Product Specifications

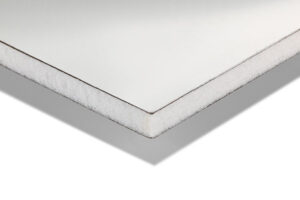

- Total Thickness: 13.0mm. (Customized: 5.0~120mm)

- Length: ≤12m.

- Width: ≤2.6m.

- Top Facing: 1.5mm aluminum sheet. (1100, 3003, 3004, etc.)

- Core Layer: 80kg/m³ PET foam. (Customized: 60~300kg/m³)

- Bottom Facing: 1.5mm aluminum sheet. (1100, 3003, 3004, etc.)

Description

Product Advantages

- High strength to weight ratio

Aluminum skin foam sandwich panels have an extremely high strength-to-weight ratio, providing high strength while remaining lightweight.

- Corrosion resistance

Aluminum is naturally corrosion-resistant and can withstand most environmental factors, extending the material’s life and reducing maintenance costs.

- Excellent impact resistance

The combination of aluminum skin and foam core effectively absorbs and disperses impact energy, providing excellent impact resistance. This is very important in transportation and protective applications.

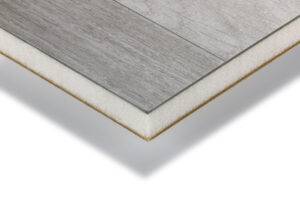

- Excellent flatness and appearance

The surface of aluminum skin is flat and smooth, has good aesthetics, is easy to process and paint, and can meet various decoration needs.

- Easy to process

Aluminum skin foam sandwich panels can be processed through cutting, drilling, gluing and other processes to adapt to different design and manufacturing needs.

- Environmental friendly

Both aluminum and PET foam materials can be recycled, helping to reduce environmental burden and meet the requirements of sustainable development.

Schematic Diagram

Application Areas

- Construction industry: Curtain walls, roofs, wall panels and partitions.

- Transportation: Body and interior panels in trucks, trains and ships.

- Industrial equipment: Manufactures machinery enclosures and equipment covers to provide protection and aesthetics.