How to solve the problem of long-distance and long-term transportation of refrigerated trucks while maintaining the low temperature inside the box. In addition to using high-power refrigeration equipment, it is particularly important to choose high-quality box materials. Fiberglass-reinforced skin PU foam sandwich panels are the first choice in this regard.

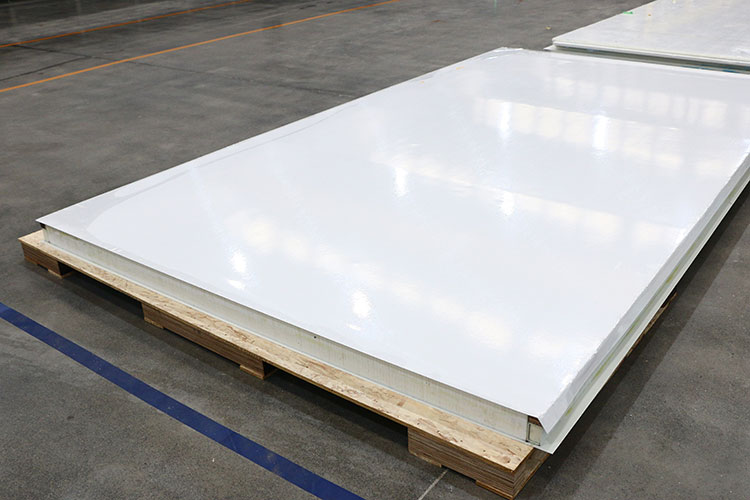

FRP PU sandwich panels

FRP PU sandwich panels are widely used in the manufacture of various vehicles that require thermal insulation, such as refrigerated trucks, freezers, and insulated trucks, providing good protection for the transportation and storage of temperature-sensitive goods. It usually consists of two layers of FRP sheets sandwiched with a layer of PU foam.

What are the advantages of FRP PU sandwich panels?

- Lightweight and high strength: The sandwich structure makes the board both lightweight and high-strength, providing good structural support performance while reducing the weight of the entire vehicle.

- Excellent insulation properties: Polyurethane foam has good thermal insulation properties, which can effectively isolate the internal and external temperatures and maintain a stable low-temperature environment inside the cabin.

- Good corrosion resistance: Fiberglass panels have excellent corrosion resistance and are not easily eroded by chemical substances, and can maintain long-term stable appearance and performance.

- Compression and bending resistance: The sandwich structure gives the plate better compression and bending resistance, increases the load-bearing capacity of the body, and improves the safety of the entire vehicle.

- Beautiful appearance: FRP panel has beautiful appearance and is easy to clean and maintain.

All in all, using FRP PU foam sandwich panels is not only safe and reliable, but also reduces energy consumption and has low maintenance costs.

New Fiberglass Sandwich Panels – CFRT PU Sandwich Panels

In addition to using thermosetting GRP sheets, we have developed a new type of fiberglass sheet for refrigerated body skins – CFRT, which is a continuous fiberglass reinforced thermoplastic material with higher strength and more stable performance. Learn more about CFRT sheet.

Compared with FRP, the advantages of CFRT are also reflected in:

- Continuous fibers provide higher compressive and flexural strength.

- There is a protective film on the surface, which is scratch-resistant and leaves no marks.

- Carbon black particles can be added to enhance UV resistance.

- The price is lower than FRP material and more economical.

- Longer service life than FRP.

Our Customizable Refrigerated Truck Panels

- The maximum size is up to 12m.

- The maximum width can reach 3.2m.

- Thickness: 10~120mm.

- The surface can be selected as high-gloss or matt.

And We Provide Reliable Design Solutions

- The periphery of the refrigerated truck side panels uses a fully enclosed design to enhance the panel’s tear resistance.

- A frame composite material is embedded inside the panel to increase structural strength.

- High-precision CNC machines are used to machine the shape of the panels.

Learn More About Refrigerated Truck Panels

-

29mm GRP Laminated PU Sandwich Panel for Refrigerated Box

29mm GRP Laminated PU Sandwich Panel for Refrigerated Box -

100 mm GRP XPS Foam Sandwich Panels for Refrigerated Trucks

100 mm GRP XPS Foam Sandwich Panels for Refrigerated Trucks -

50mm GRP Faced Polyurethane Foam Core Sandwich Panels for Refrigerated Trucks

50mm GRP Faced Polyurethane Foam Core Sandwich Panels for Refrigerated Trucks -

45mm CFRT Faced Polyurethane Foam Core Sandwich Panels for Refrigerated Trucks

45mm CFRT Faced Polyurethane Foam Core Sandwich Panels for Refrigerated Trucks -

54mm CFRT Skin XPS Foam Core Sandwich Panels For Refrigerated Trucks

54mm CFRT Skin XPS Foam Core Sandwich Panels For Refrigerated Trucks