As one of the important parts of the bus, the quality and safety of the bus floor cannot be ignored. Bus floors are typically designed to be strong, easy to clean, and durable because buses often carry large numbers of passengers and the floors are susceptible to wear and stains.

How to choose the right bus flooring?

- Durable: Bus floors are used by a large number of passengers and hauled by luggage, so strong materials are needed to extend the service life of the floor.

- Seat fixing points: There are usually seat fixing points on the floor for installing seats and seat brackets, so the floor must be able to firmly fix the seat.

- Lightweight: Overly heavy floors will consume more bus fuel and increase operating costs. Therefore, the floor should be as lightweight as possible.

Disadvantages of Traditional Bus Flooring

Traditional bus floors mostly use plywood or metals such as aluminum, stainless steel as the materials. Although they have their own advantages, but also have many insurmountable shortcomings.

- Plywood: Plywood is made of relatively thin wooden veneers. It has many shortcomings due to the inherent defects of wood. It is heavy, easy to rot, easy to deform, and has a short service life. As the bus floor, plywood may have been a good material twenty or thirty years ago, but now it seems to lack quality and environmental protection.

- Metal: The metals commonly used to construct bus floors are aluminum and stainless steel, and their flaws are obvious. The installation of metal floors requires a lot of manpower and material resources, which is very troublesome and the overall construction cost is also high. In addition, bus floors made of metal have high thermal conductivity and are prone to rust and corrosion.

New Composite Panels for Bus Floors

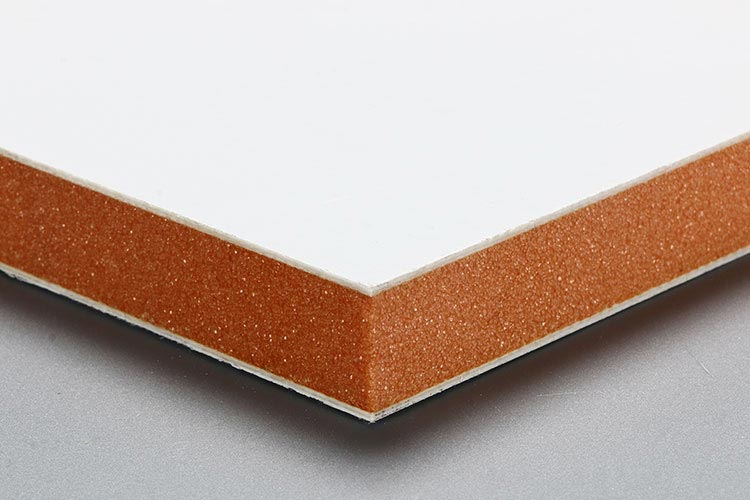

The new composite flooring we launched – fiberglass PET foam sandwich panels and PVC foam core sandwich panels with more superior performance. Both PET and PVC are closed-cell rigid foams that do not absorb water and are lightweight. The composite panels formed by combining them with fiberglass have good compressive, bending and tensile strength. This gives them a convenient performance advantage over traditional metal and wood flooring.

Their advantages for bus manufacturers are:

- Lightweight and high strength: Sandwich structure of foam and foam core provides stable support performance.

- Economical: Lower price than aluminum, stainless steel and plywood.

- Easy to process: Fiberglass sheet and rigid foam are easy to cut and process, reducing the difficulty of installation.

Additional Services

The surface of fiberglass composite panels can be covered with various plastic surface materials to provide anti-slip, waterproof, shock absorption, sound insulation and other functions.