Thermosetting fiberglass sheets are composite material composed of glass fiber and thermosetting resin, usually, we call it GRP.

What Thermosetting Resin?

Thermoset resins are a special type of resin that chemically reacts when heated, becoming hard and irreversible. Unlike thermoplastic resins, thermoset resins do not soften or melt again once hardened, giving them excellent stability and durability in high-temperature environments.

What is fiberglass?

Fiberglass is made by drawing molten glass into filaments and then subjecting these filaments to special treatments. This treatment enhances the fiber’s strength, durability and other properties.

Feature of GRP Sheets

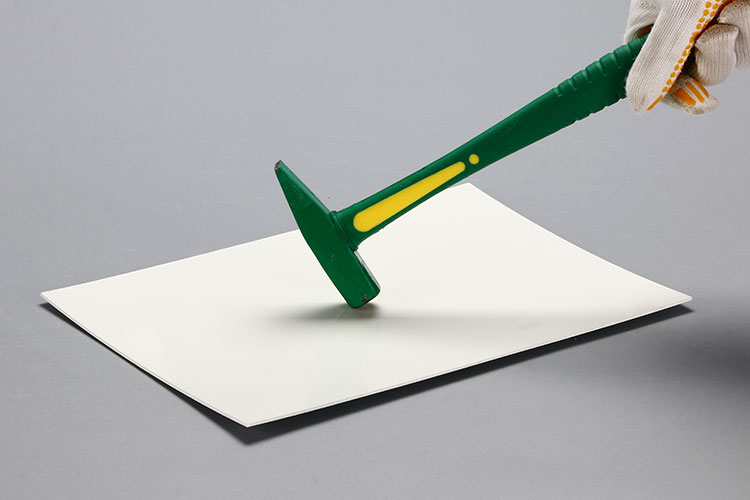

- Lightweight and high strength: GRP is relatively lightweight but has high strength. This makes them ideal for replacing metals.

- Corrosion Resistance: It has high resistance to water, chemicals and most corrosive substances.

- Insulating properties: It has good insulating properties, preventing current leakage or other electrical problems.

- Wear Resistance: It has excellent wear resistance and is able to withstand long-term use and friction, reducing damage and maintenance needs.

- Weather resistance: It has good UV resistance and is not easily affected by the sun’s rays. They are also resistant to extreme climate changes and are suitable for outdoor environments.

Basic Specification of GRP Sheets

- Resin Type: Unsaturated Polyester Resin; Epoxy Resin; Phenolic Resin.

- Fiberglass Type: Fiberglass Mat; Fiberglass Cloth.

- Fiberglass Content: 40~70%.

- Thickness: 0.7~5.0mm.

- Width: ≤3.2m.

- Length: 100~400m/roll.

- Surface Treatment: glossy, matte, embossed, etc.

