Whether used in the food supply chain or pharmaceutical storage, cold storage is an excellent choice. Nowadays, cold storage can realize intelligent control of temperature and humidity, providing the best fresh-keeping environment for your goods. As an important part of cold storage operation, the cold room door panel is also the focus of attention.

Basic Requirements for Cold Room Doors

- The cold room door should have good thermal insulation and air tightness, which can effectively prevent “cold bridges” in addition to preventing “cold bridges”.

- The cold room door should be light, open and close flexibly, and convenient for personnel to operate.

- It has a certain strength, is durable, does not deform, and is anti-collision.

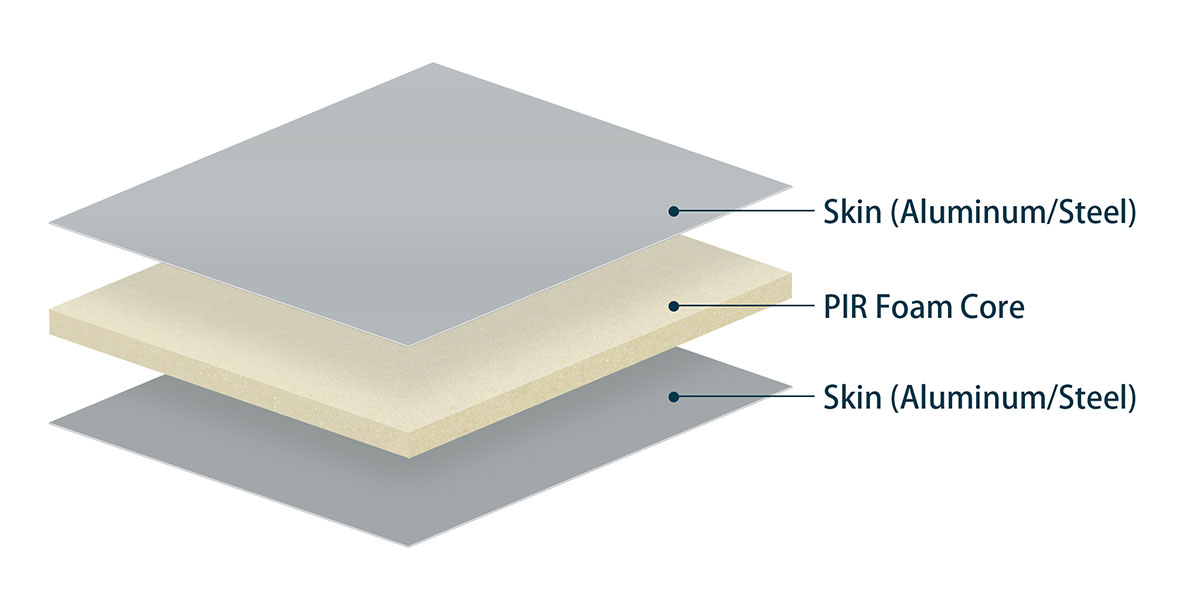

In order to achieve better thermal insulation effect, we recommend PIR foam color steel plate to you as the cold storage door panel material.

PIR is More Thermal Insulating Than PUR

As the fire protection grade requirements for thermal insulation sandwich panels become increasingly stringent, PUR faces huge challenges in meeting fire protection regulations. It is increasingly becoming a trend to use materials with higher fire safety performance, and the emergence of PIR just solves this problem. Compared with PUR, PIR performs better in many aspects.

- Good Thermal Insulation Effect: PIR foams evenly, has a thermal conductivity between 0.021 ~ 0.023, and has better thermal insulation performance. PIR sandwich panels can be used for a long time at temperatures below -150°C and will not shrink or become embrittled in low or even ultra-low temperature environments. Therefore, they are ideal materials for cold storage door panels.

- Flame-resistant and Fire-proof: The flame retardant grade of PIR is B1, which is flame retardant and has extremely low flammability. Compared with traditional PUR, PIR has higher fire safety performance and is the preferred material for cold storage door panels with high fire protection requirements.

