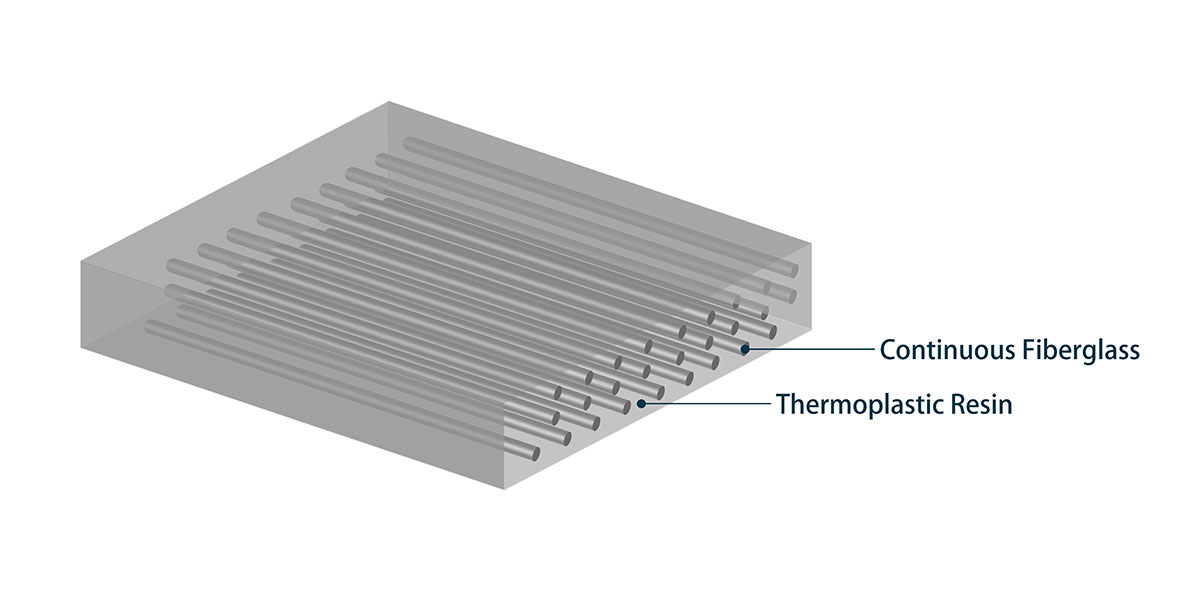

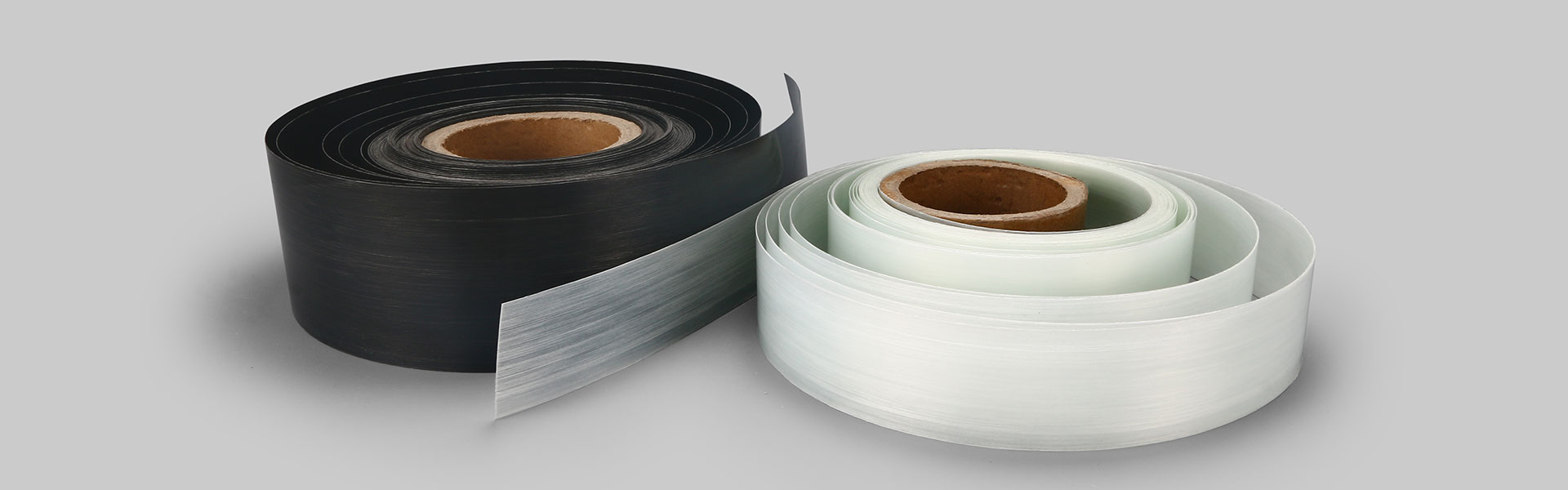

Continuous fiberglass thermoplastic UD tape is a new type of structural composite material, which is made of continuous fiberglass impregnated with thermoplastic resin, which is often used to enhance the performance of structures. It has a series of advantages such as lightweight, high strength, and corrosion resistance, and is widely used On laminated sheets, winding pipes, molded products and other products. Also, compared to thermoset prepregs, thermoplastic prepregs are stable at room temperature and generally have no shelf life.

Cross-sectional Structural Diagram

Continuous fiberglass is a high-performance fiber material with a continuous filamentary structure. These filamentous fibers have various characteristics such as lightweight, high strength, and corrosion resistance.

Advantages of Continuous Fiberglass

The performance of continuous fiber-reinforced thermoplastic composite materials is very excellent. The longer the fiber length, the better the mechanical properties. Its specific strength can be more than 10 times that of ordinary steel. (The higher the specific strength, the lighter the material used to achieve the corresponding strength.) Therefore, continuous fiber-reinforced thermoplastic composite materials can realize lightweight applications in which plastic replaces steel.

Basic Specifications

- Thickness: 0.15~0.45mm.

- Width:300~1200mm.

- Resin: Polypropylene (PP), polyethylene (PE), nylon (PA), polyphenylene sulfide (PPS), etc.

- Fiber: Fiberglass.

- Production Method: melt impregnation.

- Area weight: 150~300gsm.

- Fiber Content: 40~75%.

Performance Parameter

| Typical Product | Density(g/cm3) | E-Glass Fiber Content | Thickness(mm) | Areal Weight(g/m2) | Tensile Strength(MPa) | Tensile Modules(GPa) | Color |

