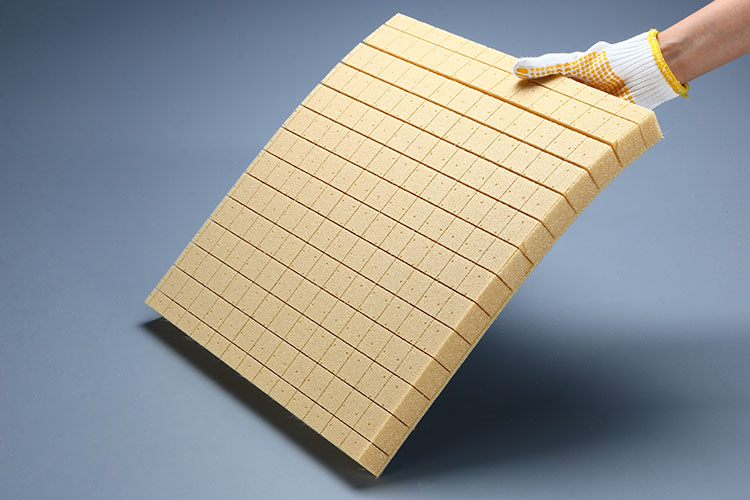

PVC (polyvinyl chloride) foam, by adding a blowing agent to create a foam structure.

It has a series of advantages:

- Lightweight: PVC foam is very light and has excellent specific strength.

- Insulation Properties: It acts as a good heat insulator.

- Weather Resistant: It is highly resistant to UV rays and most chemicals, making it suitable for outdoor applications.

- Easy Processing: PVC foam is easy to cut, shape and bond, and can be made into various shapes and structures according to needs.

- Sound Insulation Performance: The cell structure of PVC foam helps to reduce sound transmission, so it is often used in sound insulation materials to reduce noise.

- Water Resistance: It has some water resistance, so it is suitable for use in wet environments.

Performance of PVC Foam

| Test Items | Test Standards | Unit | Typical Value | PVC40 | PVC48 | PVC55 | PVC75 | PVC90 | PVC130 | PVC200 | PVC250 |

| Density | ISO 845 | Kg/m3 | Average Range | 40 | 48 43-55 | 60 54-69 | 80 72-92 | 100 90115 | 130 120150 | 200 180250 | 250 225288 |

| Compression Strength | ISO 844 | N/mm2 | Average Minimum | 0.45 | 0.60 1.50 | 0.90 0.75 | 1.45 1.10 | 2.0 1.7 | 3.0 2.6 | 5.2 4.5 | 6.6 5.3 |

| Compression Modulus | DIN 53421 | N/mm2 | Average Minimum | 41 | 48 35 | 69 55 | 104 80 | 130 110 | 170 145 | 280 240 | 350 280 |

| Tensile Strength | ISO 527 1-2 | N/mm2 | Average Minimum | 0.7 | 0.95 0.8 | 1.3 1.0 | 2.0 1.6 | 2.7 2.2 | 4.0 3.0 | 6.0 4.8 | 7.5 5.5 |

| Tensile Modulus | ISO 527 1-2 | N/mm2 | Average Minimum | 28 | 35 28 | 45 35 | 66 50 | 84 65 | 115 95 | 175 140 | 230 160 |

| Shearing Strength | ISO 1922 | N/mm2 | Average Minimum | 0.45 | 0.55 0.5 | 0.85 0.7 | 1.2 1.0 | 1.7 1.4 | 2.4 2.1 | 3.5 3.2 | 4.7 3.8 |

| Shearing Modulus | ASTM C393 | N/mm2 | Average Minimum | 13 | 16 14 | 22 18 | 30 24 | 40 34 | 54 45 | 75 68 | 95 78 |

| Elongation at Break | ISO 1922 | % | Average Minimum | 8 | 10 8 | 16 10 | 18 10 | 23 12 | 30 20 | 30 20 | 30 20 |

| Thermal Conductivity at Room Temperature | ISO 8301 | W/m.k | Average | 0.031 | 0.031 | 0.031 | 0.033 | 0.035 | 0.039 | 0.048 | 0.056 |

Application of PVC Foam

- Building and construction industry: PVC foam panels are commonly used in the building and construction industry for insulation, thermal insulation and sound insulation. They can be used as wall insulation, roof insulation, floor insulation and more, helping to improve the energy efficiency of buildings.

- Advertising and Decoration: PVC foam boards are often used in billboards, signs, exhibitions and decorative materials because of their lightweight and easy-to-process properties. They can be cut, engraved and printed for use in a variety of interior and exterior decorating projects.

- Transportation: PVC foam is used in aircraft, trains and automotive interiors such as seats, siding and ceilings to reduce weight and provide sound and thermal insulation.

- Packaging: PVC foam can be used as packaging material to protect fragile items. They have good cushioning properties which reduce the risk of damage during transport.

- Arts and Crafts: PVC foam board can be used for a variety of arts and crafts projects such as model making, sculpting, painting and modeling.

- Water activities: Floating devices and snorkeling gear made of PVC foam are very popular because they are lightweight, water and corrosion resistant, and provide buoyancy.

- Medical field: PVC foam is used in the medical field to make medical equipment, mattresses and mattress coverings because of its easy cleaning and antibacterial properties.

- Toys: Children’s toys, such as buoys, floats, swimming rings and various game devices.