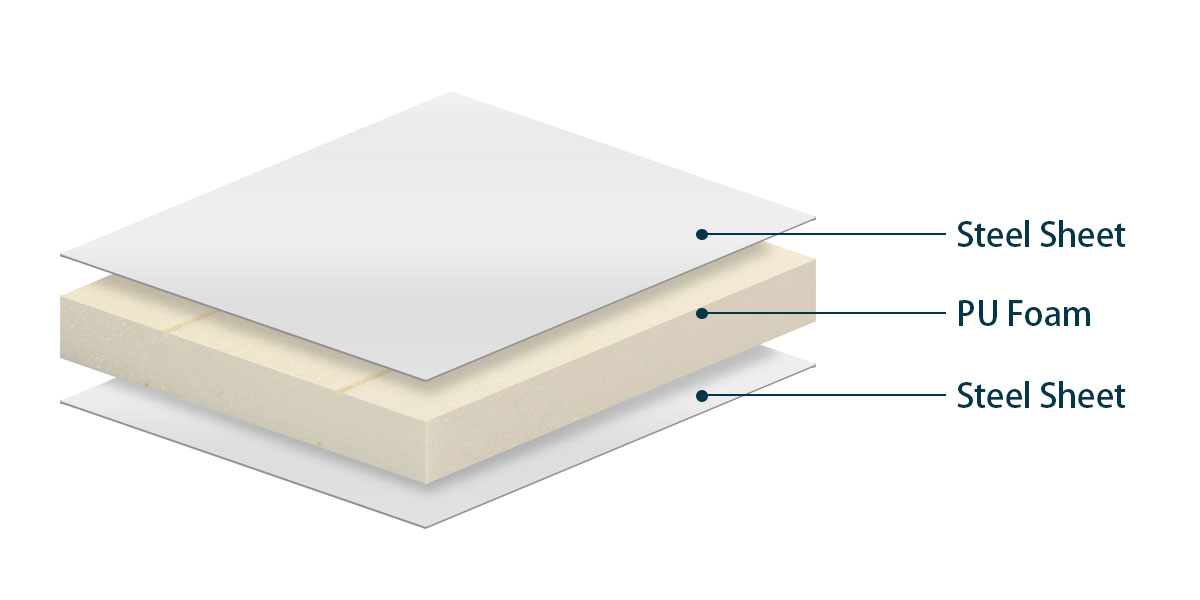

Steel skin PU sandwich panels are building materials used in construction and industrial fields. Its structure is very simple and is made of polyurethane (PU) foam core sandwiched between two layers of steel sheets. We use laminated composite technology to produce PU sandwich panels, using rigid closed-cell PU foam as the core material. Compared with sandwich panels made by the foam filling process, our composite panels are more flexible and suitable for various engineering projects.

Basic Specifications

| Skin Material | Galvanized steel, galvalume steel, PPGI (pre-painted galvanized steel), PPGL (pre-painted galvalume steel). |