| UD-PP-300-60 | 1.5 | 60% | 0.2 | 300 | 800 | 28 | Natural or Black |

| UD-PP-370-60 | 1.5 | 60% | 0.25 | 370 | 850 | 28 | Natural or Black |

| UD-PP-450-60 | 1.5 | 60% | 0.3 | 450 | 900 | 30 | Natural or Black |

| UD-PE-450-65 | 1.6 | 65% | 0.3 | 450 | 850 | 30 | Natural or Black |

| UD-PE-500-70 | 1.7 | 70% | 0.35 | 500 | 900 | 30 | Natural or Black |

| UD-KPP-450-60 | 1.5 | 60% | 0.3 | 450 | 750 | 28 | Natural or Black |

| UD-ZRPP-450-60 | 1.5 | 60% | 0.3 | 450 | 700 | 28 | Natural or Black |

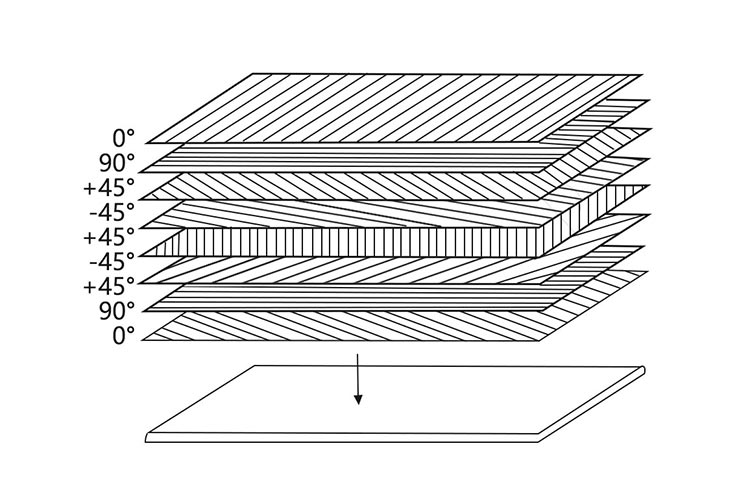

Laying Angles of Thermoplastic UD Tape

- 0°: This layup consists of fibers aligned parallel to the loading direction. It has high stiffness and strength in the load direction.

- 0°/90°: This type of layup consists of two layers, one with fibers aligned in the 0° direction and the other with fibers aligned in the 90° direction. It provides good shear properties and is commonly used in applications where support of in-plane and out-of-plane loads is required.

- +45°/−45°: This type of layup consists of two layers, one with fibers aligned at an angle of ±45°. It provides balanced in-plane properties.

Custom Thermoplastic UD Tapes

We have advanced thermoplastic unidirectional tape production equipment and can customize continuous fiber products of different specifications according to your project.

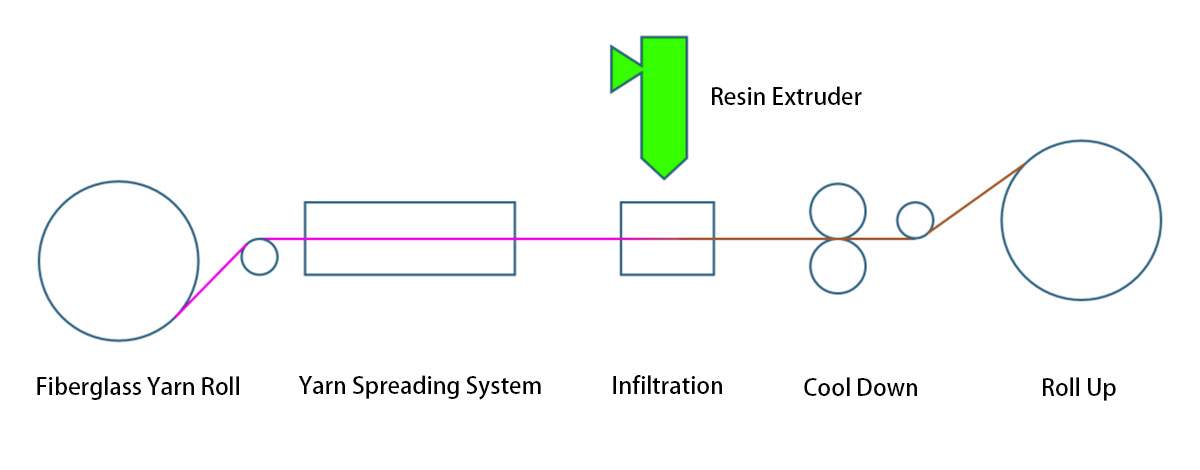

Production Process of Thermoplastic UD Tapes

After the fiber drawn out from the yarn spreading system comes into contact with the high-temperature thermoplastic resin extruded from the impregnation die device, the fiber and resin are compounded into a composite material with a certain thickness and surface through processes such as heating, impregnation, pressurization, cooling, slitting, and winding. Smooth thermoplastic prepreg unidirectional tape.

