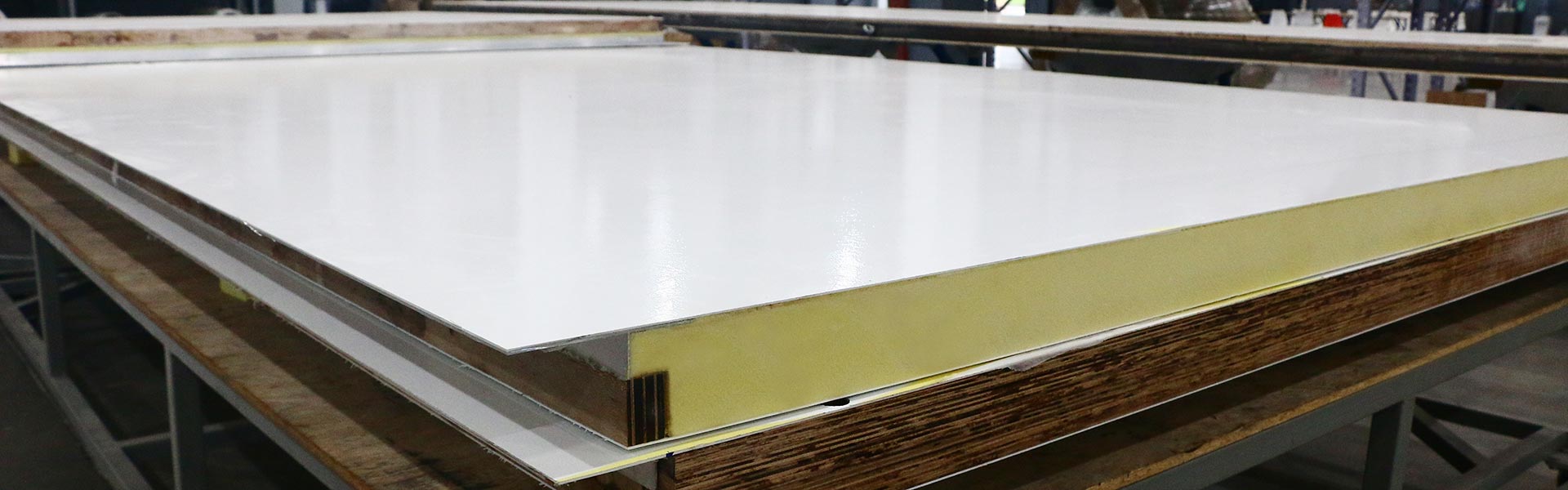

T-Panels supply GRP composite panels for all kinds of refrigerated trucks, dry cargo trucks. These materials include: PU foam sandwich panels, XPS foam sandwich panels, PET foam core sandwich panels, PP honeycomb core sandwich panels, etc. In addition to GRP skin materials, we also customize stainless steel, aluminum, galvanized steel, and plywood as skins for truck body composite panels.

Types of Truck Body Panels

- Due to the excellent thermal insulation performance of PU foam core, generally, PU foam core sandwich panels are used for the manufacture of refrigerated truck bodies.

- XPS foam not only has high thermal insulation performance, but also has high compression resistance and structural stability. Therefore, XPS foam core sandwich board is also one of the material choices for making fresh-keeping and refrigerated truck bodies.

- PET foam has high hardness and stable and reliable structural performance. Therefore, PET foam core sandwich panels are mostly used on dry freight trucks to replace traditional metal box trunks.

- PP honeycomb core sandwich panels are lightweight, high-strength, and have excellent compressive and bending properties. It is an excellent material for making lightweight dry freight truck boxes.

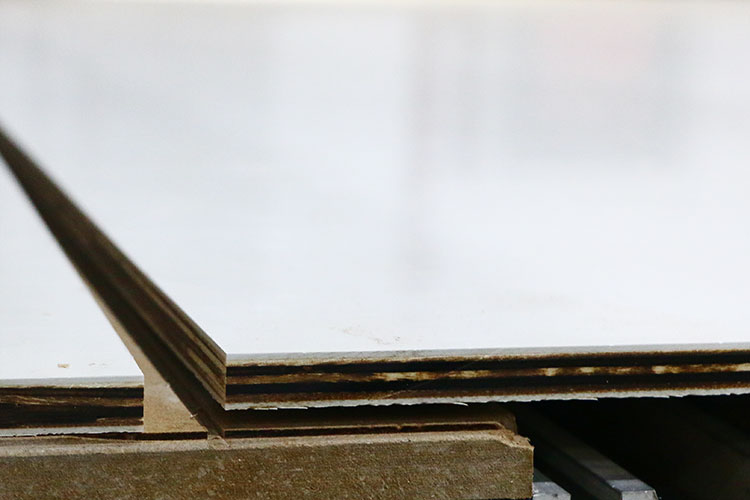

- Fiberglass plywood core sandwich board is a high-strength material that facilitates cutting and installing screws. Therefore, it is mostly used on dry cargo trucks.

Our Capacity Advantage

- In customized production, the maximum length of the panel is 12m, and the maximum width is 3.2m.

- One-piece composite panel production line with a daily production capacity of more than 1,000 square meters.

- 5-axis CNC machining, the minimum error of the length of the panel is within 1mm.