- High Strength

- Lightweight

- Corrosion Resistant

- Smooth

- Thermal Insulation

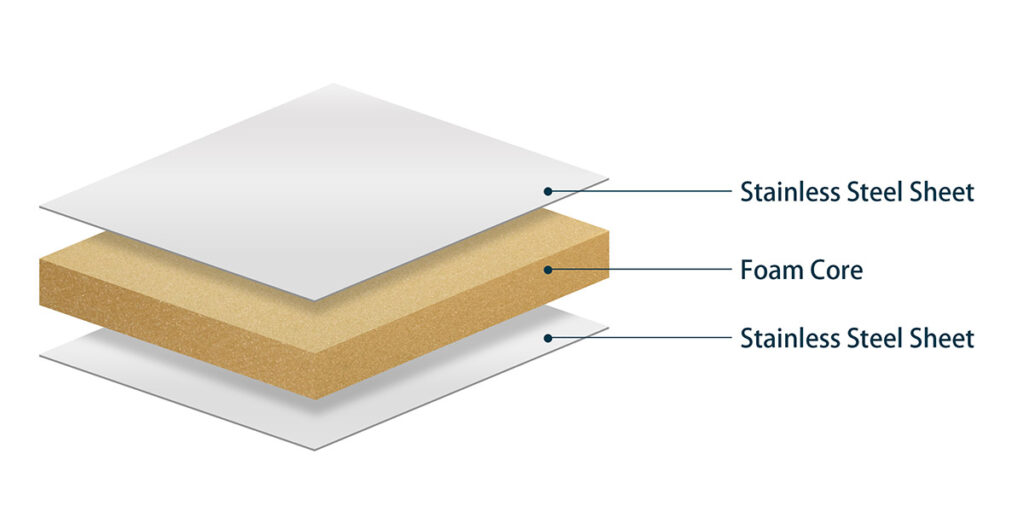

Foam core stainless steel sandwich panels apply the high strength of stainless steel and the lightweight properties of foam core materials. This is a composite material whose comprehensive performance far exceeds that of other metal sandwich panels. Stainless steel as a skin material makes up for many shortcomings of galvanized steel sheets and aluminum sheets.

The advantages of stainless steel skin are reflected in:

- Will not rust: Stainless steel has added chromium, which makes it resistant to corrosion by acid, alkali, and salt media.

- High strength: Stainless steel has excellent fatigue resistance and high toughness. It can still maintain its shape after being rolled and unfolded.

- Wear resistance: The surface of stainless steel has a high-hardness wear-resistant layer, which makes it not as fragile as aluminum, and ordinary collisions will not leave scratches on its surface.

- Smooth surface: The brightness of stainless steel is the highest among existing metal skin materials, and most stainless steel sheets have high-quality mirror-like surfaces.

Basic Specifications

- Width: ≤1.50 mm.

- Length: ≤12 mm.

- Total Thickness: 10~120 mm.

- Stainless Steel Sheet Thickness: 0.4-3.0 mm.

- Stainless Steel Grade: SS201, SS 304.

- Core Material: XPS, PU, PET, PVC, PMI foam, etc.

One Piece Laminated Composite Panels

Stainless steel foam core sandwich panels are produced using adhesive composite lamination. Compared with injection molded sandwich panels, the core material and skin are more closely combined. This one-piece composite panel has a flatter surface and higher strength, and the panel size can be customized according to project needs.

