XPS (Extruded Polystyrene, XPS is a closed-cell rigid insulating material. It is currently the most popular thermal insulation core material in construction, vehicles and other fields.

Features of XPS Foam Board

- Good heat insulation performance

XPS is a closed-cell structure with low thermal conductivity, which can effectively heat preservation and heat insulation. - High compressive resistance

XPS is harder and has high compressive strength, making it less likely to deform when subjected to heavy pressure. - Good waterproof performance

XPS is not hydrophilic, even if soaked in water for a long time, it will not rot. - High stability

Our XPS foam board does not deform in the temperature range of -20~70°C.

Properties of XPS Foam Board

| Item | Reference | Unit | Value |

| Density | / | kg/m3 | 30~50 |

| Fire Rate | / | / | B2 |

| Water Absorption Rate | / | % | ≤1.5 |

| Thermal Conductivity | Average 25℃ | W/M·K | ≤0.026 |

| Tensile Strength | 75mm to 100mm thick | KPa | ≥600 to 800 |

| Compression Strength | Post-production 7 to 15 days storage | KPa | 350/360 to 380 |

| Splice Clearance | / | mm | ≤1 |

| Size Stability | -20℃ (40H) to 70±2℃ (48H) | % | ≤2 |

| Length Tolerance | Reserved for transportation loss | cm | 2 to 3cm |

| Width Tolerance | mm | ±2 | |

| Thickness Tolerance | Same batch Between batches | mm | ±0.4 ±0.5 |

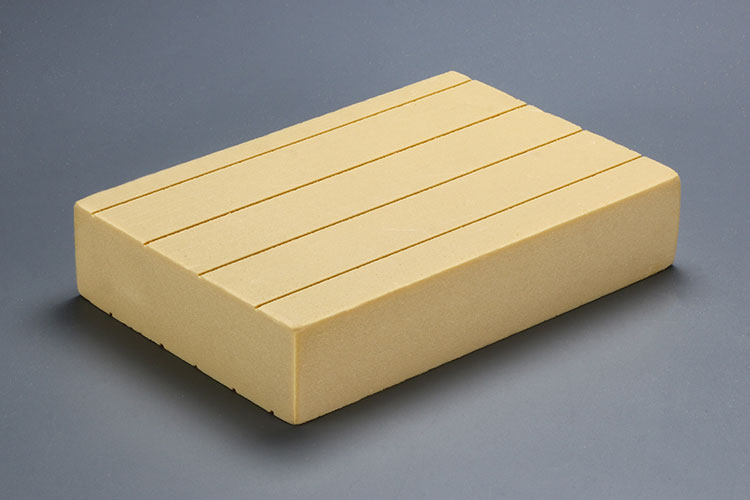

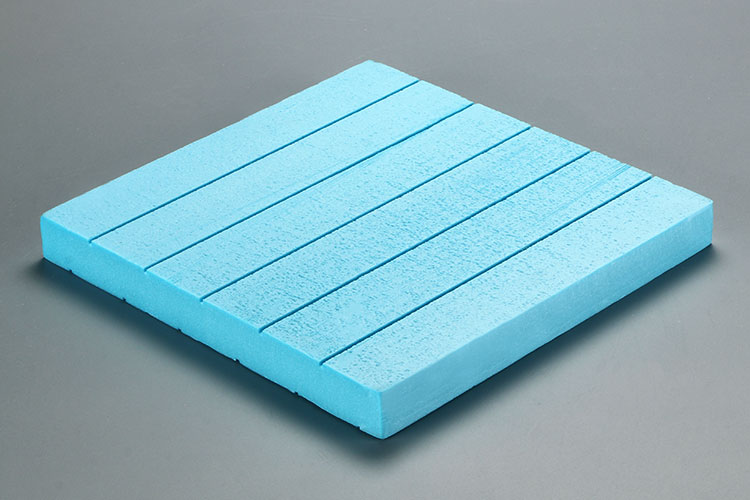

XPS Foam Board Colors

The colors of XPS foam boards include yellow, white, blue, green, red, etc. Different colors of foam are due to different color masterbatches added. The quality of XPS foam can be judged by color. The color of high-quality foam board is bright, while the color of inferior extruded board will be dull because of its impure texture. The XPS foam boards we produce have stable performance, uniform color, and no impurities.