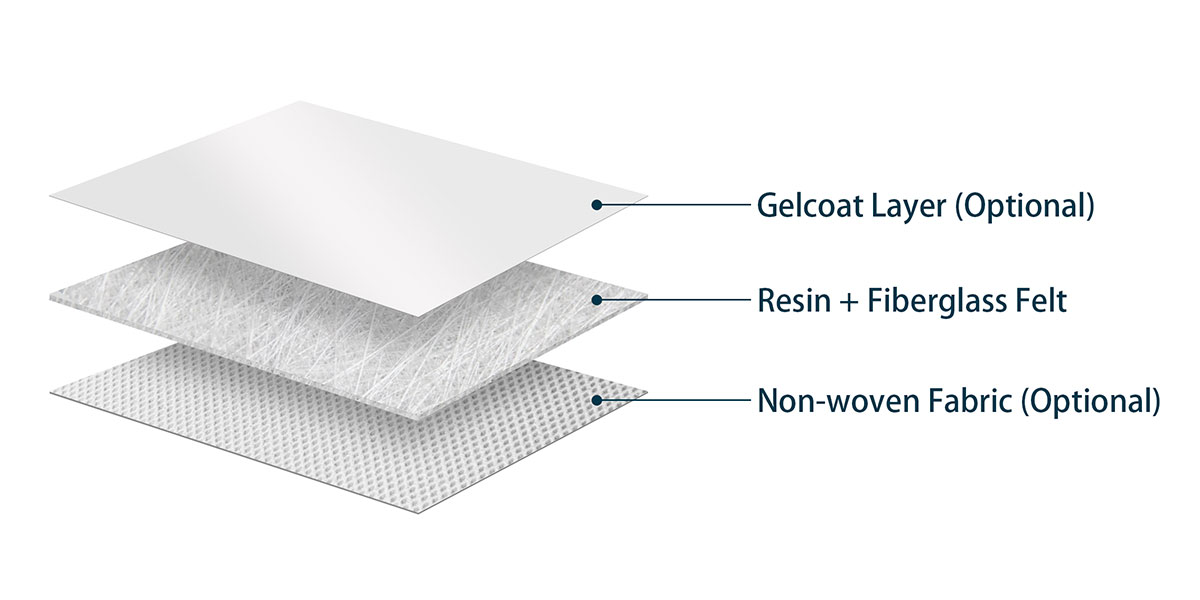

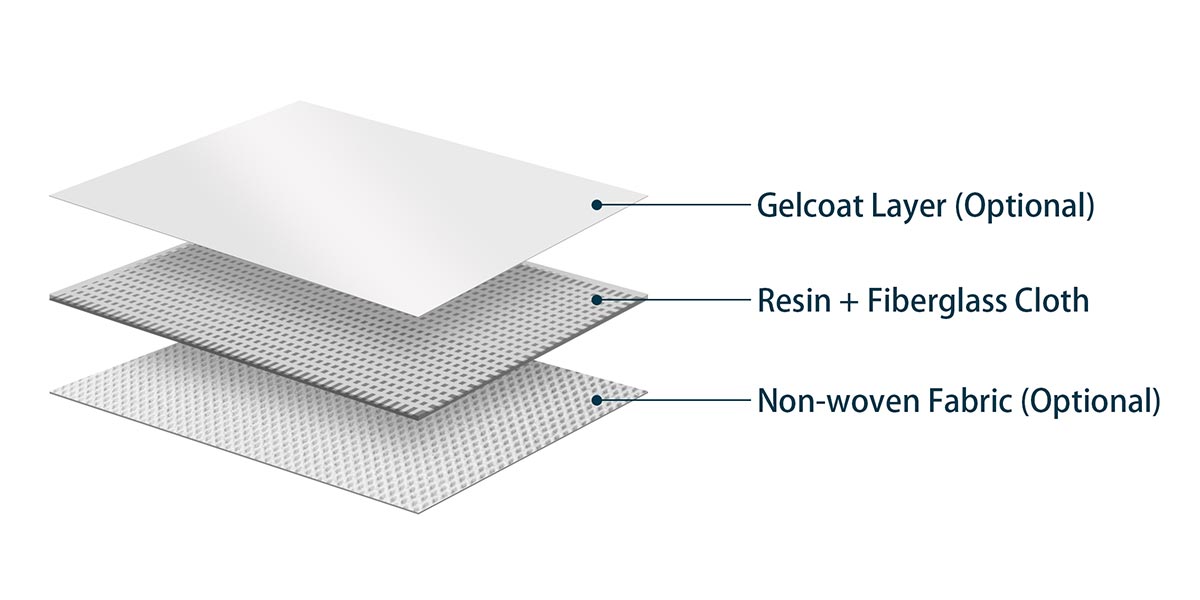

Types of Fiberglass

Usually, the fibersglass in GRP sheets are in the form of felt or fabric.

We customize GRP sheets with and without gelcoat.

Gelcoat GRP Sheets

The gel coat can prevent the glass fiber texture from being highlighted due to shrinkage after the resin is cured, improve the smoothness of the surface, make the surface look aesthetic, and play the role of waterproofing, moisture-proof, and UV resistance.

None Gelcoat GRP Sheets

Usually, GRP sheets without gelcoat protection are for better lamination with other materials.

Our Quality Commitment

- There is no deviation in the thickness and width of GRP sheets.

- The surface of GRP is flat and smooth, with uniform texture and no color deviation.

