Product Specifications

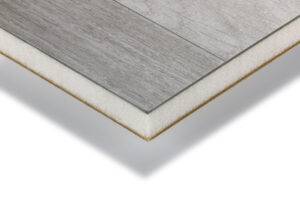

- Total Thickness: 20.0mm. (Customized: 10~120mm)

- Size: 1220x2240mm or customized.

- Top Facing: 1.0mm wood grain HPL film + 3.0mm plywood.

- Core Layer: 12.0mm 100kg/m³ PET foam. (Customized: 60~300kg/m³)

- Bottom Facing: 1.0mm HPL film + 3.0mm plywood.

- Area Weight: 7.1kg/m².

- Applications: Door panels, wall cabinets, bed panels, partitions, etc.

Description

HPL Plywood

HPL plywood, the full name of high pressure laminated plywood, is a composite material commonly used in decoration and construction. HPL is the abbreviation of High-Pressure Laminate in English, which means high-pressure laminate. This material is usually made of multi-layer kraft paper impregnated with phenolic resin and then pressed under high temperature and pressure, and attached to the surface of the base material (such as plywood), thereby forming a board that is both beautiful and decorative and has good physical properties.

PET Foam

PET foam, or polyethylene terephthalate foam, is a multifunctional, high-performance material that is widely used in various industries due to its excellent balance of properties. It is known for its strength, durability and recyclability.

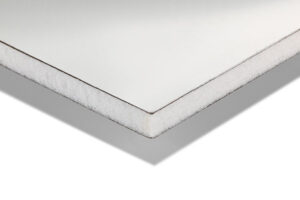

Schematic Diagram

Product Advantages

- Wear and scratch resistant.

- Diverse appearance.

- Fire retardant.

- Easy to clean.

- Lightweight and high strength.

- Sound insulation.

Applications

Due to its excellent performance and beautiful appearance, HPL plywood facing PET foam sandwich panel is widely used in the following fields:

- Interior decoration: walls, ceilings, partitions, etc.

- Furniture manufacturing: such as cabinets, wardrobes, desks, etc.

- Commercial space: interior walls and furniture in public places such as shopping malls, hospitals, office buildings, etc.

- Transportation: such as interior decoration of trains, ships, and airplanes.