Product Specifications

- Total Thickness: 20.0mm. (Customized: 10~120mm)

- Length: ≤12m.

- Width: ≤2.8m.

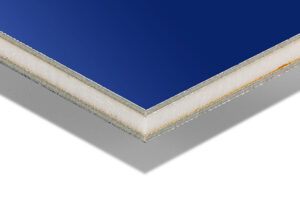

- Top Facing: 1.2mm matte CFRT sheet. (Customized: 0.7~2.0mm)

- Core Layer: 150kg/m³ PET foam. (Customized: 60~300kg/m³)

- Bottom Facing: 1.2mm matte CFRT sheet. (Customized: 0.7~2.0mm)

- Area Weight: 6.26kg/m².

- Applications: Dry Freight Trucks.

Description

What is CFRT Sheet?

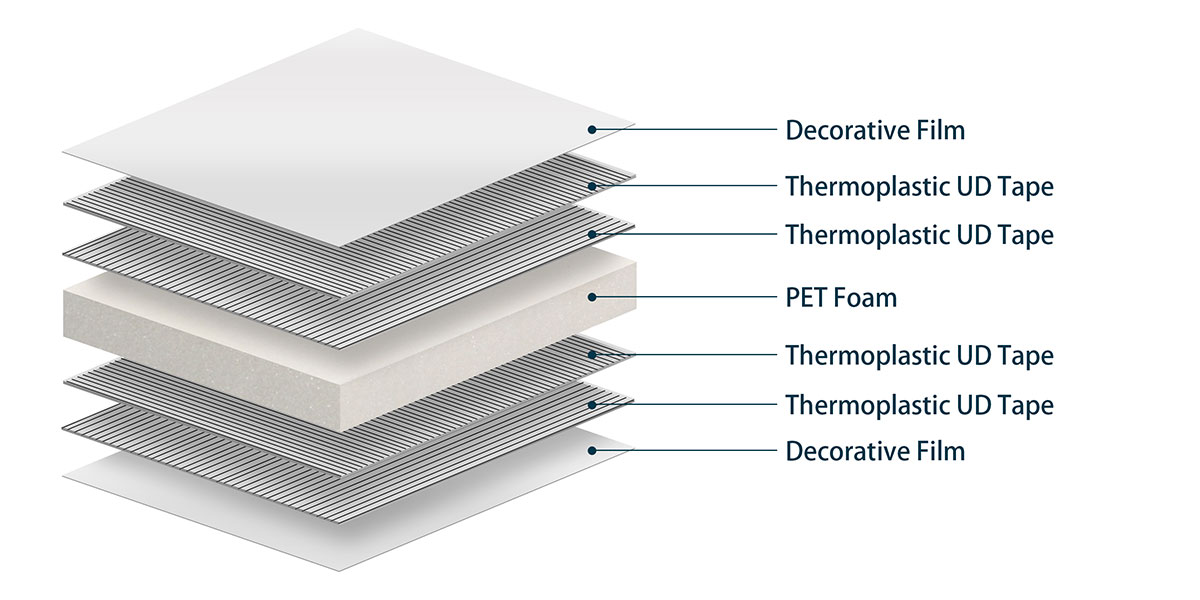

The continuous fiber thermoplastic composite sheet (CFRT) is made of double-layer or multi-layer thermoplastic unidirectional prepreg tapes at an angle of 0° or 90°, and then thermally laminated. CFRT sheet is a new type of thermoplastic composite material with high strength, high rigidity, high toughness and recyclability.

CFRT Facing PET Foam Sandwich Panels

Product Advantages

Dry cargo truck bodies made of PET sandwich panels have many advantages such as lightweight, high strength, corrosion resistance, and environmental protection. They are suitable for the dry cargo transportation industry and can improve transportation efficiency and reduce costs. They are a composite panel with development potential.

- Lightweight: Compared with traditional materials such as steel, it can reduce the weight of vehicles, reduce fuel consumption, and improve transportation efficiency.

- Strength: CFRT PET sandwich panels are lightweight and have high strength, and can withstand a certain load to ensure transportation safety.

- Corrosion resistance: CFRT PET sandwich panels have good corrosion resistance and can resist the effects of chemicals, moisture and climate changes on vehicles, extending their service life.

- Environmental protection: CFRT PET sandwich panels are recyclable and environmentally friendly materials, which meet the needs of modern society for environmental protection and reduce the consumption of natural resources.

Learn more about CFER PET Sandwich Panels.