Travel Trailer Composite Panels

Travel trailers are more flexible and can be driven by different vehicles. Moreover, this type of RV is relatively cheap and is favored by travel enthusiasts from all over the world. We can customize one-piece travel trailer composite panels to specific requirements, making building your RV even easier.

One-piece Composite Panels

- Thickness: 10~120mm.

- Length: Max12m.

- Width: Max 3.2m.

- Size Tolerance: ≤1.0m.

- Thickness Tolerance: ≤0.1mm.

Guaranteed Performance

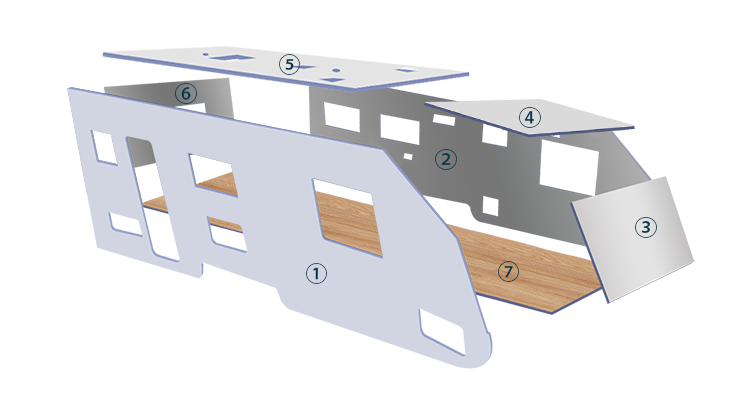

Side Panels, Roof Panels, Front Panels, Rear Panels.

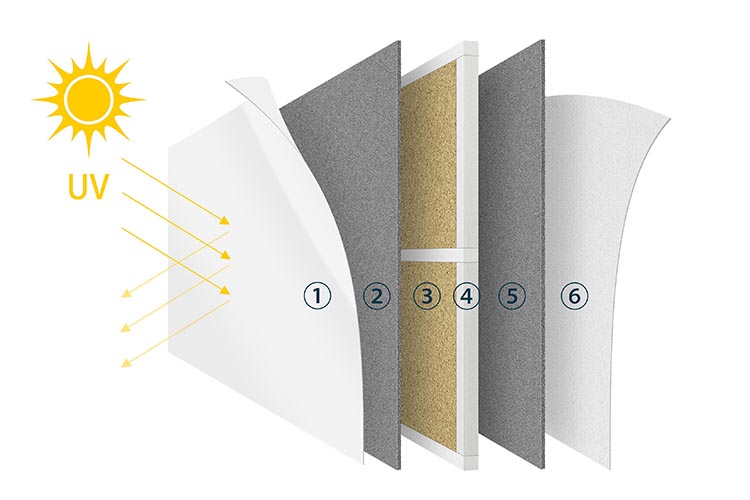

One-piece composite panel processing technology, the core material is tightly combined with the facing layer, and will not delaminate or deform.

①⑥:UV-resistant gel-coat FRP sheets; Glossy laminated film CFRT sheets; Aluminum alloy sheets.

②⑤:High temperature resistant isolation layer.

③: Thermal insulation foam (XPS, PET, PU, PVC, etc.).

④:Embedded frame. (Waterproof timbers, aluminum profiles, fiberglass profiles, etc.)

Floor Panels

The imitation wood grain PVC leather facing provides a more comfortable foot experience and is easier to clean and maintain.

①:Wood Grain PVC Leather. (Customized wood grain pattern.)

②⑤: FRP Sheets; CFRT Sheets; Aluminum alloy sheets.

③: Foam (XPS, PET, PU, PVC, etc.).

④: Plywood (Optional).

More Customized Services

To learn more about travel trailer composite panels, contact us for the best solution.