GRP PET sandwich panel is a multi-functional composite material with the characteristics of lightweight, high strength, corrosion resistance and thermal insulation properties.

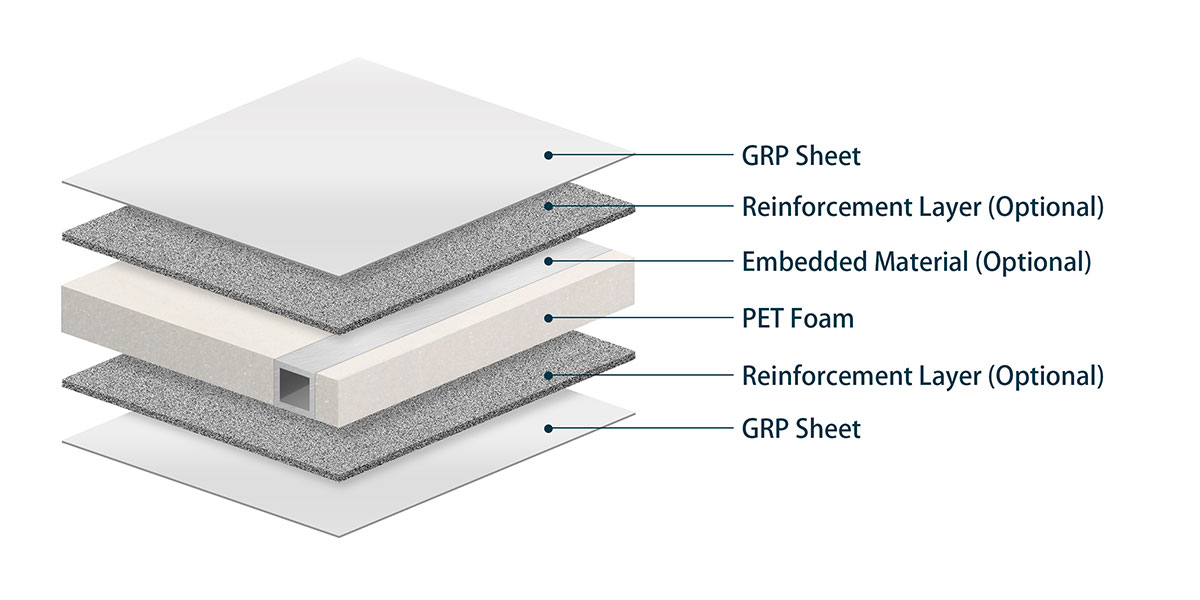

Schematic

Basic Specifications

- Skin Materials: Gelcoat flat GRP sheet, CFRT sheet.

- Core Materials: PET foam core.

- Performance Rreatment: anti-ultraviolet, flame retardant, antistatic.

- Length: ≤12m.

- Width: ≤3.2m.

- Total Thickness: Customized.

- Process Options: CNC machining services.

Types of GRP Sheets

In addition to thermosetting GRP materials, we have also developed a new type of thermoplastic resin GRP material – CFRT (continuous fiber reinforced thermoplastic) as the skin material. The combination of thermoplastic resin and continuous glass fiber makes CFRT more impact-resistant, compressive-resistant, and flexural-resistant.

Advantages and Applications

GRP PET foam sandwich panel has many advantages which make it popular in various applications.

- Lightweight: It is very light and has a low density compared to other materials, making it suitable for projects that require weight reduction, such as ships, cars, and aircraft.

- High Strength: Despite being lightweight, GRP PET foam sandwich panels have excellent strength and are able to withstand a degree of impact and pressure, making them useful in structural support and protection applications.

- Corrosion Resistance: GRP materials have excellent corrosion resistance and are not easily eroded by water, acid, alkali and other chemicals. This makes it ideal for use in harsh environmental conditions.

- Insulating Properties: It excels in insulating properties and can effectively isolate heat and electricity. This makes it widely used for insulation purposes in construction, refrigeration equipment and electrical equipment.

- Ease of Processing: GRP PET foam sandwich panels are relatively easy to process and customize, and can be cut, shaped and connected according to specific needs. This improves its suitability for a variety of applications.

- Environmental Protection: PET is a recyclable material, so the waste generated during the production and processing of GRP PET foam sandwich panels can be recycled and reused, helping to reduce environmental impact.

- Weather Resistance: Fiberglass PET foam sandwich panels perform well in outdoor environments, have good UV and weather resistance, and are not easy to fade or age.