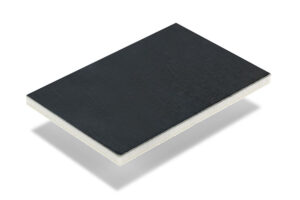

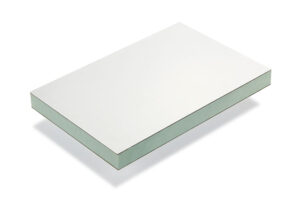

Product Specifications

- Total Thickness: 20.0mm. (Customized: 5.0~120mm)

- Length: ≤12m.

- Width: ≤2.8m.

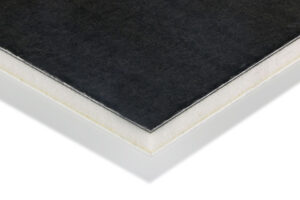

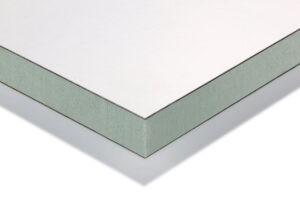

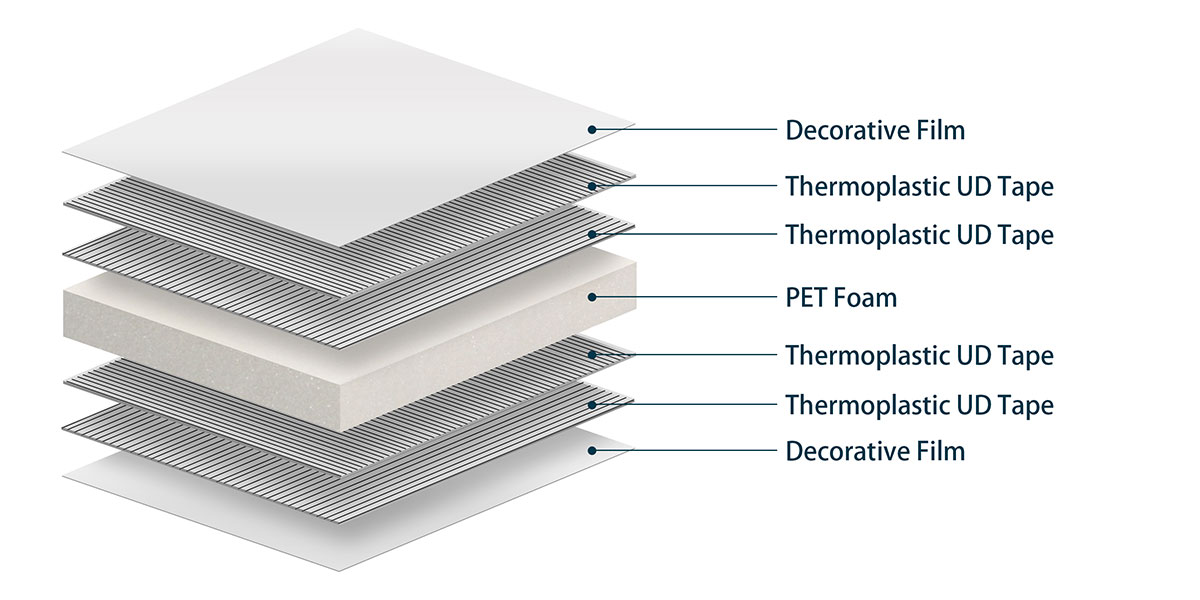

- Top Facing: 1.2mm CFRT sheet. (Customized: 0.7~2.0mm)

- Core Layer: 100kg/m³ PET foam. (Customized: 60~300kg/m³)

- Bottom Facing: 1.2mm CFRT sheet. (Customized: 0.7~2.0mm)

- Surface Treatment: Matte/Gloss PET film.

- Area Weight: 5.2kg/m².

Description

The production method of thermoplastic composite PET sandwich panels is different from other foam sandwich panels. No adhesive is used in its production process. It is manufactured by thermal fusion (heating melts the thermoplastic skin to composite it with the PET core material) . This is a disruptive and innovative method of manufacturing foam sandwich panels that not only has more stable performance but is also cheaper.

Manufacturing thermoplastic PET sandwich panels

Applications

RV floors, RV bodies, dry cargo truck bodies, interior partitions, cargo boxes, etc.