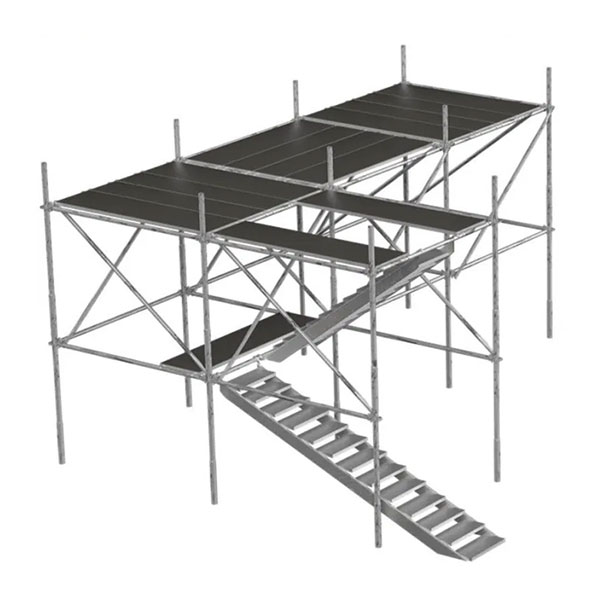

Mobile scaffolding platforms are used to support the work of operators and complete the construction and maintenance of man-made structures such as buildings, bridges, and interior decorations. However, since it is a high-altitude operation, safety accidents such as falling and overturning are prone to occur. How to better improve the safety of scaffolding has also attracted more and more attention. Ordinary scaffolding planks are mostly made of diamond aluminum alloy plates or plywood, but their flaws are also self-evident. To this end, TOPOLO developed anti-slip thermoplastic composite PP honeycomb panels for scaffolding planks.

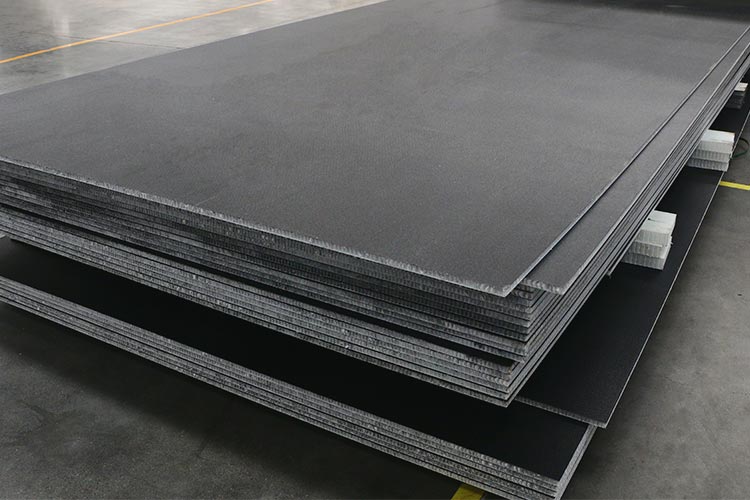

Anti-slip Thermoplastic Scaffolding Planks

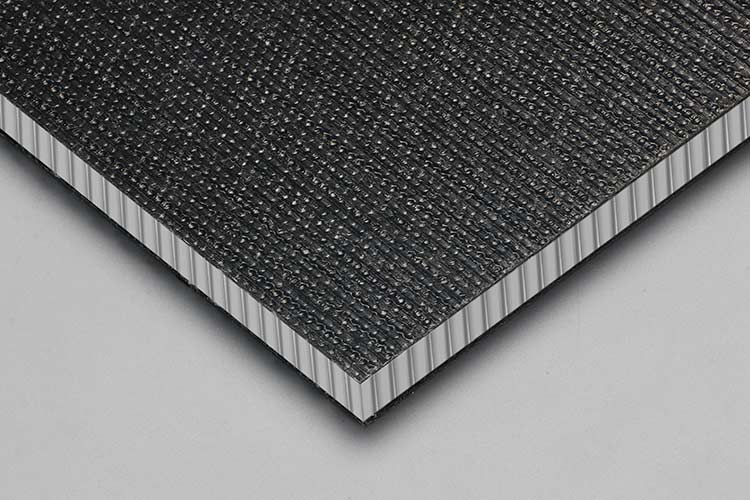

Anti-skid thermoplastic PP honeycomb panels have structural strength and anti-skid effects that are not inferior to those of plywood and diamond aluminum alloy. Its surface layer is a continuous fiberglass thermoplastic composite panel material with a non-slip texture. It has excellent properties of high strength, scratch resistance, waterproof and corrosion resistance. The internal core material is PP (polypropylene) honeycomb core, which is a lightweight material. All in all, using non-slip thermoplastic honeycomb panels as a plank for scaffolding is a safer and more economical option.

Feature of Product

- High-strength Structural Material

Thermoplastic PP honeycomb panel combined with 304 food-grade high-strength stainless steel (brackets, edge strips, plank hooks) structure.

- Highly Modular Structure

Our scaffolding planks adopt a modular structure, which is fast and simple to assemble and can be assembled by just one person in a short time. If a component is damaged or cracked, you can disassemble and replace an individual part rather than the entire scaffold.

- Simple and Practical

The scaffolding plank is fixedly connected by flat-head nuts and bolts. The deck surface is flat without any protrusions, making it safe and practical.

- High Load Capacity

Scaffolding is rated to withstand possible toppling, providing unparalleled strength and stability.

VS Wood Scaffolding Planks

Scaffolding boards made of wood don’t last long. Wood is not waterproof and is more susceptible to rot. It also cannot withstand the local impact of gravity, which can easily cause pits, cracks, etc. on the surface of the scaffolding plank. These problems will leave safety hazards.

VS Aluminum Scaffolding Planks

The manufacturing cost of scaffolding planks with aluminum alloy decking is higher. Its anti-skid effect comes from the convex texture on the surface. After long-term use, the surface will be worn and become smooth, thus losing the anti-skid effect. Additionally, it presents the risk of conducting electricity.

Learn more about non-slip thermoplastic honeycomb panels

- High strength.

- Lightweight.

- Wear-resistant.

- Waterproof.

- Corrosion resistant.

- Affordable.

- Anti-UV.

- Easy to assemble.

Our Unique Advantages

Advanced thermoplastic production line

Our factory has the latest thermoplastic composite production line in the world, which can produce high-quality continuous fiber-reinforced thermoplastic composite sheets and panels at ultra-high speed.

Transportation and Cooperation

We provide customized services to scaffolding dealers and wholesalers around the world. And customize solutions for every packaging and transportation.