flat surface. - Interior Decoration

It can be used for interior decoration, including making walls, ceilings, cabinets, furniture. - Refrigeration Equipment

ACP faced foam sandwich panels are used to maintain low-temperature environments in the manufacture of refrigerated vehicles, cold storage and freezing equipment. - Boxes

Due to its high strength and light weight, it can make various boxes, such as dry cargo truck boxes, air transport boxes, etc.