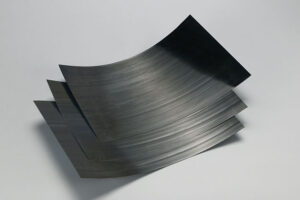

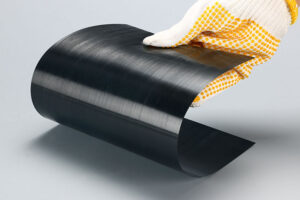

CPA6 carbon fiber UD tape is a continuous carbon fiber reinforced PA6 UD tape with 50% carbon fiber content. It is useful in car parts including accelerator, brake pedal, seat frame & seat base, etc.

- Low cost.

- Lightweight.

- High strength and modulus.

- Excellent impact resistance.

- No VOC, environmental, completely recyclable.

Description

What is UD Tape?

UD tapes (unidirectional prepreg tapes) are composite materials used to create lightweight, high-strength structures. They consist of fiber reinforcements (such as carbon fiber or fiberglass) pre-impregnated with a matrix material (usually resin). The fibers are aligned in a single direction to maximize strength in a specific direction. Prepreg tapes can be laid in specific directions to produce composite structures with specific mechanical properties. Unidirectional prepreg tapes are valued for their strength, toughness, and lightweight, making them ideal for high-performance applications.

Specifications

| Items | Standards | Condition | Unit | Value |

| Density | ISO1183 | 23℃ | g/cm3 | 1.38 |

| Fiber Content | ISO3451 | 23℃ | %wt | 50 |

| Tape Thickness | / | 23℃ | mm | 0.30 |

Mechanical Properties

| UD Tensile Strength | ISO527-3 | 10mm/min | MPa | 1200 |

| 0/90 Tensile Strength | ISO527-4 | 2 mm/min | MPa | 540 |

| UD Flexural Strength | ISO14125 | 5mm/min | MPa | 1200 |

| UD Flexural Modulus | ISO14125 | 5mm/min | MPa | 85000 |

| 0/90 Flexural Strength | ISO14125 | 5mm/min | MPa | 720 |

| 0/90 Flexural Modulus | ISO14125 | 5mm/min | MPa | 53200 |