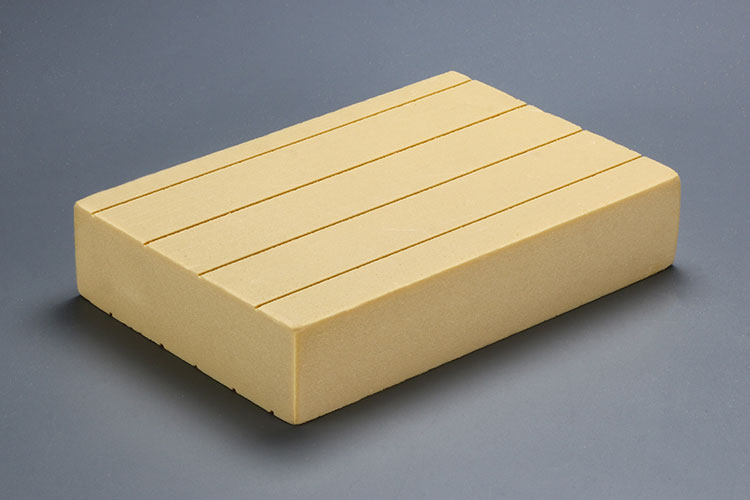

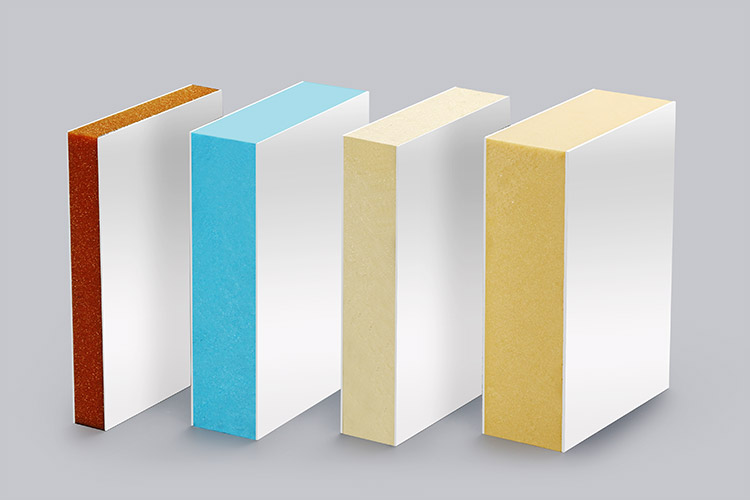

Diverse Foam Core Materials

Stainless steel sheets can be compounded with a variety of foam core systems after treatment and show good performance stability. Rigid closed-cell foams are the most commonly used lightweight core materials, and they provide both adequate compressive strength and high thermal insulation properties. These foams include XPS(Extruded Polystyrene), PU (polyurethane), PET (Polyethylene Terephthalate), PVC (Polyvinyl Chloride), PMI (Polymethacrylimide), etc.

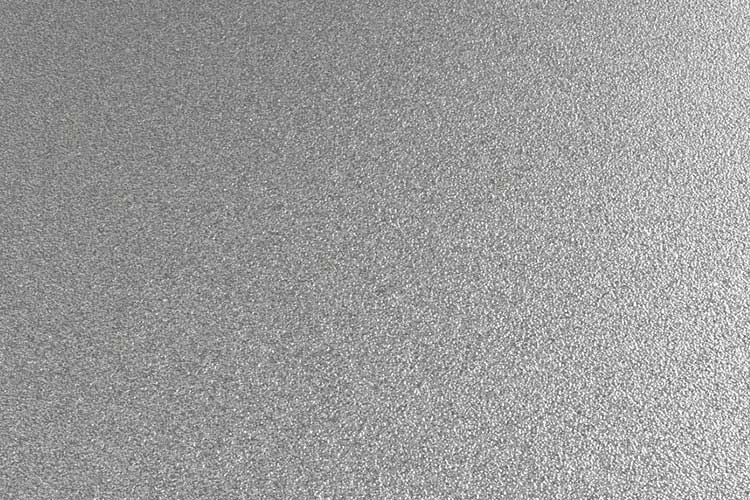

Stainless Steel Surface Treatment

To bring more visual effects, various treatments are required on the stainless steel surface, including polishing, frosting, brushing, titanium plating, embossing, etc.

Application of Stainless Steel Sandwich Panels

Stainless steel sandwich panels are widely used in projects with high requirements such as construction, vehicles, and industry.

Building Walls

Due to the corrosion resistance and aesthetics of stainless steel, stainless steel sandwich panels can be used as exterior wall materials for high-end building projects.

Cold Rooms

PU/XPS sandwich panels have excellent thermal insulation properties and can effectively maintain the internal temperature of the box.

Interior Decoration

Due to the appearance and easy cleaning properties of stainless steel, stainless steel sandwich panels also have certain applications in decoration and interior design, such as for walls, ceilings, etc.

Refrigerated Trucks

The refrigerated body made of stainless steel sandwich panels is strong, durable and easy to clean. Suitable for transporting meats, poultry, aquatic products, etc.