| Total Thickness | 10~150mm. |

| Steel Sheet Thickness | 0.12~3.0mm. |

| Width | 600~1500 mm |

| Length | ≤12m |

| Steel grade | DX51D+Z, DX52D+Z, DC51D+Z, DC52D+Z, S350GD+Z, etc. |

| Surface Treatment | Large spangle, small spangle, no spangle. |

| Surface Color | RAL color, or customized pattern. |

| PU Foam Density | 40~85kg/m³. |

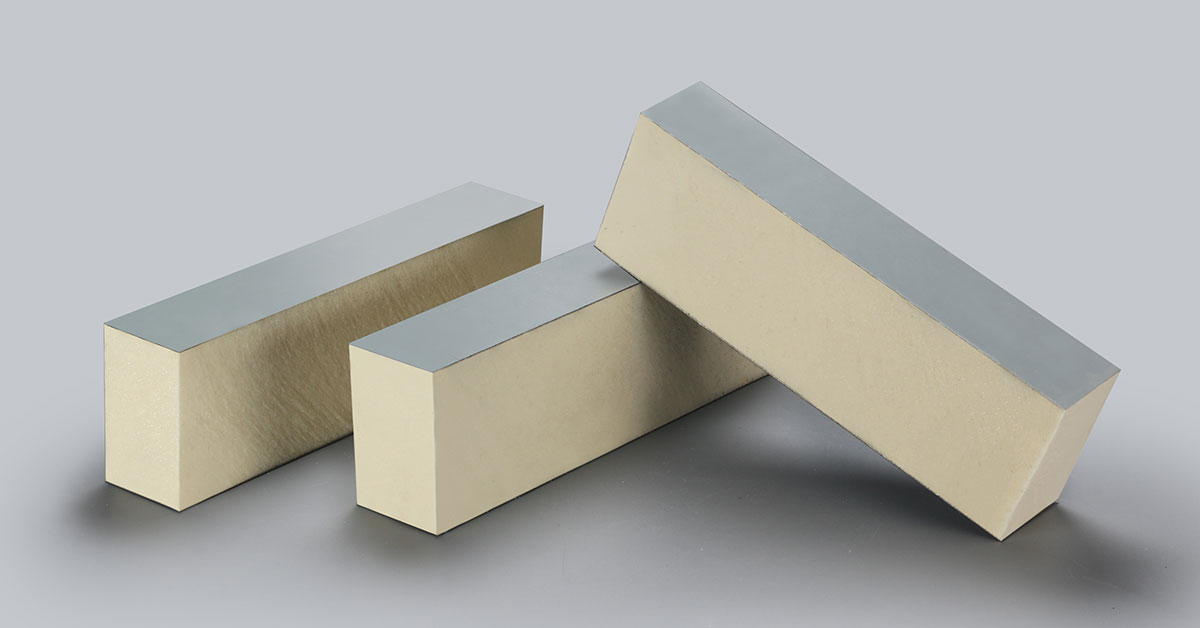

Galvanized/Aluzinc Skin PU Sandwich Panels

The surface of galvanized steel sheet is coated with a layer of zinc to achieve anti-rust effect, and the surface of galvalume steel sheet is coated with aluminum and zinc to achieve better anti-rust effect.

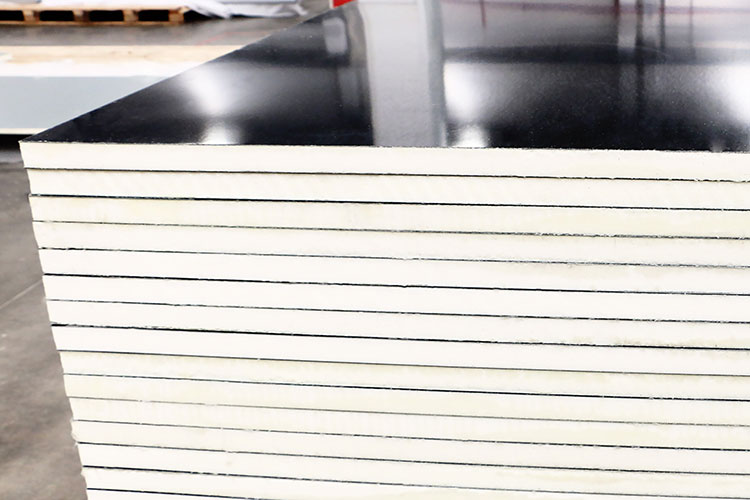

PPGI/PPGL Skin PU Sandwich Panels

PPGI (prepainted galvanized steel) / PPGL (prepainted galvalume steel) is to apply one or more layers of organic coatings (PVDF, HDP, SMP, etc) on the surface of galvanized or galvalume steel. They have better anti-corrosion properties and aesthetic appearance.

Our Product Advantages

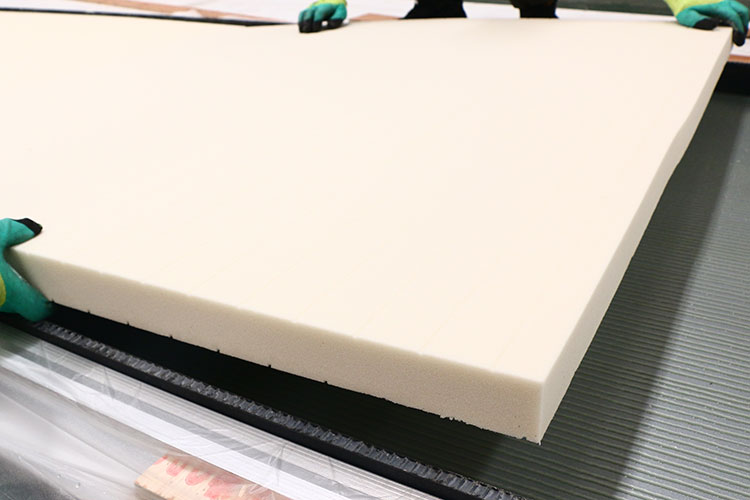

- High-quality raw materials: Corrosion-resistant high-galvanized coated base steel, the thickest coating is 275g/m² (single side); closed-cell flame-retardant PU foam core; lightweight and high-viscosity glue is used as the adhesive.

- Flexible sizes: We customize the size of the composite panels according to your project, up to 12m in length.

- Diversified composite solutions: The skin materials on both sides of the composite panel are diversified. You can use steel skin on one side and choose FRP, aluminum, stainless steel, plywood and other materials on the other side.

Application of Steel Skin PU Sandwich Panels

More and more buildings (such as mobile homes, cold rooms, warehouses, farms, etc.) choose modular construction and use PU sandwich panels to build houses. This not only simplifies the construction process and reduces labor costs, but also facilitates disassembly and installation. Importantly these materials can be reused, thus protecting the environment and reducing waste.