Product Parameters

- Total Thickness: 54.0mm. (Customized: 10~120mm)

- Width: Max 2.8m.

- Length: Max 12m.

- Top Facing: 1.2mm CFRT sheet with PET film. (Customized: 0.7~2.0mm)

- Core Layer: 40kg/m³ XPS (Extruded Polystyrene) foam. (Customized: 35~50kg/m³).

- Bottom Facing: 1.2mm CFRT sheet with PET film. (Customized: 0.7~2.0mm)

- Area Weight: 6.4kg/m².

- Applications: Thermal insulation panels for refrigerated trucks.

Description

Continuous fiber reinforced thermoplastic composite sheet as the skin of composite panels is an innovation for the refrigerated truck manufacturing industry.

What is CFRT?

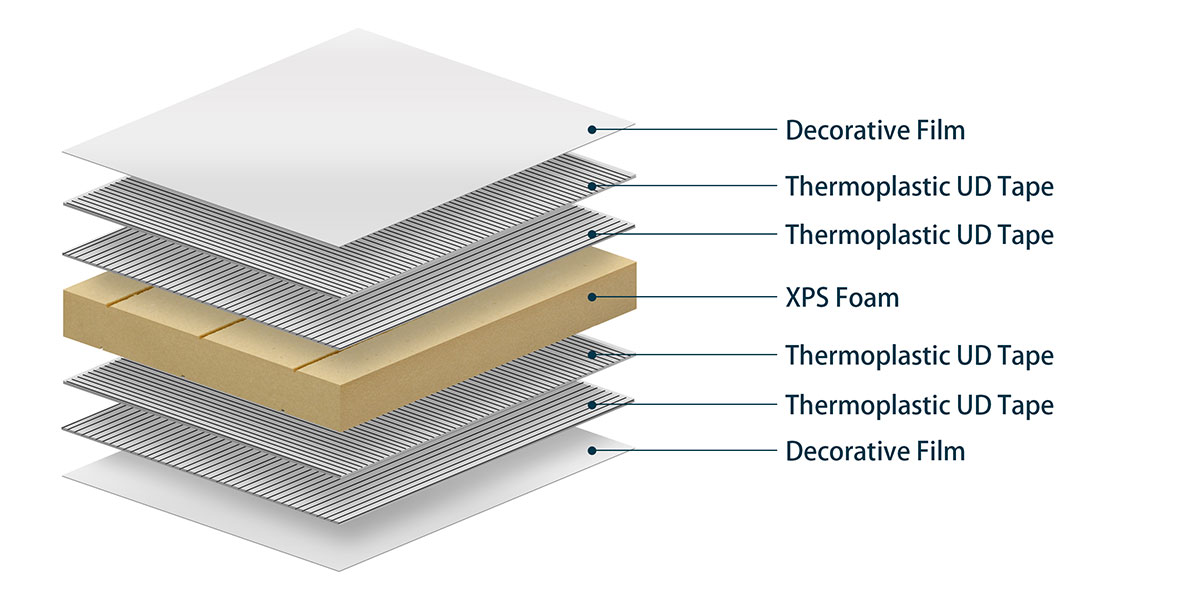

The continuous fiberglass thermoplastic composite sheet (CFRT) is made of double-layer or multi-layer thermoplastic unidirectional prepreg tapes at an angle of 0° or 90°, and then thermally laminated. CFRT sheet is a new type of thermoplastic composite material with high strength, high rigidity, high toughness and recyclability. Usually, its surface is covered with a decorative film and the back is covered with a layer of non-woven fabric. More

Schematic Diagram

Advantages compared to FRP skin composite panels

- More sturdy.

- More resilient.

- More wear-resistant.

- Lower cost.