- Waterproof and Moisture-proof: PIR foam core material is a closed-cell organic polymer foam material with a water absorption rate of only 0.9%. It has excellent waterproofness and resistance to water vapor permeability, and will not be eaten by insects or weathered.

- Efficient and Environmentally Friendly: PIR is non-toxic and odorless when burned, and the gas emitted is harmless to the human body and the environment. It is a new type of green, environmentally friendly and energy-saving material.

- Crash-resistant: It is a material with a relatively high strength ratio. As an insulation material, its performance is better than that of PU foam, rock wool and other materials, and its ability to resist external forces is also stronger. Using PIR as the core material of cold storage door panels can fully ensure the sturdiness of the cold storage.

Basic Specifications of Cold Room Door Panels

| Panel Thickness | 100, 120, 150, 200mm, or Customized. | ||

| Door Types | Hinged door, swing door, sliding door. | ||

| Panel Core | PIR foam (Density: 28~50kg/m³). | ||

| Panel Facing | Galvanized steel sheet, stainless sheet, aluminum sheet. (Thickness: 0.3~0.8mm). | ||

Features of Cold Room Doors

- Door Panel: Polyurethane foam sandwich panels have a flat and smooth appearance and good thermal insulation properties. It can keep the temperature inside the box between -45~+20°C.

- Door Frame: The door frame is made of high-quality stainless steel plates or alloy aluminum plates, and the sealing strips are made of high-quality rubber. There is a tight seal between the door frame and the door.

- Guiding Device (Sliding Door): The guide rail material is aluminum alloy, and the wheels work on the liner and track. When the door is started, the wheels can separate the door from the door frame. When the door is closed, the wheels can press the door and the door frame tightly.

Customize Your Cold Room Doors

Insulated Sliding Doors

- Door Thickness: mm/50mm/60mm/80mm/100mm.

- Density: 45kg/m³ rigid polyurethane, CFC free.

- Applications: cold room, workshop, factory, warehouse, etc.

- Accessories: handle, 0.6mm RAL9002 prepainted steel door skin, aluminum alloy door profiles.

- Options: electric system, lock, observation window, material ofpanel, surface color.

Lifting Doors

- Door Thickness: 4.0mm.

- Density: 45kg/m³ rigid polyurethane, CFC free.

- Applications: workshop, factory, warehouse, etc.

- Water Tightness: grade-1 ( water pressure 30pa).

- Weight of Door Panel: 14kg/m³.

Options: electric machine, observation window, surface color, a door within door. - Height of Door: 2000-8000mm.

- Width of Door: 2000-6000mm.

Low Temperature Sliding Doors

- Door Thickness: 120Rm/150mm.

- Density: 48-50kg/m³, rigid polyurethane, CFC free.

- Applications: cold room, warehouse, etc.

- Accessories: handle, 0.6mm RAL9002 prepainted steel skin, aluminum alloy door profiles.

- Options: electric system, material of panel, surface color.

Gas Tone Doors

- Door Thickness: 100mm

- Density: 48-50kg/m³, rigid polyurethane, CFC free.

- Applications: constant temperature storehouse, warehouse, etc.

- Accessories: handle, observation window, 0.6mm RAL9002 prepainted steel skin, aluminum alloy door profiles.

- Options: electric system, safety charge valve, material of panel, surface color.

Hinged Cold Room Doors

- Door Thickness: 60mm/80mm/100mm.

- Density: 45kg/m³, rigid polyurethane, CFC free.

- Applications: cold room, storage room, warehouse, and place where thermal insulations are required.

- Accessories: handle, escape lock, lift hinge, 0.6mm prepainted steel skin.

- Options: kick-plate, material of panel surface.

Provide us with your design drawings, and we will process the perfect product for you. Of course, you can also tell us your ideas. We have a professional design team to design products specific to your project.