Plywood facing foam sandwich panels combine the characteristics of plywood and foam, maintaining their lightness while maintaining strength. Compared with pure plywood, its weight is greatly reduced, and it maintains the characteristics of easy cutting and high nail-catching force of plywood.

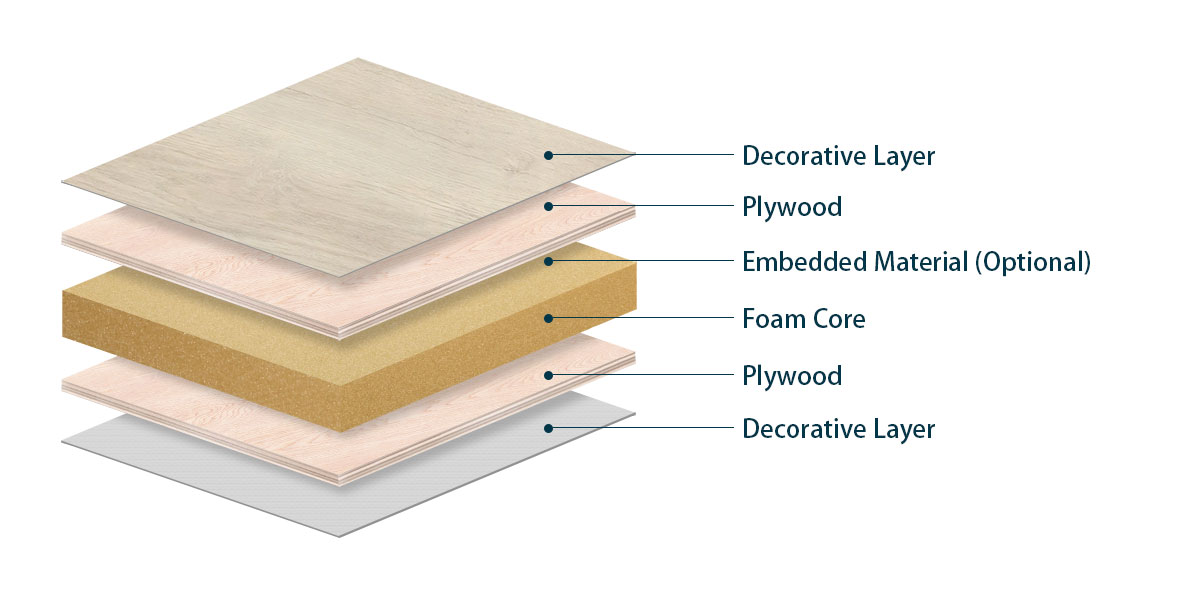

Structure Schematic

- Plywood Outer Layer: This layer provides the strength and stability of the sandwich panel, allowing it to carry loads and provide structural support.

- Foam Core: The function of the foam core is to increase insulation, reduce overall weight and provide shock absorption.

- Decorative Layer: Waterproof, corrosion-resistant treatment.

Basic Specifications

- Skin material: Plywood(Poplar, birch, oak, pine, eucalyptus, beech, etc.).

- Core material: XPS/PET/PU/PVC foam board.

- Length: within 12m.

- Width: within 3.2m.

- Thickness: 50~150mm.

Applications

- RV composite panels.

- Composite panels for box trucks.

- Floor.

- Door panel.

- Partition

- Cupboard.

- Ceiling.

- Bed board.

- Desktop.

- Chair panel, etc.,