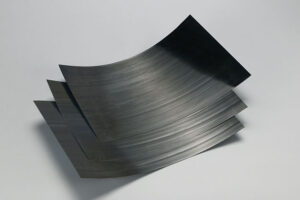

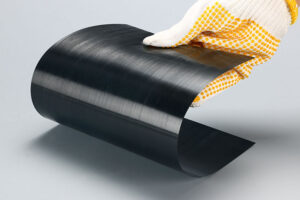

GPE UD tape is a glass fiber reinforced thermoplastic tape specially designed for RTP oil pipes. It is flexible, corrosion-resistant, high-pressure resistant, impact-resistant, wear-resistant, and lightweight. It can well overcome the corrosion problem of steel pipes and the pressure resistance problem of plastic pipes. It can be used in oil and natural gas mining, high-pressure long-distance transportation and various pipeline fields that require higher pressure transportation media.

- Type: GPE700, GPE800, GPE900.

- Resin: PE (Polyethylene).

- Fiber: Continuous glass fiber.

Description

What is UD Tape?

UD tapes (unidirectional prepreg tapes) are composite materials used to create lightweight, high-strength structures. They consist of fiber reinforcements (such as carbon fiber or fiberglass) pre-impregnated with a matrix material (usually resin). The fibers are aligned in a single direction to maximize strength in a specific direction. Prepreg tapes can be laid in specific directions to produce composite structures with specific mechanical properties. Unidirectional prepreg tapes are valued for their strength, toughness, and lightweight, making them ideal for high-performance applications.

GPE700 Series

| Items | Standards | Range | Unit | Value |

| Width | / | / | mm | 300±0.5 |

| Thickness | / | / | mm | 0.30±0.02 |

| Density | ASTM D792-08 | 1.5±0.05 | g/cm3 | 1.54 |

| Fiberglass Content | ASTM D5630 | 65±3 | %wt | 64.82 |

| Tensile Strength | ASTM D638 | ≧600 | MPa | 697 |

| Elongation at Break | ASTM D638 | ≧2.0 | MPa | 2.16

|

GPE800 Series

| Items | Standards | Unit | Value |

| Width | / | mm | 30~300 |

| Thickness | / | mm | 0.30±0.02 |

| Density | ISO1183 | g/cm3 | 1.63 |

| Fiberglass Content | / | %wt | 65 |

| Tensile Strength | ISO527-5/Tape | MPa | 800 |

| Tensile Modulus | ISO527-5/Tape | GPa | 29 |

| Elongation | ISO527-5/Tape | % | 2.5 |

| Flexural Strength | ISO14125 | MPa | 450 |

| Flexural Modulus | ISO14125 | GPa | 28 |

| Interlaminar Shear Strength | ISO14130 | MPa | 19 |

| X Orientation CLTE | ISO11359 | μm/(m. oC) | 10 |

| Y Orientation CLTE | ISO11359 | μm/(m. oC) | 126 |

| Z Orientation CLTE | ISO11359 | μm/(m. oC) | 115 |

| Melting Temperature | ISO11357 | oC | 128 |

| Glass Transition Temperature | ISO11357 | oC | -109 |

GPE900 Series

| Items | Standards | Unit | Value |

| Width | / | mm | 30~300 |

| Thickness | / | mm | 0.25±0.02 |

| Density | ISO1183 | g/cm³ | 1.72 |

| Fiberglass Content | / | %wt | 70 |

| Tensile Strength | ISO527-5/Tape | MPa | 900 |

| Tensile Modulus | ISO527-5/Tape | GPa | 35 |

| Elongation | ISO527-5/Tape | % | 2.5 |

| Flexural Strength | ISO14125 | MPa | 485 |

| Flexural Modulus | ISO14125 | GPa | 34 |

| Interlaminar Shear Strength | ISO14130 | MPa | 20 |

| X Orientation CLTE | ISO11359 | μm/(m. oC) | 11 |

| Y Orientation CLTE | ISO11359 | μm/(m. oC) | 108 |

| Z Orientation CLTE | ISO11359 | μm/(m. oC) | 177 |

| Melting Temperature | ISO11357 | oC | 128 |

| Glass Transition Temperature | ISO11357 | oC | -109 |

| Deflection Temperature | ISO75-2 | oC | 133 |