Application Fields of Thermoplastic UD Tape

Aerospace: Thermoplastic UD tapes are used in aerospace applications due to their high strength to weight ratio. They are commonly used to strengthen aircraft components such as wings, fuselage and engine parts.

Automotive: In the automotive industry, thermoplastic UD tapes are used to reduce vehicle weight while maintaining structural integrity. They are used in components such as body, chassis and interior trim.

Sporting Goods: Thermoplastic UD tapes are used in the manufacture of sporting goods such as tennis rackets, golf clubs, bicycle frames and snowboards where light weight and high strength are essential.

Wind Energy: Wind turbine blades are reinforced with thermoplastic UD tape to increase their stiffness and durability, allowing them to withstand harsh environmental conditions.

Ships: In shipbuilding and marine applications, thermoplastic UD tapes are used in hulls, decks and other structural components to reduce weight and improve performance.

Pipes: Reinforced thermoplastic pipes are widely used in the transmission of oil and natural gas.

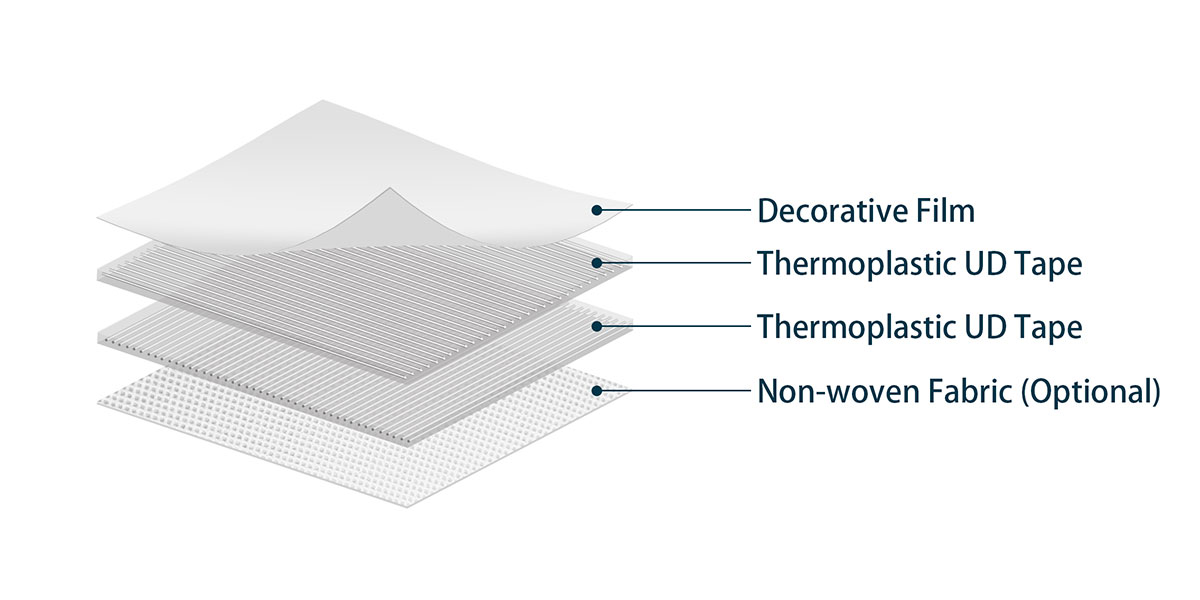

Continuous Fiberglass Thermoplastic Composite Sheets – CFRT Sheets

The continuous glass fiber thermoplastic composite sheet is made of unidirectional prepreg tapes at different angles and with different numbers of layers, which are thermally laminated by a composite machine. It has high strength, high rigidity, and low density, and can be used to replace aluminum sheets, steel sheets, plywood, thermosetting GRP and other materials, and is used as a skin material for box trucks, container lining panels, building formworks, and sports equipment. In addition, the thickness, weight and strength of the composite sheet can be customized according to customer needs, such as anti-ultraviolet protective film, non-woven layer, anti-slip layer, and decorative layer can be added.