PP hollow plastic formwork is a material used in building construction. It is made of polypropylene (PP) material and has excellent properties such as lightweight, high strength, and weather resistance. It is an energy-saving and environmentally friendly product. It is a new product after wooden formwork, steel formwork and aluminum alloy formwork.

PP Hollow Plastic Formwork Does Not Require Release Agents

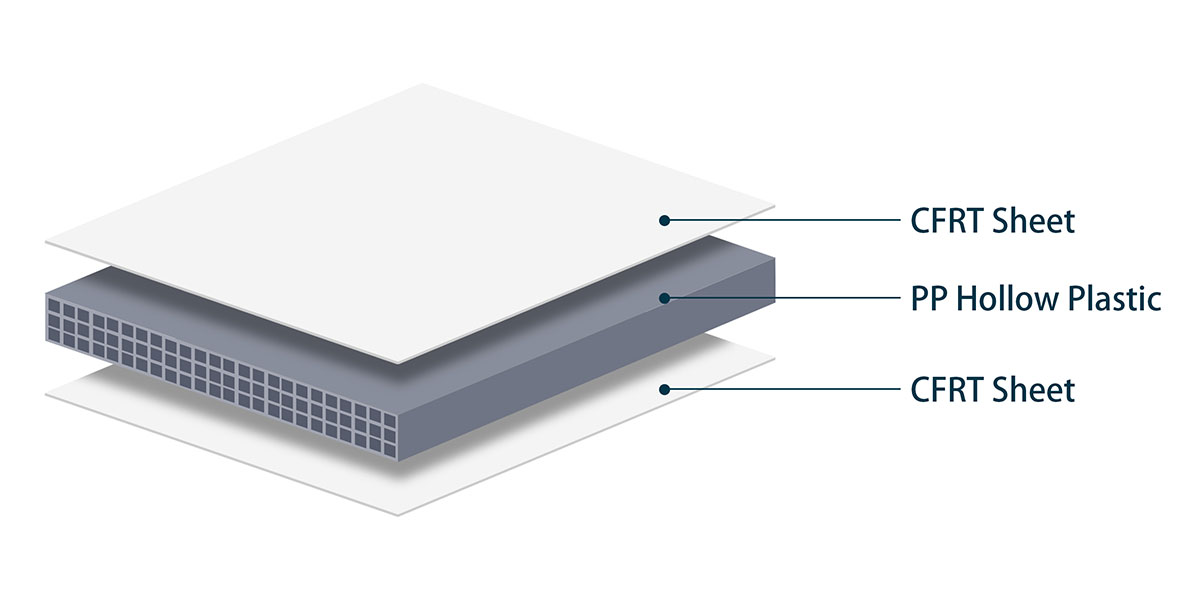

Using CFRT coatings instead of release agents can increase product recovery rates. Our new PP (polypropylene) hollow plastic formwork is a composite product of CFRT (continuous fiber reinforced thermoplastic composite) sheet material and polypropylene hollow plastic, which is processed using a thermoplastic lamination composite process. The CFRT sheet is tightly fused with the PP hollow plastic.

Specifications

- Total Thickness: 13mm, 14mm, 15mm, 18mm, 20mm or customized.

- CFRT Thickness:0.44~2.0mm.

- Size: 1220mmx2440mm or customized.

- Hollow Size:4x4mm.

- Density: 0.5g~1.0g/cm³.

- Color: Usually black/green for the core and white/black for the skin.

- Flammability: Grade B2(E).

Schematic Diagram

- CFRT Sheets

CFRT (continuous fiber reinforced thermoplastic) sheet is made of multiple layers of thermoplastic unidirectional tape laid at different angles. It has excellent performance in rigidity and wear resistance. More

- PP Hollow Plastic

Its main component is the polymer material polypropylene resin. It is made by physically modifying the polypropylene and mixing it with a variety of additives to change the chemical molecular structure, and then through the extrusion production process.

Performance Parameters

| Properties | Unit | Standards | Value |

| Thickness | mm | 15mm | |

| Grammage | Kg/m2 | / | 10 |

| Water Absorption | % | GB/T 1462 | 0.26 |

| Shore D. Hardness | / | GB/T 2411-2008 | 69 |

| Flexural Strength | MPa | JGT418-2013 | 61 |

| Flexural Modulus | MPa | JGT418-2013 | 4935 |

| Non-notched Impact Strength | KJ/m2 | GB/T 1451-2005 | 60 |

| Heat Expansion | % | JGT418-2013 | ±0.13 |

| VST Point | ℃ | GB/T 8626-2007 | B2(E) |

| Min. Working Temperature | ℃ | / | -20 |

Advantages of CFRT Skin PP Hollow Plastic Formwork

- Longer Service Life

PP hollow plastic formwork can be reused more often after adding CFRT sheets. Ordinary PP hollow plastic formwork can be reused about 50 times, but CFRT skin PP hollow plastic formwork can be reused more than 100 times.

- Better Waterproof Effect

CFRT sheet provides a waterproof and chemical-resistant layer for the hollow plastic formwork, effectively reducing cement corrosion on the formwork.

- Higher Stiffness

After adding CFRT sheets, the machine strength of the hollow plastic formwork is greatly improved, the structure is more stable, and problems such as expansion and deformation of the formwork can be avoided.

- Dimensional Stability

Under weather conditions of high temperature, low temperature and high humidity, the expansion rate is extremely low and it is not easy to deform. However, traditional wooden formwork obviously cannot do this.

- Easier to Release

The smooth surface of the CFRT sheet makes it difficult for cement and other impurities to adhere, and there is no need to apply a release agent, so the formwork is easier to disassemble after the construction is completed.

- 100% Recyclable

The matrix of CFRT and PP is both thermoplastic. If the formwork is damaged, it can be 100% recycled, thereby reducing waste pollution to the environment.

Performance Comparison

| Items/Materials | Unit | Bamboo/Wood | Aluminum | TOPOLO PP |

| Times Reusable | times | 5 to 8 | 100 | ≥100 |

| Fireproof | / | NO | YES | YES |

| Recyclable | / | NO | YES | YES |

| Moisture Deforming | / | Easy | Uneasy | Uneasy |

| Demould | / | Uneasy | Uneasy | Easy |

| Release Agent | / | Required | Required | Unrequired |

| Dust Removing | / | Required | Unrequired | Unrequired |

| Unit Labor Cost | / | High | Low | Low |

| Shape Customizing | / | Available | Must | Available |

| Corrosion Resistant | / | ★ | ★★★ | ★★★★★ |

| Sun Resistant | / | NO | YES | YES |

| Burst and Leakage | / | Possible | Impossible | Impossible |

| Onsite Remould | / | Easy | Uneasy | Easy |

Applications in The Construction Industry

After the concrete pouring is completed and the formwork is removed, the surface of the rammed body will be smooth without plastering. It is especially suitable for the construction of high-rise buildings, stairs, basements, and bridge piers for highways and railways.