Composite Panel Production Line

•High Efficiency •High Precision •High Quality

Advanced Production Equipment

Fully automatic cutting machine

The operator does not need to touch the skin material, which avoids damage to the skin surface and reduces the adhesion of oil stains, thus improving the adhesion between the skin and the core material, and making the composite panel very smooth. It is also a detection platform that can directly detect whether the skin material meets production requirements.

Highly flat positioning platform

The highly flat positioning platform can quickly assemble embedded parts. The accuracy error of embedded parts is within 0.2 mm, and the panels produced are very flat. It is also a platform for testing the flatness and defects of the core material. This platform is particularly suitable for manufacturing composite panels that require reinforcement materials to be embedded inside, such as RVs, refrigerated trucks, dry trucks, mobile homes, etc.

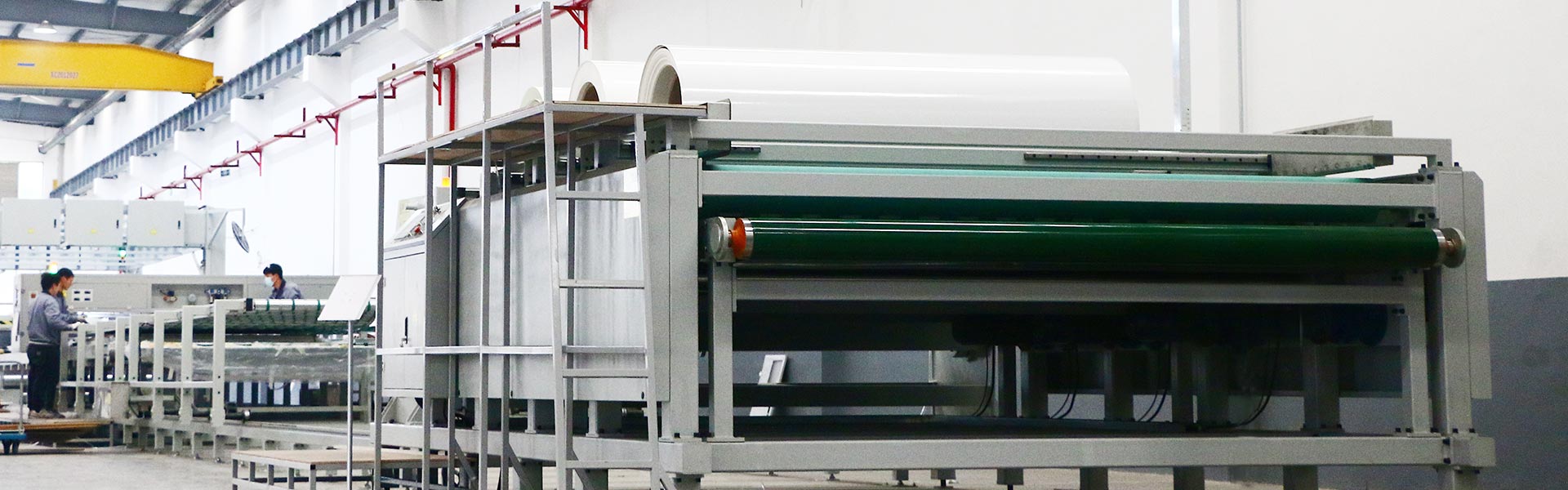

Fully automatic glue laminating machine

The glue spraying machine can choose different glues according to different materials. The system is equipped with an advanced coating control system that can achieve precise coating thickness and coating position, and evenly spray the adhesive on the surface of the core material. The spray width can be adjusted arbitrarily to meet the production of panels of different sizes, and the glue spray width can be adjusted according to the width of different sizes.

Multi-layer vacuum press

This is a customized positive and negative integrated multi-layer press developed by TOPOLO. It adopts automotive grade standards and has uniform pressure. The surface of the pressed composite panel is very smooth, which can avoid problems such as delamination and bulging. Its production efficiency is very high, and it can press more than 100 square meters of composite panels at the same time, and the pressing time can be shortened to 30 minutes.

Large vacuum suction cup spreader

The lifting capacity of the suction cup spreader is up to 2 tons. Using the suction cup spreader can not only quickly transport the composite panels, but also avoid panel damage and protect the edges and surfaces of the panels.

Quality inspection system

We conduct a series of performance checks for composite panels: pressure resistance test, peeling test, high temperature resistance test, corrosion resistance test, UV resistance test, etc. Only composite panels that meet quality inspection standards can be sent to users.

Customized Composite Panels

Due to the use of glue as the binding agent, the choice of core and skin materials is very wide. In general, all rigid foams can be used as core materials and are compatible with skins of any material. In addition, honeycomb core and plywood can also be selected as core materials.

(”√”It means that the skin and core materials are compatible with each other and can be well bonded together.)

| Core Materials/Skin Materials | FRP | CFRT | Aluminum | Stainless Steel | GI(Galvanized) Steel | GL(Galvalume) Steel | Plywood | PVC Sheet | HPL Sheet |

| XPS Foam | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| PET Foam | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| PVC Foam | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| PU Foam | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| PMI Foam | √ | √ | √ | √ | √ | √ | √ | √ | √ |

| PP Honeycomb | √ | √ | |||||||

| Aluminum Honeycomb | √ | √ | √ | √ | |||||

| Plywood | √ | √ | √ | √ | √ | √ | √ | √ |