- Long term outdoor use, its surface does not fade, turn yellow, or become brittle, with a service life of more than 10 years.

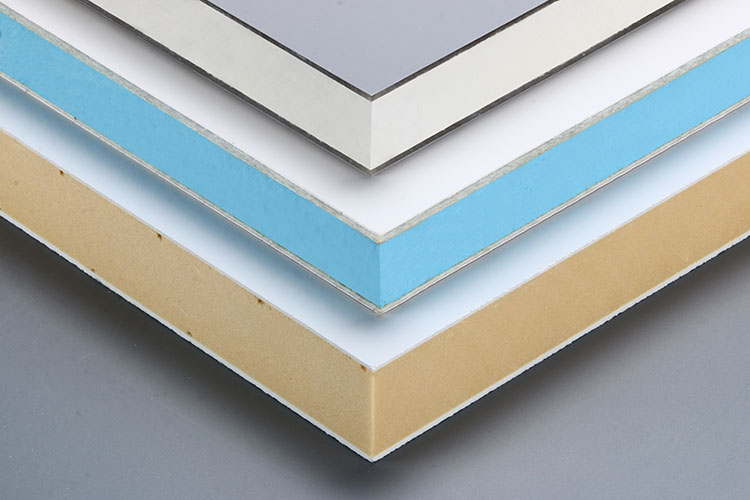

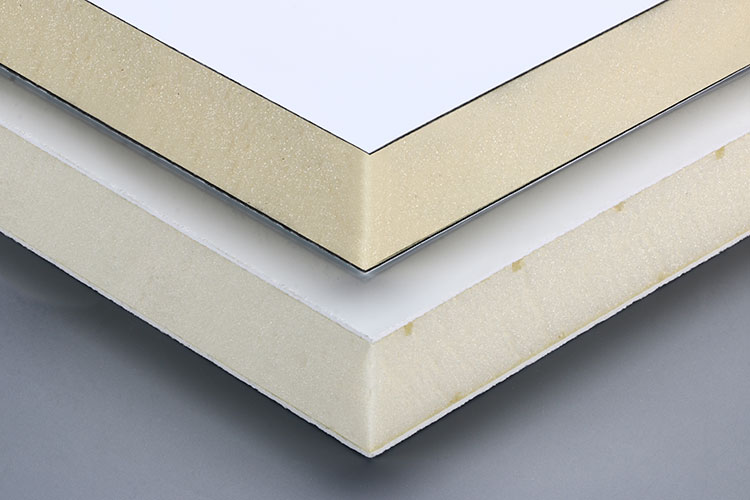

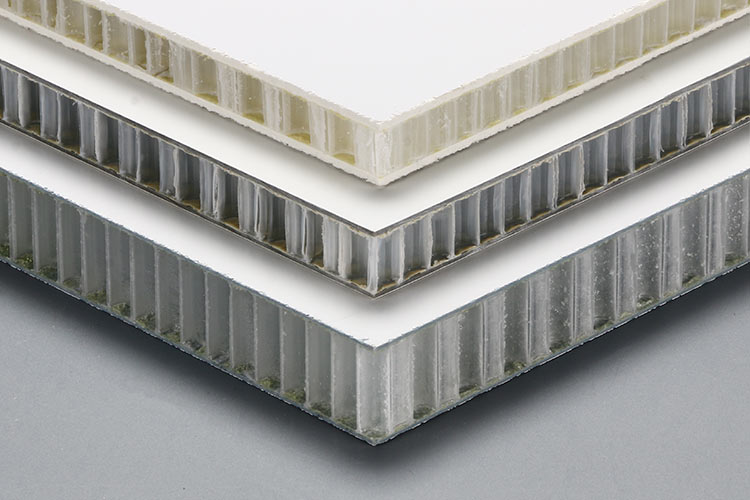

GRP Sandwich Panels

GRP sheet is a high-quality skin material used in sandwich panels. It is compatible with various core material systems, such as foam, PP honeycomb, plywood, etc. GRP sandwich panels have replaced wood boards and metal sheets in many fields, achieving product lightweight, aesthetics and longer service life. These composite panels are widely used in fields such as RVs, trucks, buildings, vessels, etc.