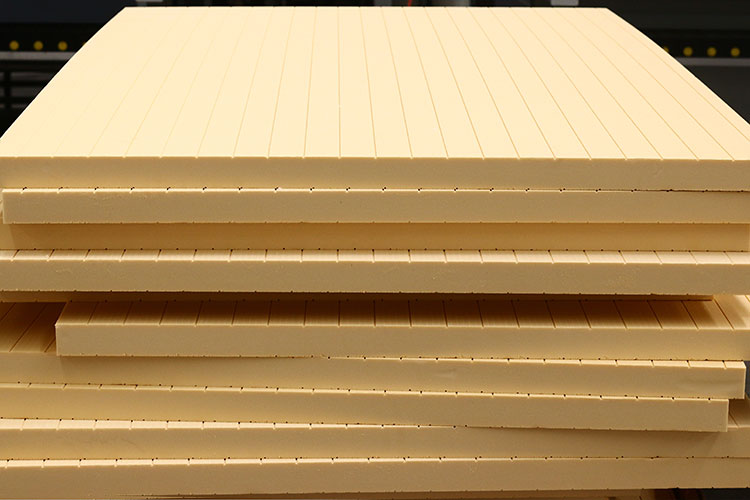

Machining of XPS Foam

According to customer needs, we use high-precision and efficient CNC processing to process foam boards into various shapes and sizes.

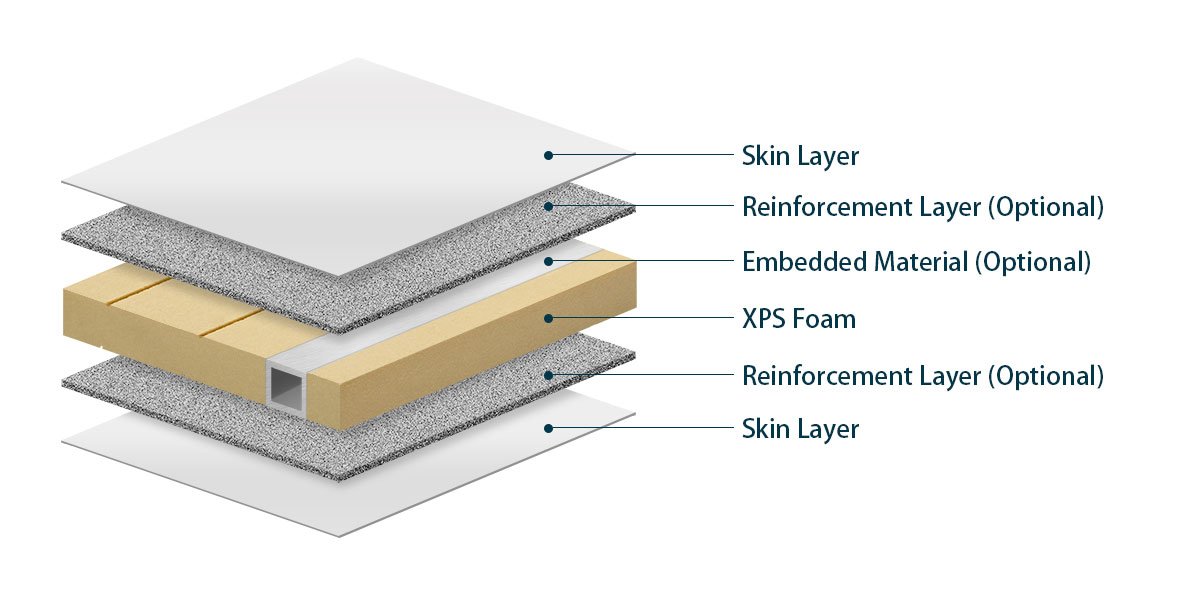

XPS Sandwich Panels

By using adhesives, XPS foam can be laminated with a variety of material systems to form thermally insulating, lightweight and strong sandwich panels. According to different application purposes, GRP (glass fiber reinforced plastic), aluminum, stainless steel, galvanized steel, PVC board, plywood, MDF (medium density fiberboard), etc. can be selected as the outer skin material.