Product Parameters

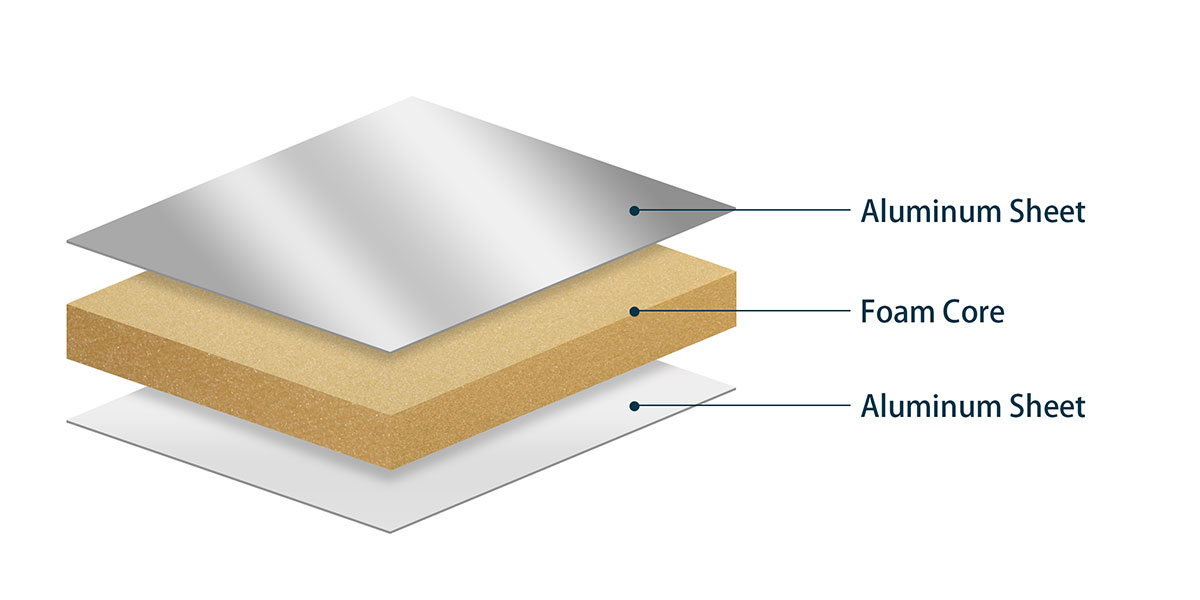

- Total Thickness: 26.0mm. (Customized: 10~120mm)

- Length: ≤12m.

- Width: ≤3.2m.

- Top Facing: 0.5mm Gray 3003 aluminum sheet. (Customized: 0.1~3.0mm)

- Core Layer: 35kg/m³ XPS(extruded polystyrene) foam. (Customized: 35~50kg/m³)

- Bottom Facing: 0.5mm White 3003 aluminum sheet. (Customized: 0.1~3.0mm)

- Surface Color: RAL series.

Description

Advantages of aluminum foam sandwich panels

- Lightweight and high strength: Due to the light weight of aluminum and the low density of foam plastic, aluminum skin foam sandwich panels have a lighter overall weight but higher strength, making them suitable for various construction and decoration applications.

- Thermal and sound insulation: The foam layer has good thermal and sound insulation properties, helping to maintain a comfortable temperature and quiet environment inside the building.

- Corrosion resistance: Aluminum plates have excellent corrosion resistance and can be used in various harsh environments for a long time, such as moisture, acid and alkali, etc.

- Easy to process: Aluminum skin foam sandwich panels are easy to cut, drill, bend and install. They can be customized and processed according to the needs of architectural design, simplifying the construction process.

- Environmental protection: Foam plastics usually use environmentally friendly materials, and aluminum can be recycled and reused, so aluminum foam sandwich panels have better environmental performance.

- Beautiful appearance: The aluminum foam sandwich panel has a flat, smooth surface and rich colors, which can meet the needs of different architectural decorations.

- Easy maintenance: Aluminum skin foam sandwich panels have a smooth surface and are easy to clean, requiring almost no additional maintenance.

Learn More Aluminum Facing XPS Foam Sandwich Panels